Preparation method of liquid yoghurt starter, liquid yoghurt starter prepared with preparation method and application of liquid yoghurt starter

A yogurt starter and liquid technology, which is applied in the preparation of liquid yogurt starter and the preparation of premixed liquid yogurt starter, achieves the effects of reducing production cost, improving equipment utilization rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

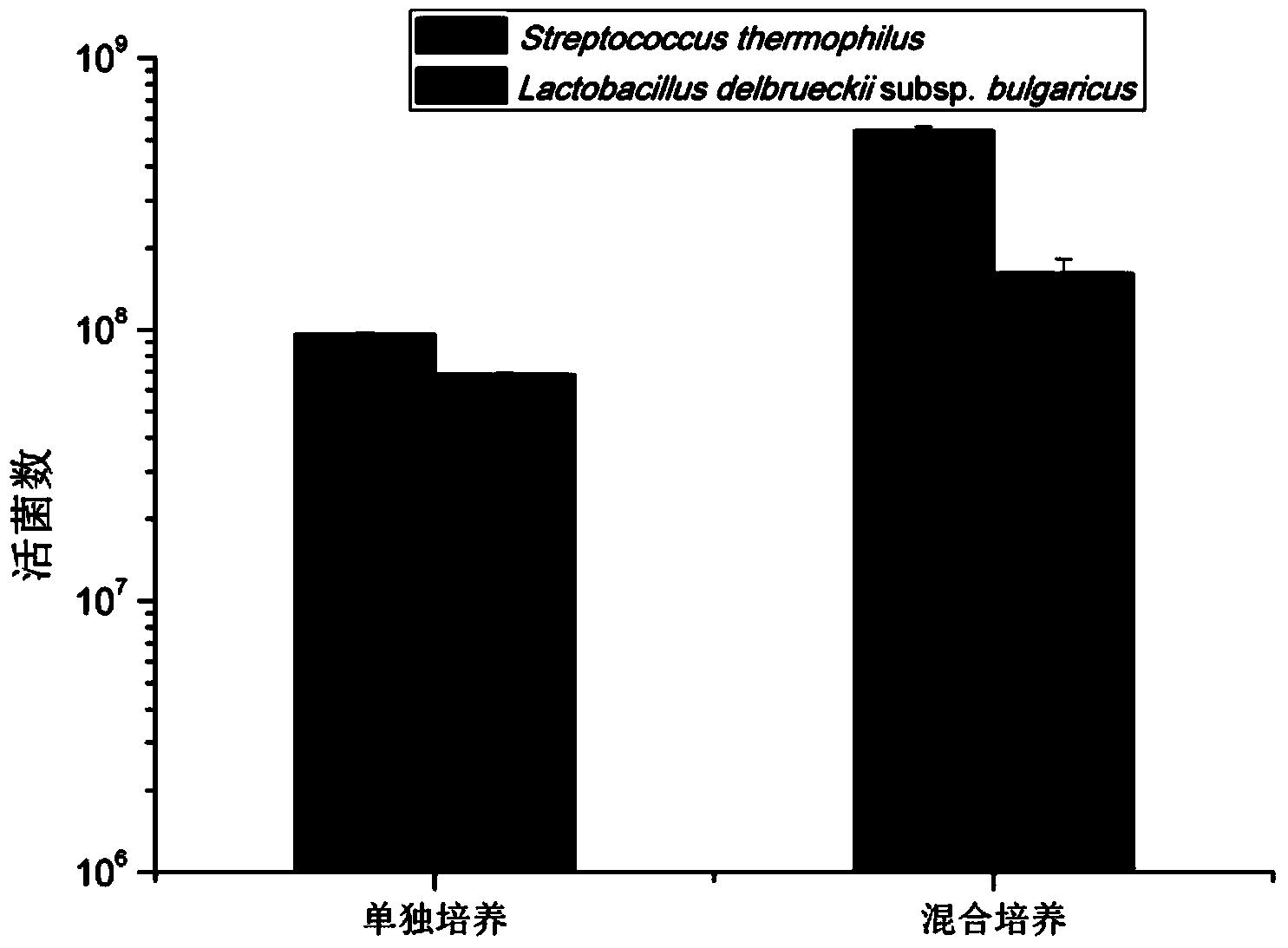

[0025] Embodiment 1: the preparation of premixed yogurt starter

[0026] (1) Streptococcus thermophilus CGMCC NO.9781 in the early stage of the stable growth period was inoculated into LM17 medium, and cultured statically at 42°C for 12 hours;

[0027] (2) Lactobacillus delbrueckii subsp. bulgaricus ATCC11842 in the early stage of the stable growth period was inoculated into the MRS medium, and cultured statically at 37° C. for 12 hours;

[0028] (3) Inoculate the Streptococcus thermophilus CGMCC NO.9781 bacterial solution prepared in step (1) into RY medium according to the ratio of 4% by volume, and culture it statically at 42° C. for 6 hours;

[0029] (4) Add the bacterium solution of Lactobacillus delbrueckii subsp. bulgaricus ATCC11842 prepared in step (2) to the culture of step (3) according to the ratio of 2% by volume, and culture it statically at 42° C. for 10 hours, That is, a premixed liquid yogurt starter composed of Lactobacillus delbrueckii subspecies bulgaricus...

Embodiment 2

[0035] Embodiment 2: the preparation of premixed yogurt starter

[0036] (1) Streptococcus thermophilus CGMCC NO.9781 in the early stage of the stable growth period was inoculated into LM17 medium, and cultured statically at 42°C for 12 hours;

[0037] (2) Lactobacillus delbrueckii subsp. bulgaricus ATCC11842 in the early stage of the stable growth period was inoculated into the MRS medium, and cultured statically at 37° C. for 12 hours;

[0038] (3) Inoculate the Streptococcus thermophilus CGMCC NO.9781 bacterial solution prepared in step (1) in the RY medium at a ratio of 6% by volume, and culture it statically at 42°C for 4 hours;

[0039] (4) Add the bacterium solution of Lactobacillus delbrueckii subsp. bulgaricus ATCC11842 prepared in step (2) to the culture of step (3) according to the ratio of 2% by volume, and culture it statically at 42° C. for 12 hours, That is, a premixed liquid yogurt starter composed of Lactobacillus delbrueckii subspecies bulgaricus and Strepto...

Embodiment 3

[0045] Embodiment 3: the preparation of premixed yogurt starter

[0046] (1) Streptococcus thermophilus in the early stage of stable growth phase was inoculated into LM17 medium by conventional methods, and cultured statically at 43° C. for 10 hours, and set aside;

[0047] (2) Inoculate Lactobacillus delbrueckii subsp. bulgaricus subsp. bulgaricus in the early stage of the stable growth period into the MRS medium by conventional method, and culture it statically at 38°C for 10 hours, and set aside;

[0048] (3) Inoculate the Streptococcus thermophilus bacterial liquid prepared in step (1) in the RY medium according to the ratio of 5% by volume, and culture at 42° C. for 5 hours;

[0049] Wherein: the formula of the above-mentioned RY medium is: 100.0 g of skimmed milk powder, 8.0 g of yeast extract, 1.0 g of ascorbic acid, 9.0 g of calcium carbonate, and 1000 mL of distilled water;

[0050] (4) Insert the bacterium liquid of Lactobacillus delbrueckii subsp. bulgaricus prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com