A water molecule cluster cutting reaction device

A technology of reaction device and water molecule, which is applied in the field of water molecule cluster cutting reaction device, can solve the problems of incapable of large-scale industrial production, low water content of small molecular clusters, and immature process, etc., to achieve reduced emulsification ability, strong penetration, The effect of endocrine regulation auxiliary improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

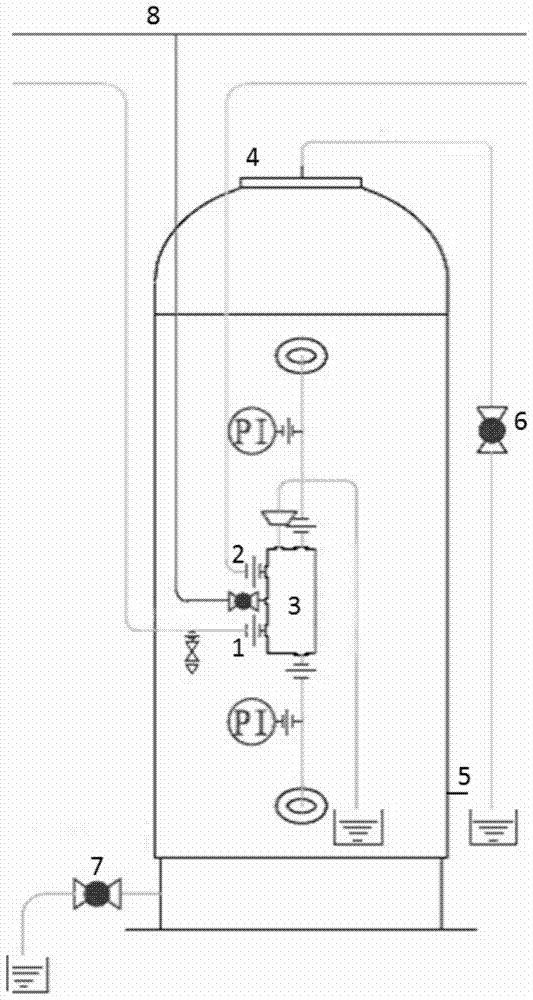

[0030] figure 1 It is a schematic diagram of the structure of the water molecule cutting reaction device, which includes a water inlet 1, a water outlet 2, a valve system 3, a filling port 4, a discharge port 5, an exhaust (water) port 6, an emptying port 7, and a CIP pipe Road 8. Wherein the water inlet 1, the water outlet 2, and the valve system 3 are located outside the side wall of the tank body of the device. The following illustrates the installation of the water molecule cutting reactor equipment:

[0031] 1. Equipment material and installation conditions

[0032] 1) The equipment is all made of 304 food grade stainless steel or 306 food grade stainless steel.

[0033] 2) Make sure the system is placed on a solid, level foundation, preferably concrete.

[0034] 3) The system should be located as close to the drain as possible.

[0035] 4) The sewer system shall be able to handle the backwash flow of the unit for up to 20 minutes.

[0036] 5) The ground should be s...

Embodiment 2

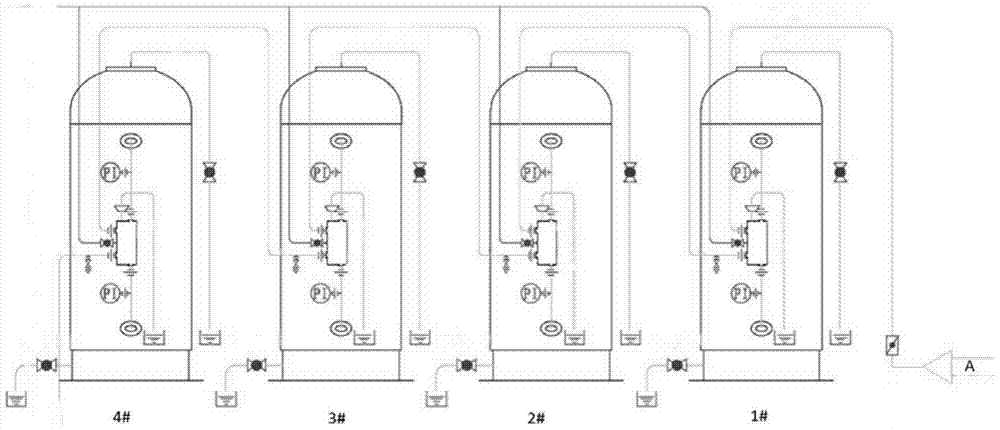

[0069] In this embodiment, four water molecule cutting reactors described in Embodiment 1 are connected to form a multi-stage treatment system, see figure 2 . The following describes how to install the water molecule cutting reactor equipment:

[0070] 1. Equipment material and installation conditions: see Embodiment 1, this embodiment is the same as it.

[0071] 2. Pipeline connection

[0072] Refer to Example 1 for the pipeline connection of a single water molecule cutting reactor, and this example is the same as it. In this embodiment, four water molecule cutting reactor units are used. In order to ensure uniform water distribution, each unit should be provided with exactly the same pipeline layout between the water inlet main pipe and the valve body, and between the valve body and the water outlet main pipe.

[0073] 3. Installation of the valve: refer to Embodiment 1, this embodiment is the same as it.

[0074] 4. Filling and unloading of composite materials: see Exa...

Embodiment 3

[0087] In this embodiment, two sets of multi-stage treatment devices in Embodiment 2 are used, that is, eight water molecule cutting reactors described in Embodiment 1 are connected. The following describes how to install the water molecule cutting reactor equipment:

[0088] 1. Equipment material and installation conditions: see Embodiment 1, this embodiment is the same as it.

[0089] 2. Pipeline connection: Refer to Example 1 for the pipeline connection of a single water molecule cutting reactor, and this embodiment is the same as it.

[0090] 3. Installation of the valve: refer to Embodiment 1, this embodiment is the same as it.

[0091] 4. Filling and unloading of composite materials: see Example 1, this example is the same as it.

[0092] 5. Connection of two sets of unit equipment, A and B

[0093] ① In order to ensure uniform water distribution, the four individual units in a set of unit equipment should have exactly the same pipeline layout between the water inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com