Anti-termite inorganic flake waterborne epoxy resin coating

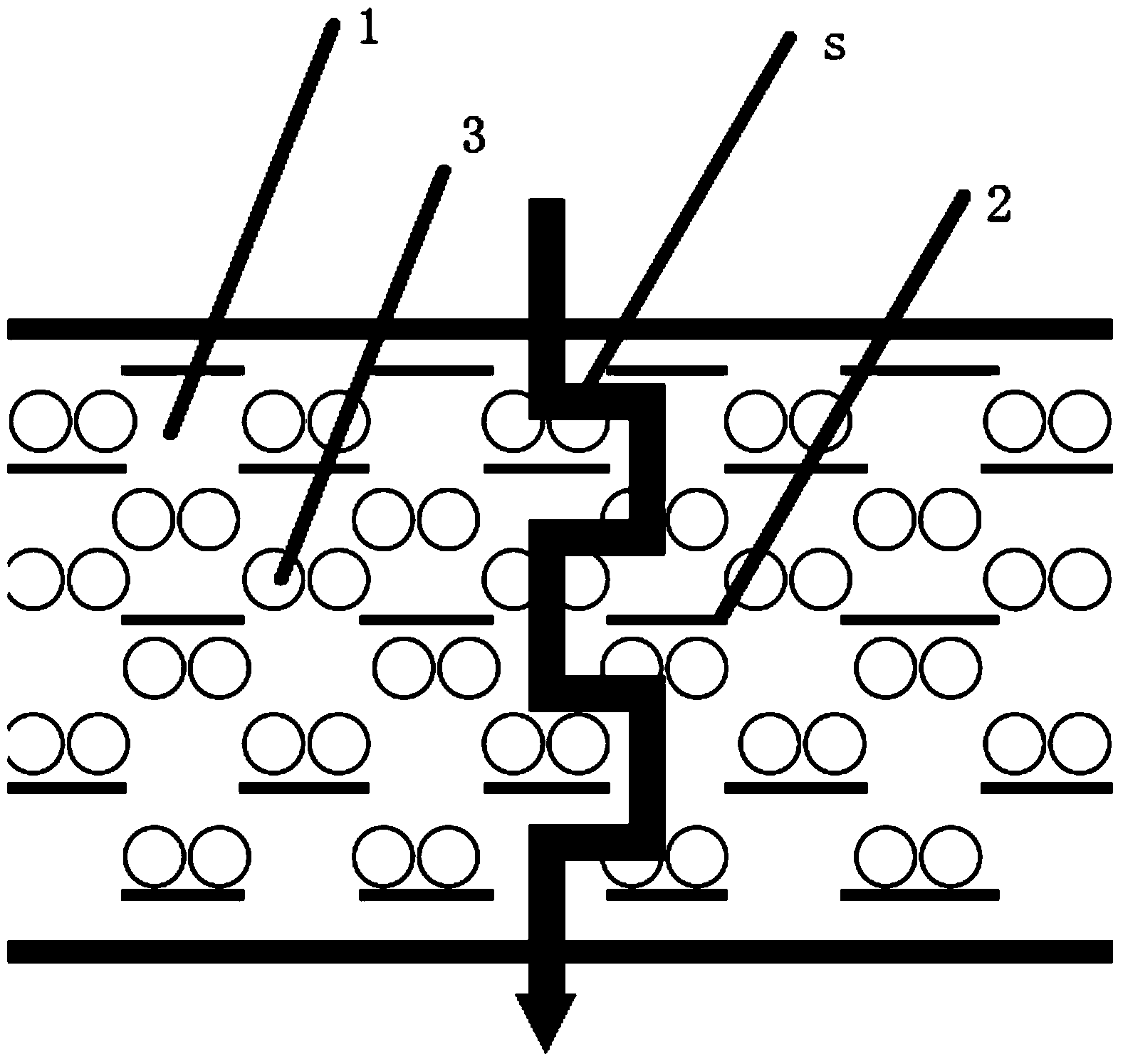

A water-based epoxy resin and anti-termite technology, applied in the field of coatings, can solve the problems of no moisture-proof effect and no moisture-proof effect, and achieve the effects of good termite resistance, low shrinkage, and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The anti-termite inorganic flake waterborne epoxy resin coating in the present embodiment comprises A component and B component, wherein:

