Method for preparing metal organic framework-graphene oxide composite material

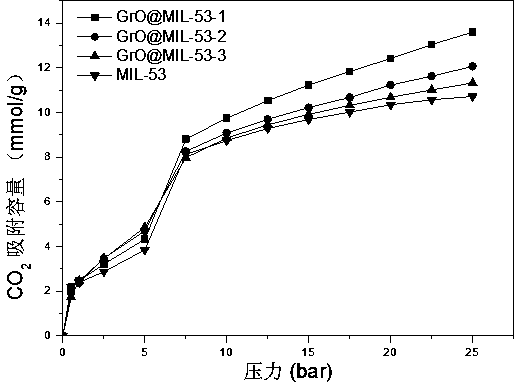

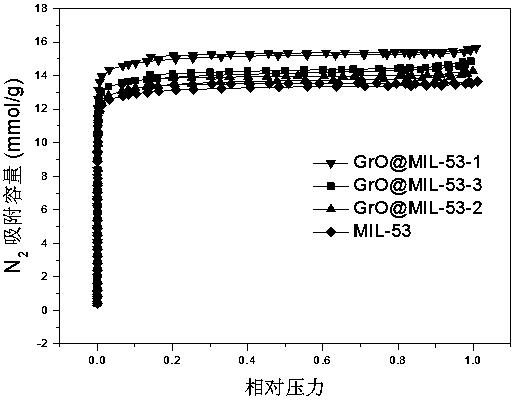

A metal-organic framework and composite material technology, applied in the field of composite material preparation, can solve problems such as low atomic density, and achieve the effects of increasing atomic density, improving pore volume, and improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

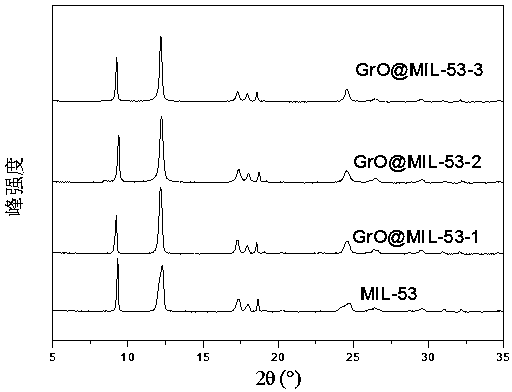

[0027] Add 2 g of graphite powder with a particle size of 60 μm to 4 g of NaNO 3 and 200mL concentrated sulfuric acid mixture, fully stirred in an ice bath, while slowly adding 20g KMnO 4 . Then the ice bath was removed, and after stirring for 48 hours, 1120 mL of deionized water at 60°C and 80 mL of H 2 o 2 , filtered, washed with water to remove excess acid, centrifuged, and spray-dried to obtain GO as a solid powder. According to GrO and Cr(NO 3 ) 3 9H 2The mass ratio of O was 1:100 to configure the reaction solution, and 0.02 g GO was dispersed in 25 mL deionized water for 180 min sonication to obtain the GrO aqueous solution. Add 2g Cr(NO 3 ) 3 9H 2 O, 1.66g H 2 BDC and 0.2mL HF were reacted at 230°C for 62 hours to obtain the GrOMIL-53 composite. Finally, the obtained material was rinsed with DMF for 3 times, then soaked for 24 hours, replaced with DMF every 12 hours, dried, and then kept at 250°C for 12 hours, then activated under vacuum at 130°C for 12 hours...

Embodiment 2

[0029] Add 4 g of graphite powder with a particle size of 30 μm to 4 g of NaNO 3 and 200mL concentrated sulfuric acid mixture, fully stirred in an ice bath, while slowly adding 24g KMNO 4 . Then remove the ice bath, continue to stir for 12 hours, add 1120 mL of 70 ° C deionized water, and finally add 80 mL of H 2 o 2 , filtered, washed with water to remove excess acid, centrifuged, and spray-dried to obtain solid powder GO. According to GrO and Cr(NO 3 ) 3 9H 2 The mass ratio of O was 5:100 to configure the reaction solution, and 0.2 g GO was dispersed in 25 mL deionized water for 120 min sonication to obtain the GrO aqueous solution. Add 4g Cr(NO 3 ) 3 9H 2 O, 1.66g H 2 BDC and 0.2mL HF were reacted at 220°C for 67 hours to obtain the GrOMIL-53 composite. Finally, the obtained material was rinsed with DMF for 5 times, then soaked for 48 hours, DMF was replaced every 18 hours, dried, then kept at 280°C for 18 hours, and vacuum activated at 150°C for 12 hours, the ob...

Embodiment 3

[0031] Add 8 g of graphite powder with a particle size of 20 μm to 4 g of NaNO 3 and 200mL concentrated sulfuric acid mixture, fully stirred in an ice bath, while slowly adding 16gKMNO 4 . Then the ice bath was removed, and after stirring for 24 hours, 1120 mL of 80°C deionized water and 80 mL of H 2 o 2 , filtered, washed with water to remove excess acid, centrifuged, and spray-dried to obtain solid powder GO. According to GrO and Cr(NO 3 ) 3 9H 2 The mass ratio of O was 10:100 to configure the reaction solution, and 0.05 g GO was dispersed in 25 mL deionized water for 60 min of power ultrasonic treatment to obtain the GrO aqueous solution. Add 0.5g Cr(NO 3 ) 3 9H 2 O, 1.66g H 2 BDC and 0.2mL HF were reacted at 210°C for 72 hours to obtain the GrOMIL-53 composite. Finally, the obtained material is rinsed twice with DMF, then soaked for 72 hours, replaced with DMF every 24 hours, dried, and then kept at 300°C for 12 hours, and then vacuum activated at 180°C for 8 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com