A low-concentration oxygen-enriched fluidized suspension combustion method of coal-water slurry and its boiler device

A technology of suspension combustion and boiler installation, which is applied to combustion methods, fluidized bed combustion equipment, and fuels burned in a molten state, etc., can solve the problems of increased NOx generation and emission, complicated oxygen-enriched preparation equipment, and insufficient adaptability. The effect of reducing fuel ignition temperature, improving ignition and combustion conditions, and reducing exhaust heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The method and device of the present invention will be further described in detail below with reference to the drawings and embodiments.

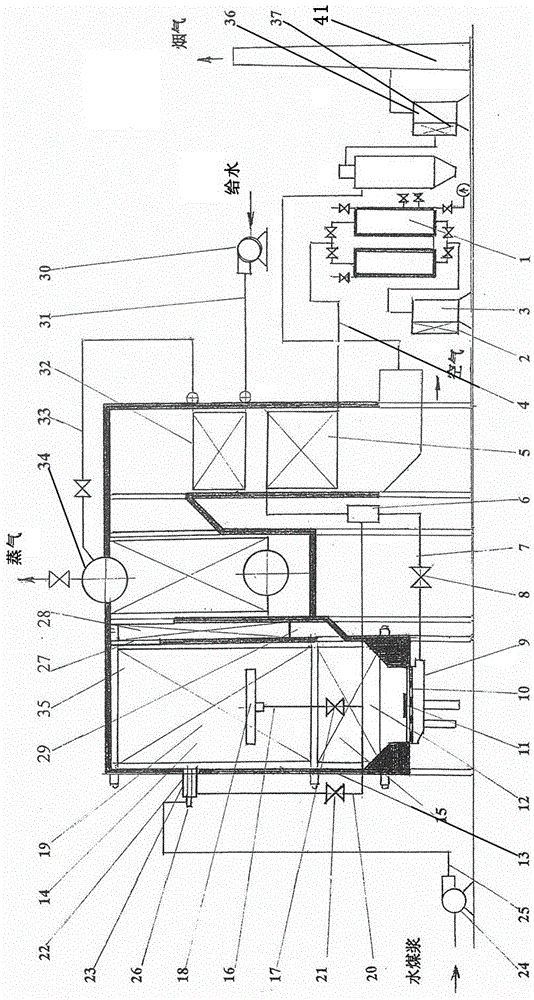

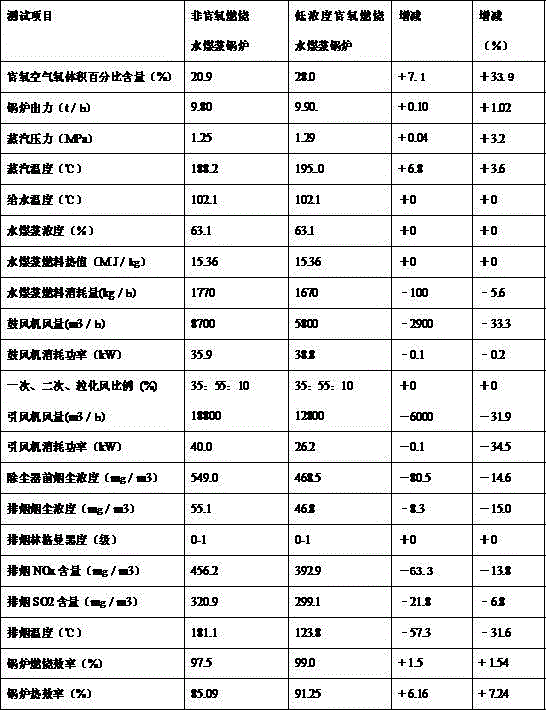

[0026] like figure 1 , figure 2 As shown, the implementation was carried out on a 10 t / h fluidized suspension combustion coal-water slurry boiler, and the traditional air-supported fluidized suspension combustion combustion coal-water slurry boiler was changed to a low-concentration oxygen-enriched combustion-supported fluidized suspension combustion coal-water slurry boiler boiler.

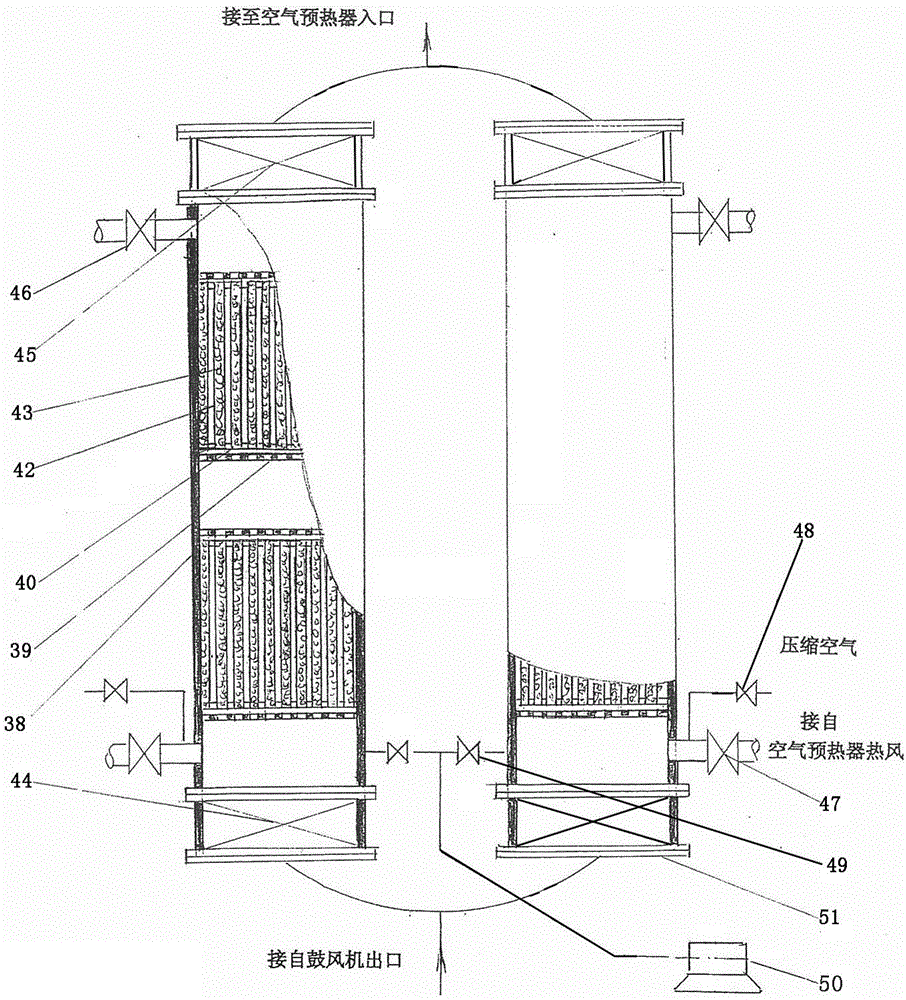

[0027]A coal-water slurry low-concentration oxygen-enriched fluidized suspension combustion boiler device is provided with a fluidized suspension combustion system, which includes a combustion chamber 14, a low-concentration oxygen-enriched air supply system attached to the combustion chamber 14, and the combustion chamber 14 Connected coal-water slurry supply system; low-concentration oxygen-enriched air supply system The inlet of the blower 3 is eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com