Preparation method of lithium-sulphur battery electrode

A lithium-sulfur battery and electrode technology, which is applied in the field of preparation of lithium-sulfur battery electrodes, can solve the problems of limiting the practical use of lithium-sulfur batteries, reducing the energy density of electrodes, and unavoidable contact resistance, etc., to achieve the suppression of shuttle effect and the improvement of energy density , Improve the effect of mechanical properties and electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

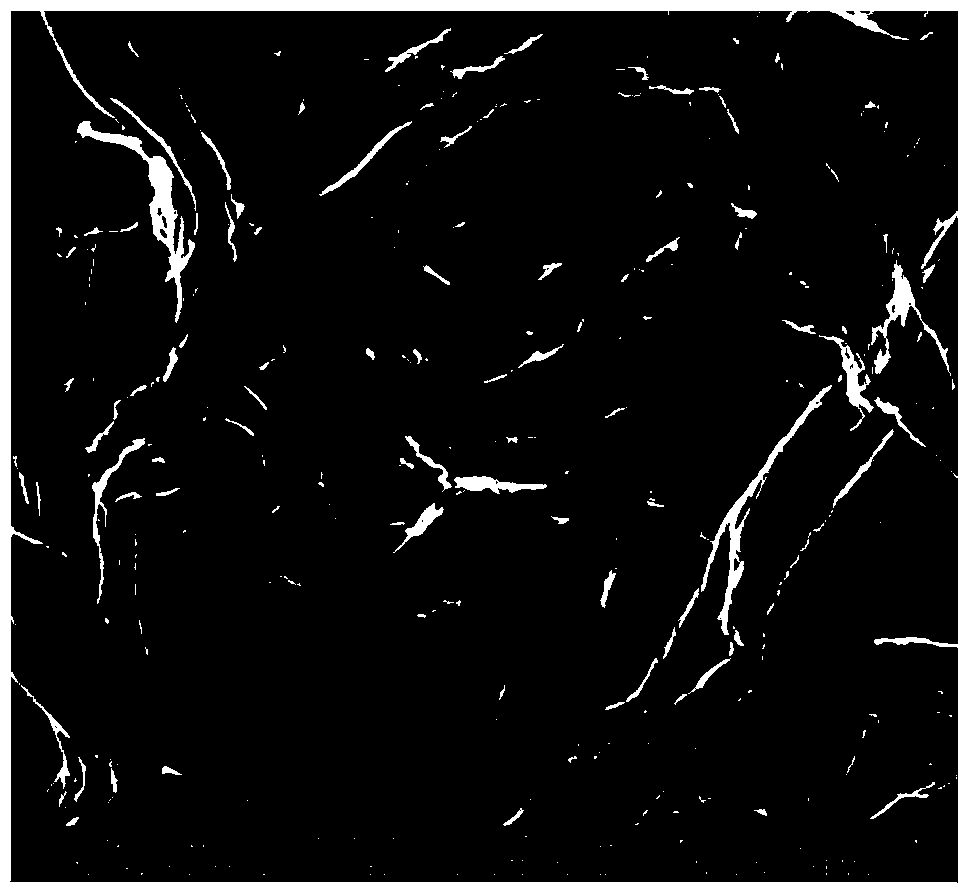

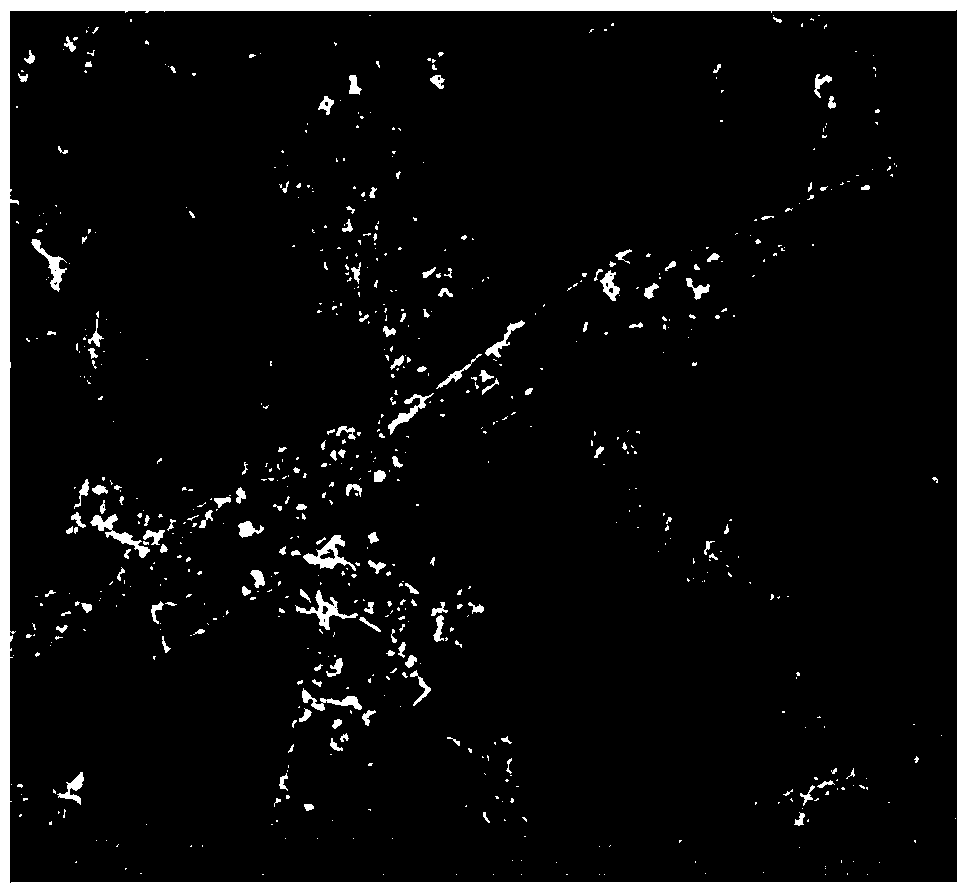

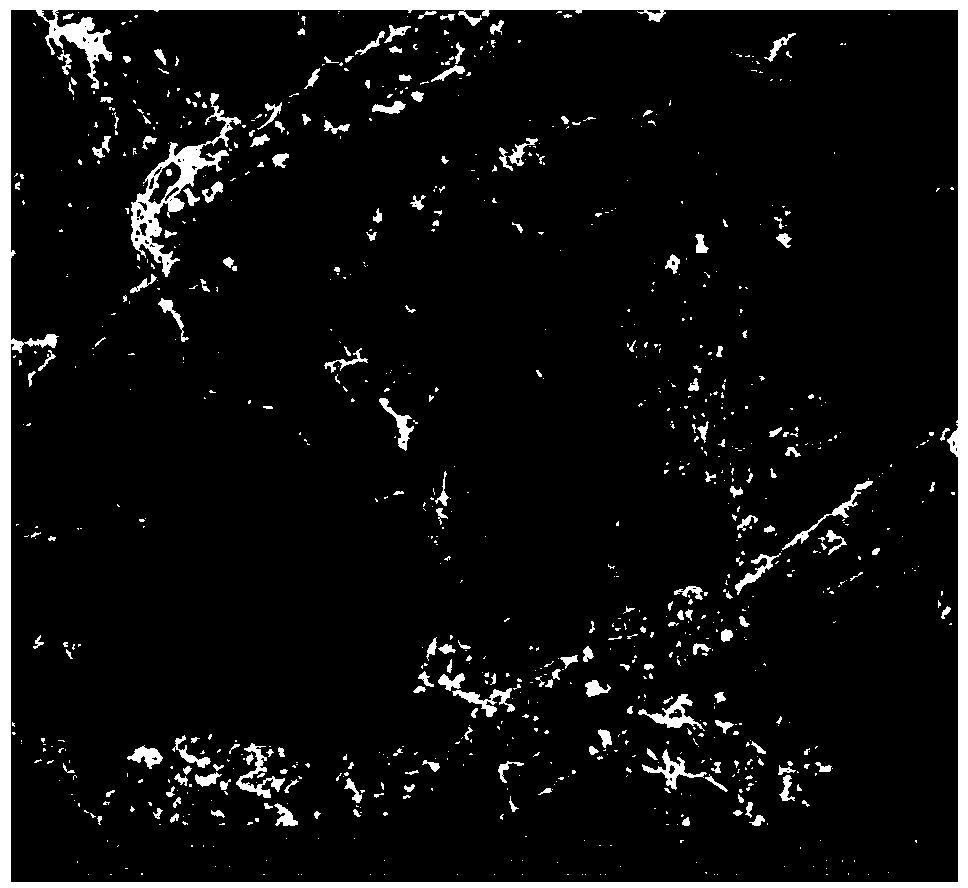

Image

Examples

Embodiment 1

[0034] A filter paper sheet with a thickness of 20 microns and a mass of 0.02 g was immersed in 0.5 mol / L n-butyl titanate solution for 3 hours, then taken out to dry at 100°C, and then placed in water for hydrolysis reaction to obtain nano-titanium dioxide supported on The composite body on the paper sheet; the obtained composite body is placed under a nitrogen protective atmosphere and heated to 800 ° C for carbonization for 5 hours to obtain a titanium dioxide (62wt%) composite current collector with a carbon fiber network structure as a