Multifunctional type high-temperature-resistant composite well control fluid and preparation method and applications thereof

A multi-functional, well-killing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of oil and gas layer damage, high temperature resistance, corrosion side effects, etc., and achieve low oil layer damage and filtration loss. Small, good effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

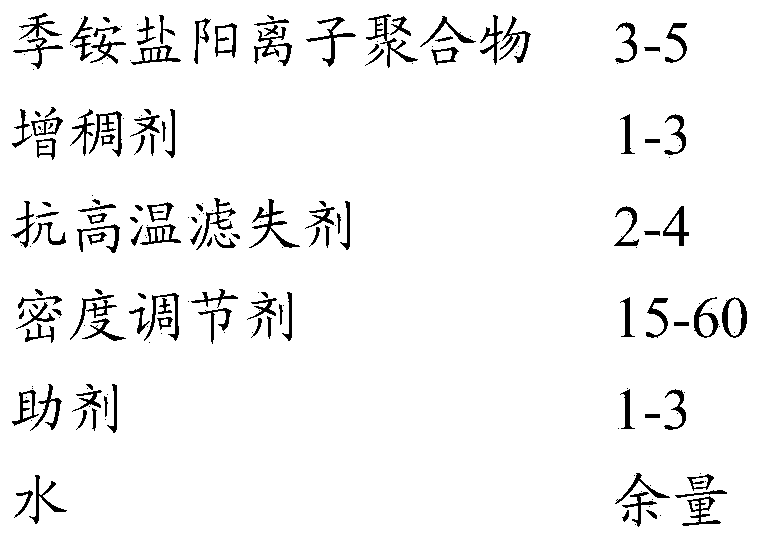

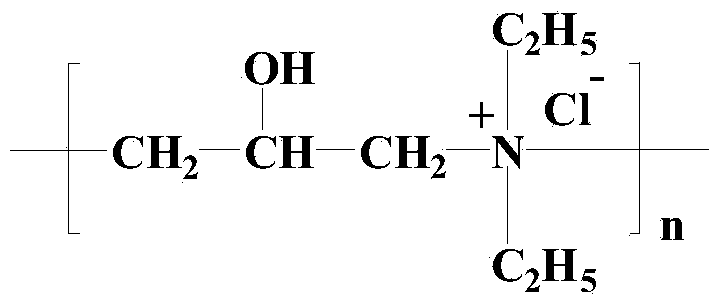

[0055] Preparation Example 1: Preparation of Quaternary Ammonium Salt Cationic Polymer

[0056] Add epichlorohydrin dropwise in diethylamine, wherein the mol ratio of diethylamine and epichlorohydrin is 1.1:1; add ammonium persulfate-sodium bisulfite initiator system again after dropwise addition, wherein over The molar ratio of ammonium sulfate to sodium bisulfite is 1.5:1, and the ratio of the total molar amount of the two to the molar amount of epichlorohydrin is 0.06:1; the reaction temperature is controlled between 15-20°C, and the After adding the reagent, raise the temperature to 40°C and react for 40 minutes; after the reaction, filter the resulting reaction mixture, then wash it with ethyl acetate and n-hexane in sequence, and dry it in a vacuum oven at 70-80°C for 1-2 Hour, obtain light yellow viscous liquid, be described quaternary ammonium salt cationic polymer, name Q1, after measuring its number average molecular weight is 30000-35000.