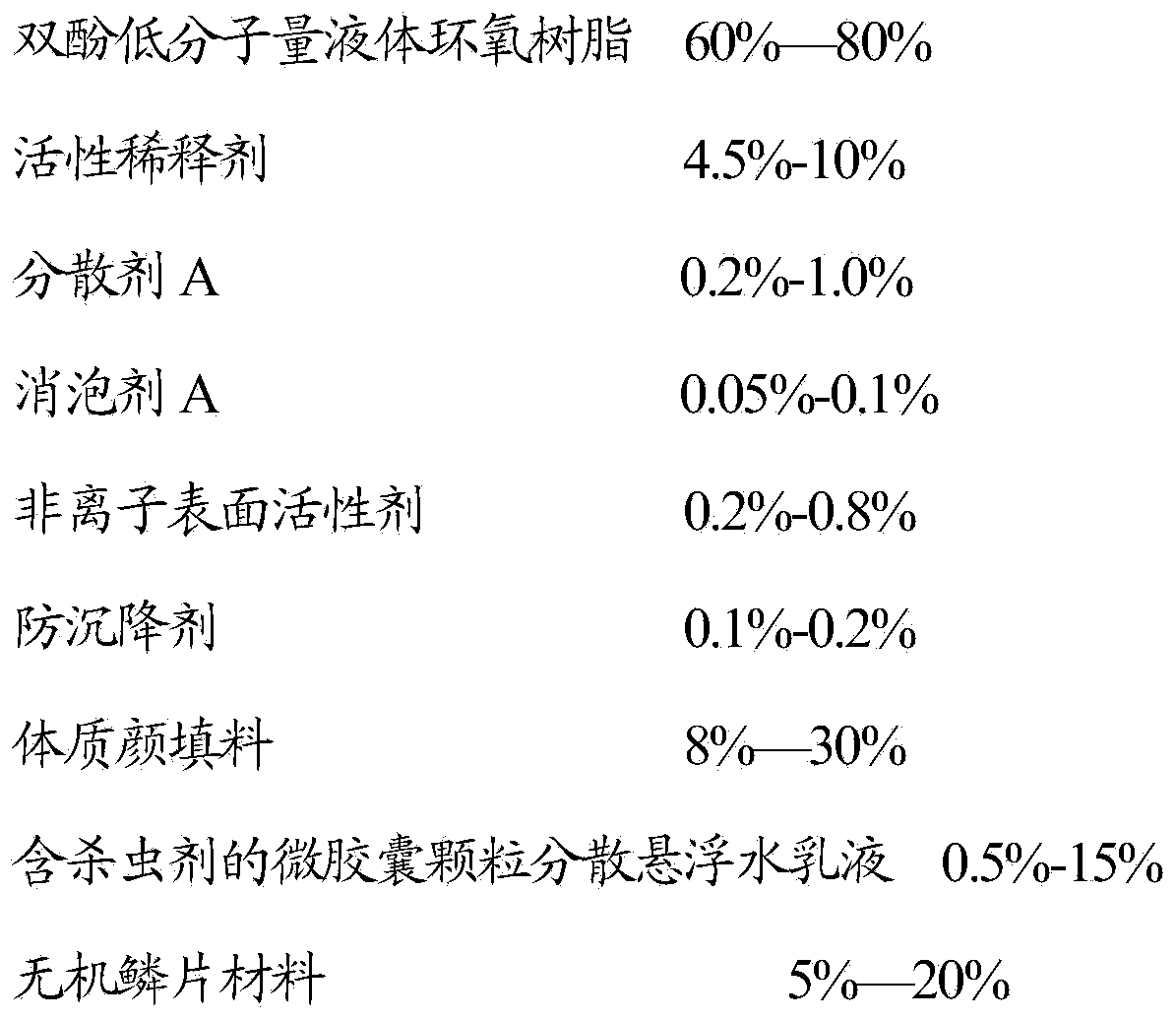

[0059] Component A comprises the following raw materials in percentage by weight:

[0060]

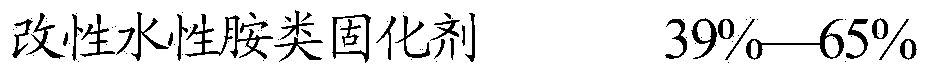

[0061] Component B includes raw materials in the following weight percentages:

[0062]

[0063] In this embodiment, the capsule inner core of the microcapsules is activated carbon porous particles, which are used as carrier materials for fully adsorbing insecticides.

[0064] The wall material of the microcapsules is prepared from polymethyl polyphenylisocyanate and hexamethylenetetramine at a weight ratio of 1:2.

[0065] The insecticide is prepared from pyrethroid and fenitrothion at a weight ratio of 1:3.

Embodiment 2

[0067] The anti-termite inorganic flake waterborne epoxy resin coating in the present embodiment comprises A component and B component, wherein:

[0068] Component A comprises the following raw materials in percentage by weight:

[0069]

[0070] Component B includes raw materials in the following weight percentages:

[0071]

[0072] In this embodiment, the capsule inner core of the microcapsules is bamboo charcoal porous particles, which are used as carrier materials for fully adsorbing insecticides.

[0073] The wall material of the microcapsules is prepared from polymethyl polyphenylisocyanate and hexamethylenetetramine at a weight ratio of 1:3.

[0074] The insecticide is prepared from pyrethroid and fenitrothion at a weight ratio of 1:5.

Embodiment 3

[0076] The anti-termite inorganic flake waterborne epoxy resin coating in the present embodiment comprises A component and B component, wherein:

[0077] Component A comprises the following raw materials in percentage by weight:

[0078]

[0079] Component B includes raw materials in the following weight percentages:

[0080]

[0081] In this embodiment, the capsule inner core of the microcapsules is activated carbon porous particles, which are used as carrier materials for fully adsorbing insecticides.

[0082] The wall material of the microcapsules is prepared from polymethyl polyphenylisocyanate and hexamethylenetetramine at a weight ratio of 1:1.

[0083] The insecticide is prepared from pyrethroid and fenitrothion at a weight ratio of 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com