Bipolar electrode electrogenerated chemiluminescence paper based micro-fluidic chip and imaging sensing application thereof

A microfluidic chip, electrochemistry technology, applied in the direction of chemiluminescence/bioluminescence, analysis through chemical reaction of materials, chemical instruments and methods, etc., can solve the problem of high requirements for detection equipment, expensive gold materials, etc. and other problems, to achieve the effect of reducing signal interference, low equipment price, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a paper-based microfluidic chip with bipolar electrode electrochemiluminescence, comprising the following steps:

[0032] (1) Adobe Illustrate CS5 software was used to design the patterns of microfluidic channels (including solution storage pools) and electrodes (including working electrodes and driving electrodes), and the microfluidic channel grids and driving electrode grids were processed by the manufacturer.

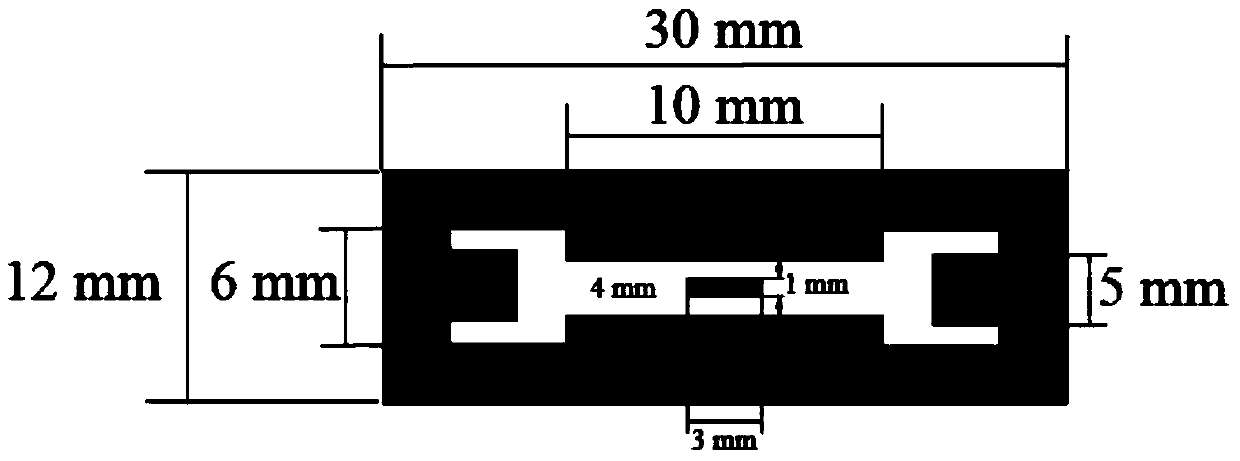

[0033] The size of the microfluidic channel is 10×4mm, the size of the driving electrode is 5×5mm, the size of the working electrode is 3×1mm, and the size of the whole paper-based microfluidic chip is 30×12mm. The detailed dimensions of the chip are as figure 1 shown.

[0034] (2) First, cut the No. 1 Whatman filter paper to the size suitable for the channel screen. Then, using conductive carbon paste as the material, the electrodes are screen-printed on the filter paper through the electrode screen. After the printing is completed,...

