Sow feed and production method thereof

A sow feed and breeding sow technology, applied in animal feed, animal feed, applications, etc., can solve the problems of drug residues, pregnancy and adverse effects of production, etc., and achieve simple processing, good lactation effect, and reduce chemical drugs The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

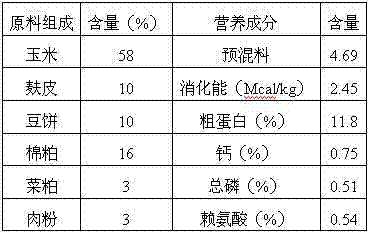

Examples

Embodiment 1

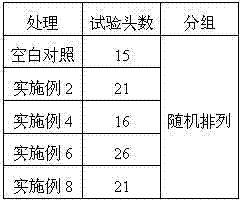

[0034] Example 1 Sow Feed Processing Formula

[0035] Adopt following formula to carry out the processing of sow feed of the present invention:

[0036]

[0037] The above formulas are all implemented in parts by weight.

Embodiment 2

[0038] Embodiment 2 sow feed production method (1)

[0039] (1) Pre-grind trace elements first, pass through 80-mesh sieve, then mix molasses and trace elements at 28°C according to the formula ratio, stir for 30 minutes, mix thoroughly, dehydrate, dry, crush, pass through 60-mesh sieve, and set aside . The composition of the trace element formula is: copper sulfate, zinc sulfate, manganese sulfate, ferrous sulfate, calcium iodate, magnesium sulfate and sodium selenite, the added molar ratio is: copper: zinc: manganese: iron: calcium: magnesium: selenium is 1:1:1:1:5:5:0.1.

[0040] (2) Sieve the sugarcane pith used for bagasse papermaking or wood-based panels, dry and crush through a 60-mesh sieve for later use.

[0041] (3) Dehydrate, dry, and crush peanut vines, pine needles, heartbroken grass, rice bran or wheat bran, and papaya leaves to 60 mesh respectively, and set aside.

[0042] (4) Pre-mix the trace elements processed in the above steps, molasses and saponin in ...

Embodiment 3

[0044] Embodiment 3 sow feed production method (2)

[0045] (1) Pre-grind trace elements and pass through 80-mesh sieve, then mix molasses and trace elements according to the formula ratio at 25°C for 20 minutes, mix thoroughly, dehydrate, dry, crush and pass through 80-mesh sieve, and set aside. Trace element formula ingredients are: copper chloride, zinc oxide, manganese glycinate, ferric citrate, calcium iodate, magnesium sulfate and sodium selenate added molar ratio: copper: zinc: manganese: iron: calcium: magnesium: selenium is 1.5 :1.5:3:2:7:10:0.3.

[0046] (2) Sieve the sugarcane pith used for bagasse papermaking or wood-based panels, dry and crush through an 80-mesh sieve for later use.

[0047] (3) Dehydrate, dry, and crush peanut vines, pine needles, heartbroken grass, rice bran or wheat bran, and papaya leaves to 80 mesh respectively, and set aside.

[0048] (4) Pre-mix the trace elements processed in the above steps, molasses and saponin in proportion for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com