Method and device for reducing nitrogen oxides in smoke gas of industrial coal-fired boiler by biomass

A technology of industrial boilers and nitrogen oxides, which is applied in the direction of solid fuel combustion, combustion equipment, lighting and heating equipment, etc., can solve the problems of unfavorable biomass combustion and low flue gas temperature, and achieve enhanced rigidity and reduction zone mixing Conditions, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

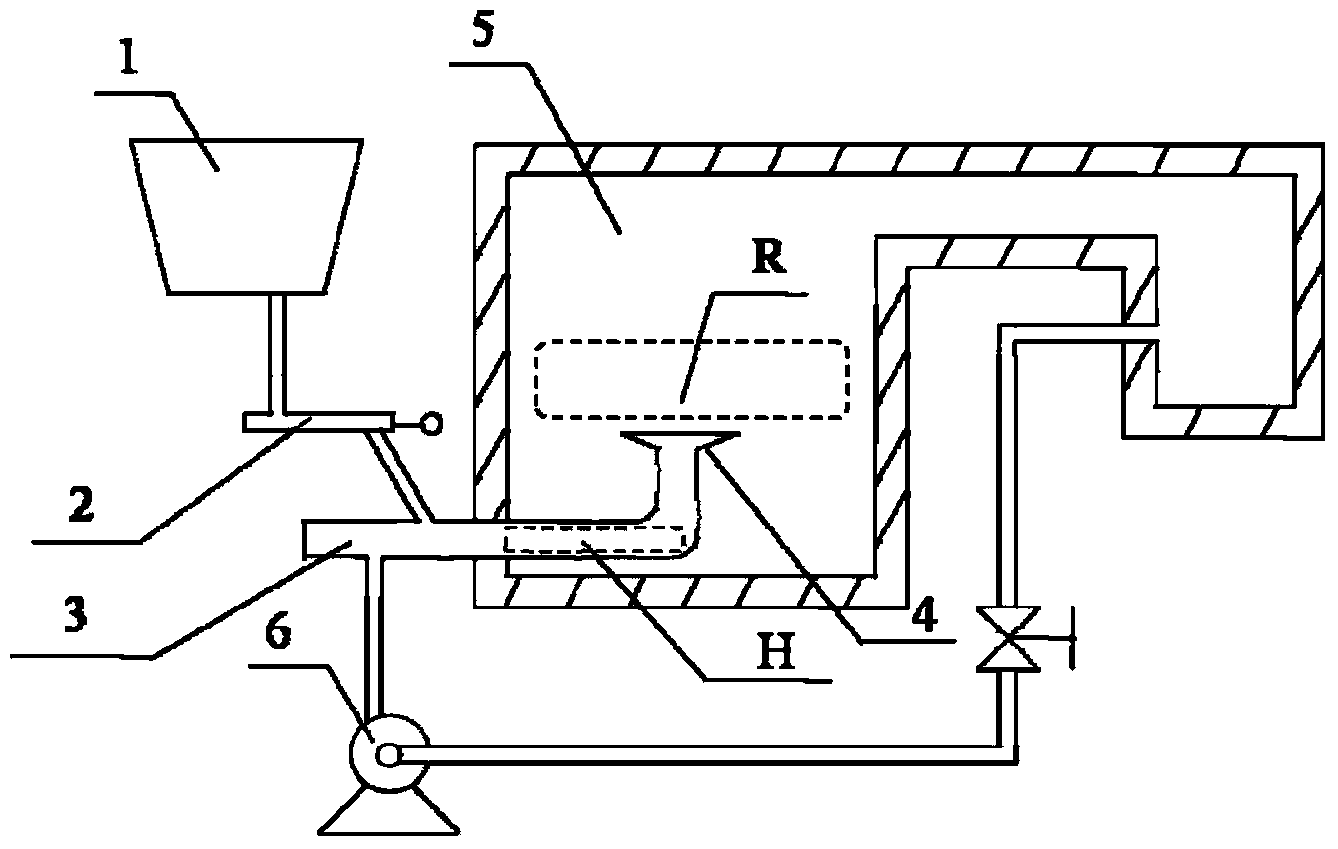

[0033] see figure 1 As shown, the common poplar sawdust in North China was selected as the biomass material, and a 2t / h coal-fired experimental boiler was selected for testing. Part of the hot flue gas from the tail flue of the coal-fired experimental boiler was used to transport the biomass particles through the conveying pipe 3. The pyrolysis section H is sprayed into the furnace to form the reduction zone R. The biomass particles undergo pyrolysis reaction in the pyrolysis section H, and active groups such as hydrocarbon groups and amino groups are precipitated.

[0034] The calorific value of biomass particles accounts for 1.2% of the total calorific value of the boiler. The temperature of the hot flue gas from the flue at the tail of the boiler is 110°C, and the amount of flue gas is 5% of the exhaust gas volume of the boiler. The excess air coefficient after carrying biomass particles is 0.65. The temperature of the pyrolysis section H is 950°C, and the residence time o...

Embodiment 2

[0038] The process conditions of this embodiment are roughly the same as those of Embodiment 1, wherein the temperature of the pyrolysis section H is 1050° C., and the temperature of the reduction zone R is 900° C., and the denitrification efficiency reaches 55% at this time.

Embodiment 3

[0040] The process conditions are roughly the same as in Example 1, wherein the temperature of the pyrolysis section H is 900° C., and the temperature of the reduction zone R is 700° C., and the denitrification efficiency reaches 38%.

[0041] In summary, the method and device of the present invention can effectively promote the same-phase reduction reaction between hydrocarbon groups, amino groups and other active groups and nitrogen oxides in boiler flue gas, and the residual coke after biomass pyrolysis and boiler smoke The heterogeneous reduction reaction between nitrogen oxides in the gas greatly reduces the concentration of nitrogen oxides in the flue gas of industrial boilers, and the denitrification rate reaches 30%-60%. The purpose of reducing pollution and protecting the environment can be achieved by using readily available biomass raw materials, and it is easy to modify existing boilers to meet environmental protection requirements. Therefore, this technology has ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com