Embodiment 2

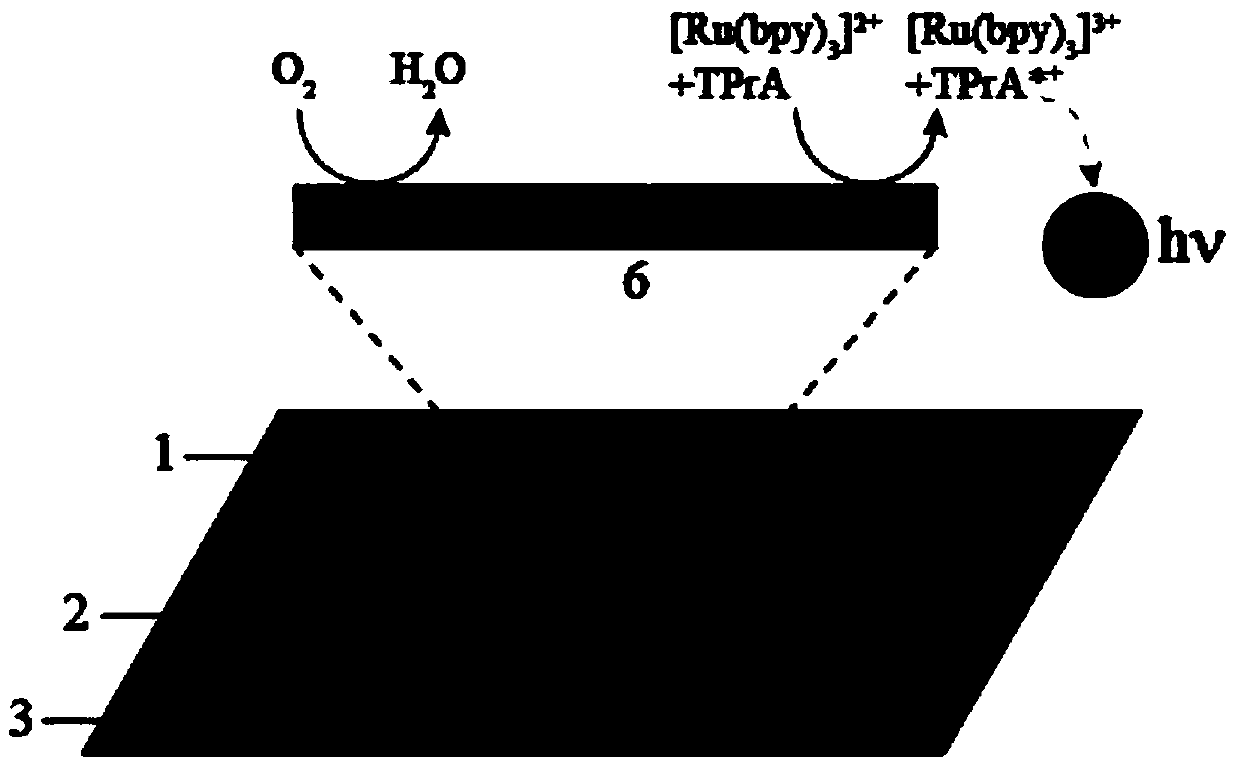

[0038] The paper-based microfluidic chip prepared in Example 1 is used for Ru(bpy) 3 2+ ECL system to detect TPrA, including the following steps:

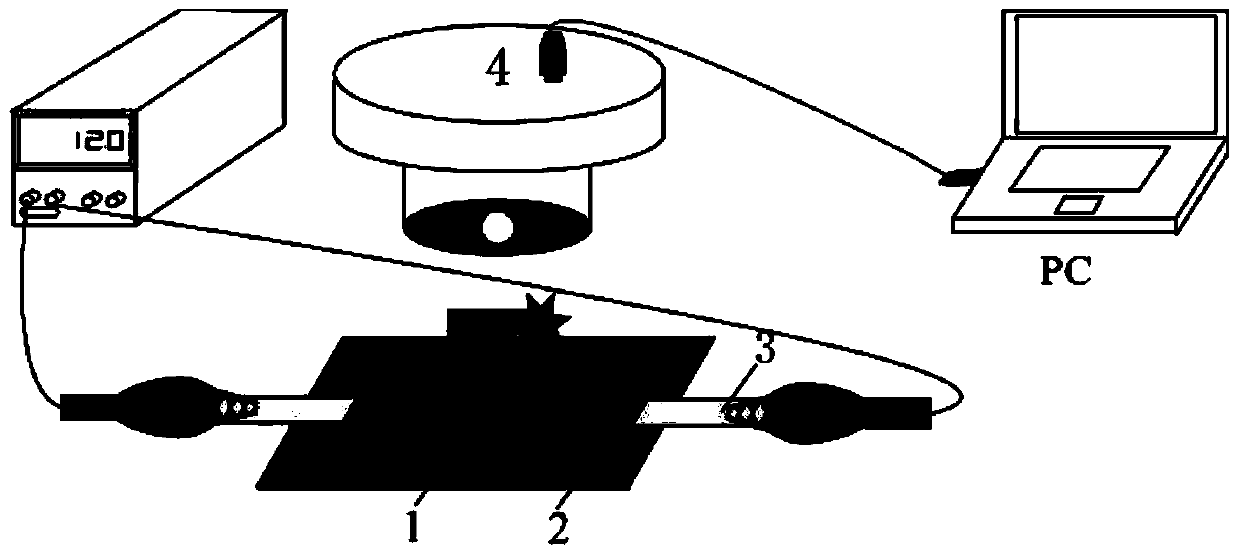

[0039] (1) Put the microfluidic chip in a dark box containing a CCD camera, such as image 3 As shown; Connect the driving electrodes to the power supply with conductive tape, and use clips to clamp both ends of the chip to make it suspended for detection;

[0040] (2) Use PBS buffer solution with a pH value of 6.9 to mix Ru(bpy) 3 2+ Prepare a solution with a concentration of 2 mM, and prepare TPrA with different concentrations, including 2000, 1000, 500, 200, 100, 50, and 20 μM, with PBS buffer. Before the experimental detection, the TPrA solution and Ru(bpy) 3 2+ The solutions were mixed at a volume ratio of 1:1 to obtain a solution containing Ru(bpy) 3 2+ and the mixed solution of TPrA;

[0041] (3) The pipette gun draws 15 μL of the prepared reaction solution (that is, contains Ru(bpy) 3 2+ and TPrA) were added dropwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com