Preparation method for low-viscosity methyl soyate

A technology of oil methyl ester and low viscosity, applied in the field of preparation of low viscosity soybean oil methyl ester, can solve the problems of poor offset printing adhesion, smearing, affecting printing quality and efficiency, etc., so as to reduce VOC emission and speed up drying speed. , good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

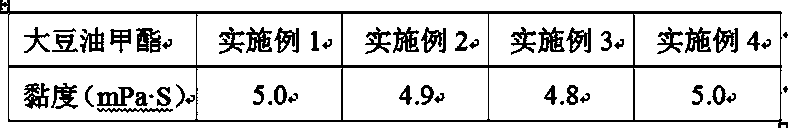

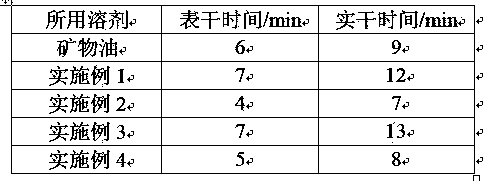

Embodiment 1

[0024] Add 96 grams of soybean oil and 16 grams of methanol in a 250mL three-necked bottle equipped with a condenser, start the stirring device, heat up, add 0.48 grams of catalyst solid super acid SO 4 2- / SnO 2 , heat up to 60°C, start timing, after reaching the required reaction time of 50 minutes, the reaction is over, cool to room temperature, add 4.8 grams of saturated saline to the product to wash until it is clear and transparent, then pass it into a high-speed centrifuge and centrifuge at a speed of 1000rpm 15min, then remove the lower glycerin layer, soap and the remaining superacid or superbasic water phases, and the collected upper liquid phase is soybean oil methyl ester.

Embodiment 2

[0026] Add 96 grams of soybean oil and 24 grams of methanol in a 250mL three-necked bottle equipped with a condenser, start the stirring device, heat up, add 1.92 grams of catalyst solid super acid SO 4 2- / SnO 2 , the temperature was raised to 70°C, and the timing was started, and the reaction ended after reaching the required reaction time of 70 minutes. Cool to room temperature, add 24 grams of saturated saline to the product and wash until it is clear and transparent, then pass it into a high-speed centrifuge and centrifuge at a speed of 3000rpm for 40min, then remove the lower glycerol layer, soap and the remaining water phase such as super acid or super alkali , the collected upper liquid phase is soybean oil methyl ester.

Embodiment 3

[0028] Add 96 grams of soybean oil and 19 grams of methyl alcohol in the 250mL three-necked flask equipped with a condenser, start the stirring device, heat up, add 1.2 grams of catalyst solid super base MgO-SnO 2 , the temperature was raised to 67°C, and the timing was started. After reaching the required reaction time of 60 minutes, the reaction ended. Cool to room temperature, add 13 grams of saturated saline to the product and wash until it is clear and transparent, then pass it into a high-speed centrifuge and centrifuge at a speed of 2000rpm for 30min, then remove the lower glycerin layer, soap and the remaining superacid or superbasic water phase , the collected upper liquid phase is soybean oil methyl ester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com