A device and method for treating petrochemical wastewater by microaerobic hydrolysis acidification-a/o biofilm method

A technology for hydrolyzing acidification and petrochemical wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. environment and other problems, to achieve the effect of improving processing capacity and operation stability, inhibiting sulfate reduction reaction, and increasing biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

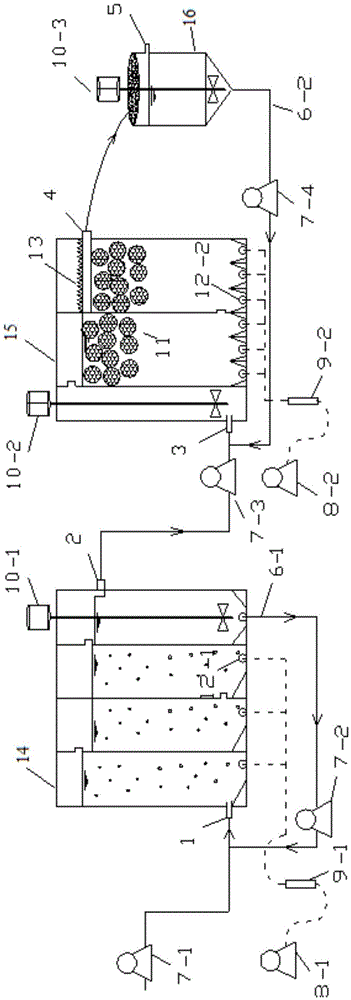

[0028] A device for treating petrochemical wastewater by microaerobic hydrolytic acidification-A / O biofilm method, which is composed of a hydrolytic acidification tank, an A / O biofilm reactor and a secondary sedimentation tank connected in sequence; an aeration tube is arranged at the bottom of the hydrolysis acidification tank , by controlling the amount of aeration to make it in the state of microaerobic hydrolysis and acidification; the O section of the A / O biofilm reactor is filled with biological fillers, and the volume filling rate is 30%.

[0029] The biological filler is a porous plastic ball carrier filled with polyurethane foam; each porous plastic ball is filled with four polyurethane foams of 1 cm square.

[0030] A sedimentation tank is provided at the end of the hydrolytic acidification tank for sludge reflux.

[0031] A sludge return pipe is set between the secondary settling tank and section A of the A / O biofilm reactor, and the sludge from the secondary settli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com