preparation example 2

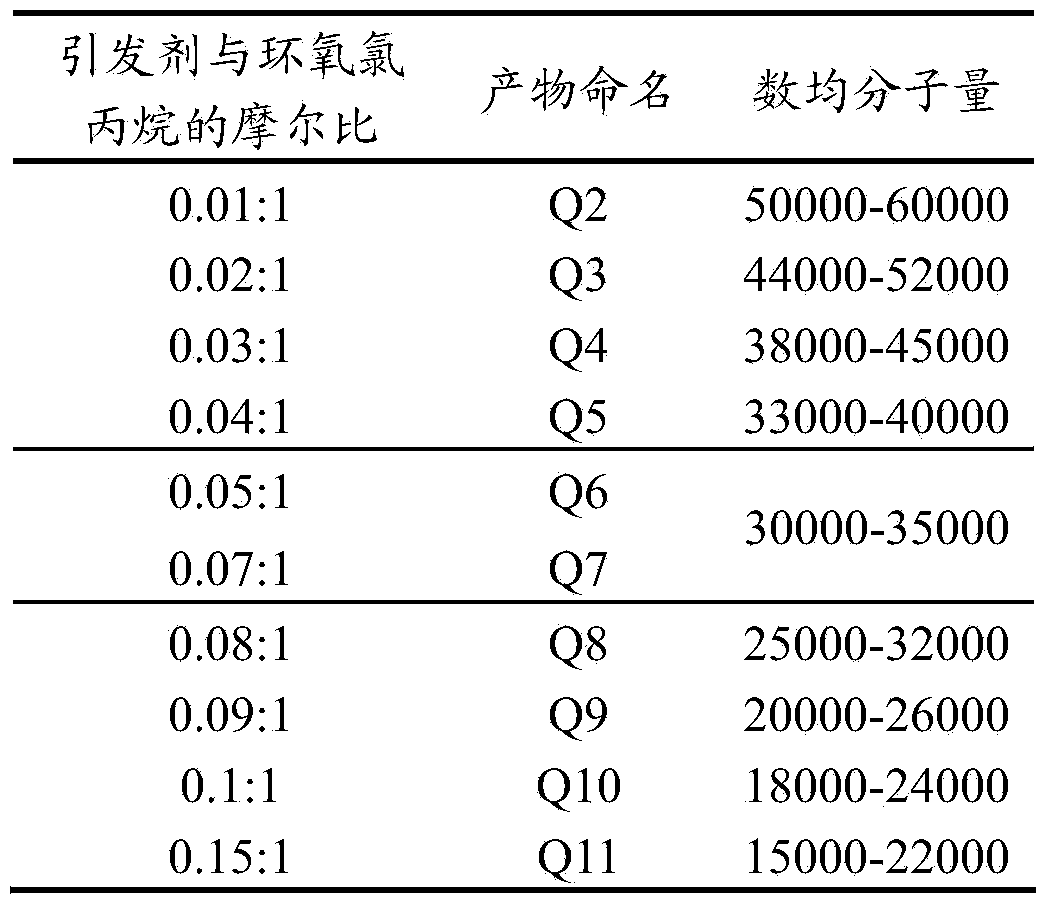

[0057] Preparation Example 2: Investigation of Initiator Consumption During Preparation of Quaternary Ammonium Salt Cationic Polymer

[0058] Add epichlorohydrin dropwise in diethylamine, wherein the mol ratio of diethylamine and epichlorohydrin is 1.2:1; Add ammonium persulfate-sodium bisulfite initiator system again after dropwise addition, wherein over The molar ratio of ammonium sulfate to sodium bisulfite is 1.5:1, and the ratio of the total molar amount of the two to the molar amount of epichlorohydrin is shown in Table 1 below; the reaction temperature is controlled between 15-20°C, After the initiator was added, the temperature was raised to 40°C for 40 minutes; after the reaction, the resulting reaction mixture was filtered, then washed with ethyl acetate and n-hexane in sequence, and dried in a vacuum oven at 70-80°C for 1 -2 hours, to obtain a light yellow viscous liquid, namely to obtain the quaternary ammonium salt cationic polymer, its designation and number aver...

preparation example 3

[0062] Preparation Example 3: Investigation of Temperature During Preparation of Quaternary Ammonium Salt Cationic Polymer

[0063] Add epichlorohydrin dropwise in diethylamine, wherein the mol ratio of diethylamine and epichlorohydrin is 1.1:1; add ammonium persulfate-sodium bisulfite initiator system again after dropwise addition, wherein over The molar ratio of ammonium sulfate to sodium bisulfite is 1.5:1, and the ratio of the total molar amount of the two to the molar amount of epichlorohydrin is 0.06:1; the reaction temperature is controlled between 15-20°C, and the After the addition of the reagent, the temperature was raised to the temperature shown in Table 2 below and reacted for 40 minutes; after the reaction, the resulting reaction mixture was filtered, then washed with ethyl acetate and n-hexane in sequence, placed in a vacuum oven at 70- Dry at 80°C for 1-2 hours to obtain a light yellow viscous liquid, that is, to obtain a quaternary ammonium salt cationic polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com