Environment-friendly offset ink and preparation method thereof

An environment-friendly, offset printing ink technology, applied in ink, household utensils, applications, etc., can solve the problems of insufficient solubility and permeability, and achieve the effects of easy degradation and regeneration, good printability, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

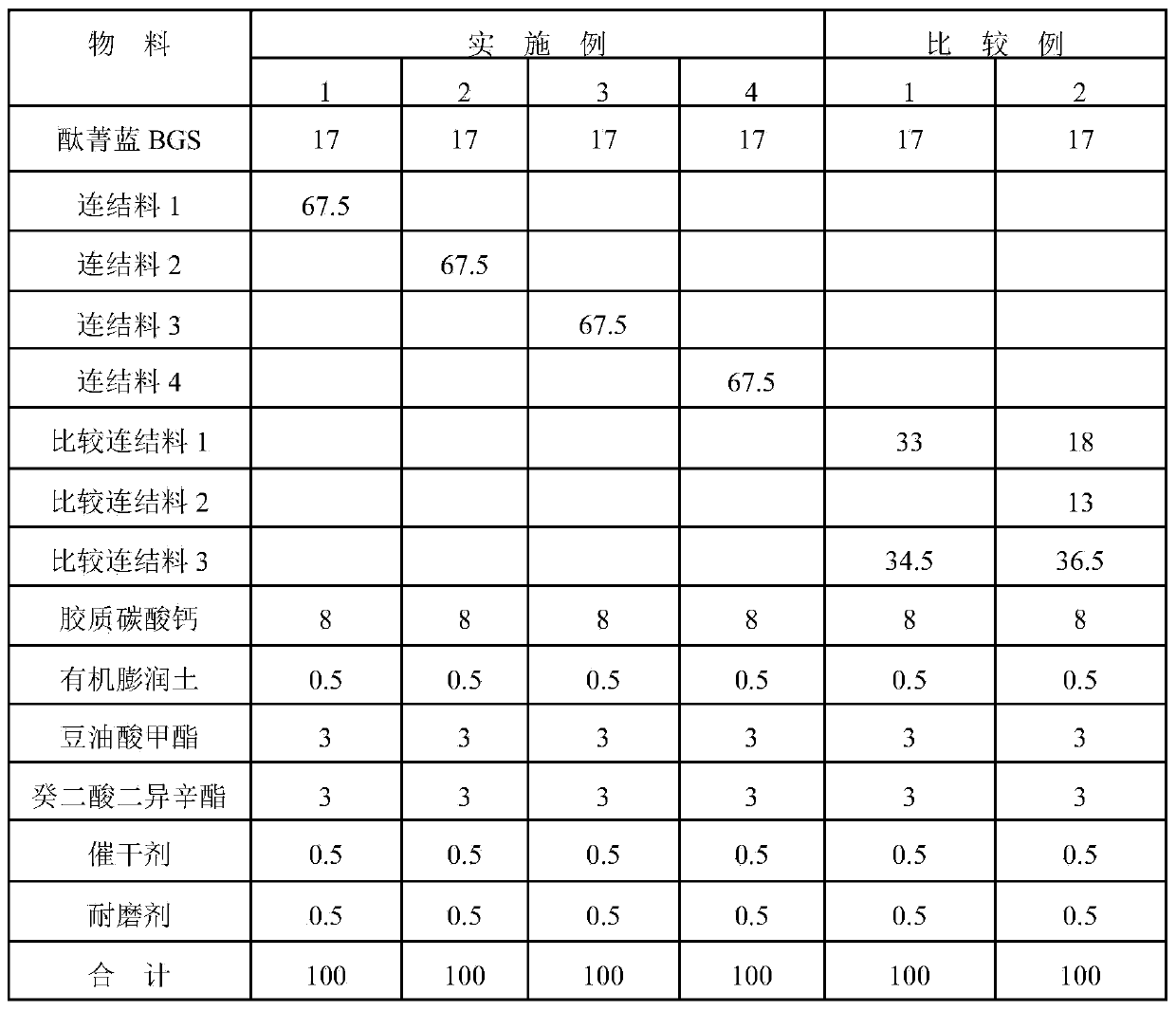

Examples

manufacture Embodiment 1

[0025] Add softening point ≥ 160°C, acid value ≤ 25mg / g, viscosity (8000-12000) mPa·s / 25°C (resin: linseed oil = 1:2 linseed oil resin solution), n-heptane to the four-necked flask 28 parts of rosin-modified tert-butylphenol phenolic resin with tolerance ≥4ml / 2g·25℃ (resin: linseed oil=1:2 linseed oil resin solution), softening point ≥150℃, acid value ≤15mg / g, viscosity (1000-3000) mPa·s / 25°C (resin: linseed oil = 1:2 linseed oil resin solution), n-heptane capacity (30-35) ml / 2g·25°C (resin: linseed oil = 1 12 parts of polymerized rosin pentaerythritol ester, 30 parts of refined soybean oil, and 15 parts of methyl soyate, heated up to 170 ° C until the contents of the bottle were melted evenly without solid lumps, and stirred and Under nitrogen protection, continue to heat up to 220°C, and keep warm at 220°C±2°C for 1 hour; stop heating, add 9.4 parts of butyl oleate, cool down to 140°C, add 0.5 parts of gelling agent, 0.1 part of BHT, and heat slowly Raise the temperature to...

manufacture Embodiment 2

[0027] Add softening point ≥ 163°C, acid value ≤ 25mg / g, viscosity (11000-15000) mPa·s / 25°C (resin: linseed oil = 1:2 linseed oil resin solution), n-heptane to the four-necked flask 28 parts of rosin-modified octylphenol phenolic resin with a tolerance of (7-15)ml / 2g·25°C (resin: linseed oil = 1:2 linseed oil resin solution), softening point ≥ 150°C, acid value ≤ 15mg / g, viscosity (1000-3000) mPa·s / 25°C (resin: linseed oil = 1:2 linseed oil resin solution), n-heptane tolerance (30-35) ml / 2g·25°C (resin: Linseed oil = 1:2 linseed oleoresin solution), 10 parts of polymerized rosin pentaerythritol ester, 32 parts of refined soybean oil, 14.8 parts of methyl soyate, heated up to 170 ° C until the contents of the bottle melted evenly without solid lumps , start stirring and nitrogen protection, continue to heat up to 220°C, and keep warm at 220°C±2°C for 1 hour; stop heating, add 9 parts of methyl soyate, cool down to 140°C, add 0.7 parts of gelling agent, BHT0.1 Heat slowly to 1...

manufacture Embodiment 3

[0029] Add softening point ≥ 160°C, acid value ≤ 25mg / g, viscosity (8000-12000) mPa·s / 25°C (resin: linseed oil = 1:2 linseed oil resin solution), n-heptane to the four-necked flask 30 parts of rosin-modified tert-butylphenol phenolic resin with tolerance ≥4ml / 2g·25°C (resin: linseed oil=1:2 linseed oil resin solution), softening point ≥150°C, acid value ≤15mg / g, viscosity (1000-3000) mPa·s / 25°C (resin: linseed oil = 1:2 linseed oil resin solution), n-heptane capacity (30-35) ml / 2g·25°C (resin: linseed oil = 1 10 parts of polymerized rosin pentaerythritol ester, 30 parts of refined soybean oil, and 10 parts of methyl soyate, heated up to 170 ° C until the contents of the bottle melted evenly without solid lumps, started stirring and Under nitrogen protection, continue to heat up to 220°C, and keep warm at 220°C±2°C for 1 hour; stop heating, add 4.8 parts of methyl soyate and 9.4 parts of diisooctyl sebacate, cool down to 140°C, and add gelling agent 0.7 part, BHT 0.1 part, heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com