self-supporting body; in the resulting carbon fiber network structure Add 5.0mL of 4.0mol / L sulfur-containing carbon disulfide solution to the surface of the self-supporting titanium dioxide composite current collector, first dry at 60°C in a drying oven to remove carbon disulfide, and then place it in a tube furnace under a nitrogen protective atmosphere and heat it up to 155°C for heat treatment After 10 hours, a lithium-sulfur battery ele...

Embodiment 2

[0041] Put a printing paper sheet with a thickness of 50 microns and a mass of 0.075 g into a 0.1 mol / L n-butyl titanate solution and soak it for 0.5 hours, take it out to dry at 60°C, and then put it in water for hydrolysis reaction to obtain nano-titanium dioxide loaded The composite body on the paper sheet; the obtained composite body is placed in an argon protective atmosphere and heated to 600 ° C for carbonization for 10 hours to obtain a titanium dioxide (25wt%) composite current collector with a carbon fiber network structure as a self-supporting body; Add 6.0mL of 0.5mol / L sulfur-containing carbon disulfide solution to the surface of the self-supporting titanium dioxide composite current collector, dry at 40°C in a drying oven to remove carbon disulfide, and then place the temperature in a tube furnace to 400°C under a nitrogen protective atmosphere. ℃ heat treatment for 8 hours to obtain a lithium-sulfur battery electrode with a sulfur mass content of 60%. The lithiu...

Embodiment 3

[0043] Put a piece of writing paper with a thickness of 10 microns and a mass of 0.01 g into a 2.0 mol / L n-butyl titanate solution and immerse it for 5 hours, take it out and dry it at 100°C, and then put it in water for hydrolysis reaction to obtain nano-titanium dioxide loaded Composite body on the paper sheet; Gained composite body is heated to 1000 ℃ under argon protective atmosphere and carries out carbonization 2 hours, obtains the titanium dioxide (70wt%) composite current collector with carbon fiber network structure as self-supporting body; Gained with carbon fiber The titanium dioxide composite current collector with a self-supporting network structure is soaked in a 2mol / L sulfur-containing carbon disulfide solution, dried in a drying oven at 50°C to remove carbon disulfide, and then placed in a tube furnace and heated to 150°C under a nitrogen protective atmosphere After heat treatment for 4 hours, a lithium-sulfur battery electrode with a sulfur mass content of 68%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com