Fully-mixed ration feed capable of reducing weaning stress of lamb

A technology of weaning stress and premixed feed, which is applied in the field of sheep feed, can solve the problems of not considering the interaction effect of feed raw materials, not being suitable for intensive and large-scale production, and the large change range of rumen pH value, so as to improve the sheep raising efficiency. Economic benefits, improvement of survival rate and breeding rate, and effect of reducing feed cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

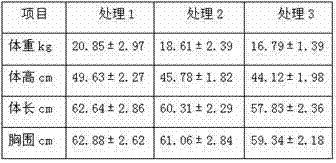

Examples

Embodiment 1

[0029] 36 parts of corn, 7 parts of soybean meal, 7 parts of wheat bran, 7 parts of silkworm excrement, 30 parts of milk replacer, 6 parts of yeast powder, 6 parts of straw, 10 parts of silage corn, 6 parts of green hay, 1 part of calcium powder, phosphoric acid 0.7 parts of calcium hydrogen and 1.5 parts of premixed feed.

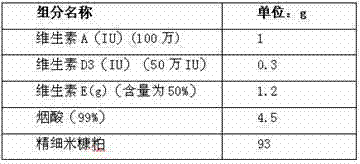

[0030] Based on the weight of the premixed feed itself, the premixed feed consists of the following components by weight: 45 parts of table salt, 40 parts of baking soda, 35 parts of compound trace elements, 35 parts of multivitamins, 20 parts of anhydrous saccharin sodium and over 30 parts of rumen methionine.

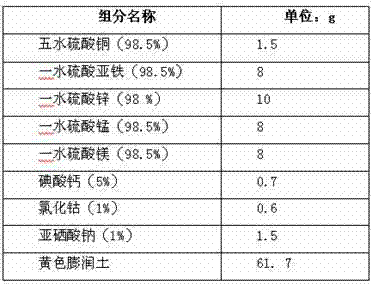

[0031] Calculated based on the weight of the composite trace element itself, the composite trace element is composed of the following raw materials in parts by weight: 30 parts of copper sulfate pentahydrate, 10 parts of ferrous sulfate monohydrate, 15 parts of zinc sulfate monohydrate, 12 parts of manganese sulfate monohydrate , 10 parts of magn...

Embodiment 2

[0040] 35 parts of corn, 5 parts of soybean meal, 5 parts of wheat bran, 5 parts of silkworm excrement, 20 parts of milk substitute powder, 2 parts of yeast powder, 2 parts of bean straw, 5 parts of silage corn, 3 parts of green hay, 0.5 parts of calcium powder, phosphoric acid 0.4 parts of calcium hydrogen and 1 part of premixed feed.

[0041] Calculated based on the weight of the premixed feed itself, the premixed feed consists of the following components by weight: 40 parts of table salt, 25 parts of baking soda, 20 parts of compound trace elements, 20 parts of multivitamins, 10 parts of anhydrous saccharin sodium and over Rumen methionine 10 parts.

[0042] Calculated based on the weight of the composite trace element itself, the composite trace element is composed of the following raw materials in parts by weight: 10 parts of copper sulfate pentahydrate, 8 parts of ferrous sulfate monohydrate, 10 parts of zinc sulfate monohydrate, and 8 parts of manganese sulfate monohydr...

Embodiment 3

[0046] 40 parts of corn, 10 parts of soybean meal, 10 parts of wheat bran, 10 parts of silkworm excrement, 35 parts of milk replacer powder, 8 parts of yeast powder, 8 parts of straw, 20 parts of silage corn, 8 parts of green hay, 1.5 parts of calcium powder, phosphoric acid 1 part of calcium hydrogen and 3 parts of premixed feed.

[0047] Calculated based on the weight of the premixed feed itself, the premixed feed consists of the following components by weight: 50 parts of table salt, 50 parts of baking soda, 50 parts of compound trace elements, 50 parts of multivitamins, 30 parts of anhydrous saccharin sodium and over 50 parts of rumen methionine.

[0048] Calculated based on the weight of the composite trace element itself, the composite trace element is composed of the following raw materials in parts by weight: 50 parts of copper sulfate pentahydrate, 15 parts of ferrous sulfate monohydrate, 18 parts of zinc sulfate monohydrate, 15 parts of manganese sulfate monohydrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com