Method for producing dipropylene glycol butyl ether and tripropylene glycol butyl ether

A technology of tripropylene glycol butyl ether and dipropylene glycol butyl ether, which is applied in the field of clean production of organic solvents and can solve problems such as dangerous accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

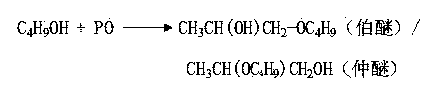

Method used

Image

Examples

Embodiment

[0055] A kind of method of producing dipropylene glycol butyl ether and tripropylene glycol butyl ether, concrete steps are as follows:

[0056] (1) First use a Karl Fischer moisture meter to measure the mass fraction of water in a certain batch of propylene glycol butyl ether extracted as a raw material, which is 0.05%; use the volumetric method of acid-base titration to measure the methanol in the tower liquid The massfraction of sodium is 2.50%; Then use FFAP strong polarity capillary chromatographic column to analyze the area percent of the component that can be detected by gas chromatography in the tower bottom liquid on the gas chromatograph, multiplied by (1-the massfraction of water-methanol The mass fraction of sodium) after such a coefficient, the mass fraction of the components that can be detected by gas chromatography in this batch of tower bottom liquid is obtained as:

[0057] Propylene Glycol Butyl Ether 0.45%

[0058] 2-Butoxy-1-propanol 23.63%

[0059] Dipr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com