Focus detection method based on grating Talbot effect

A technology of Taber and focus detection, which is applied in optics, optical components, and optical devices, etc., can solve the problems of inability to take into account focus detection accuracy and efficiency, low system anti-interference ability, etc., and achieve high engineering practicability and high anti-interference ability. Ability, the effect of high focus detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

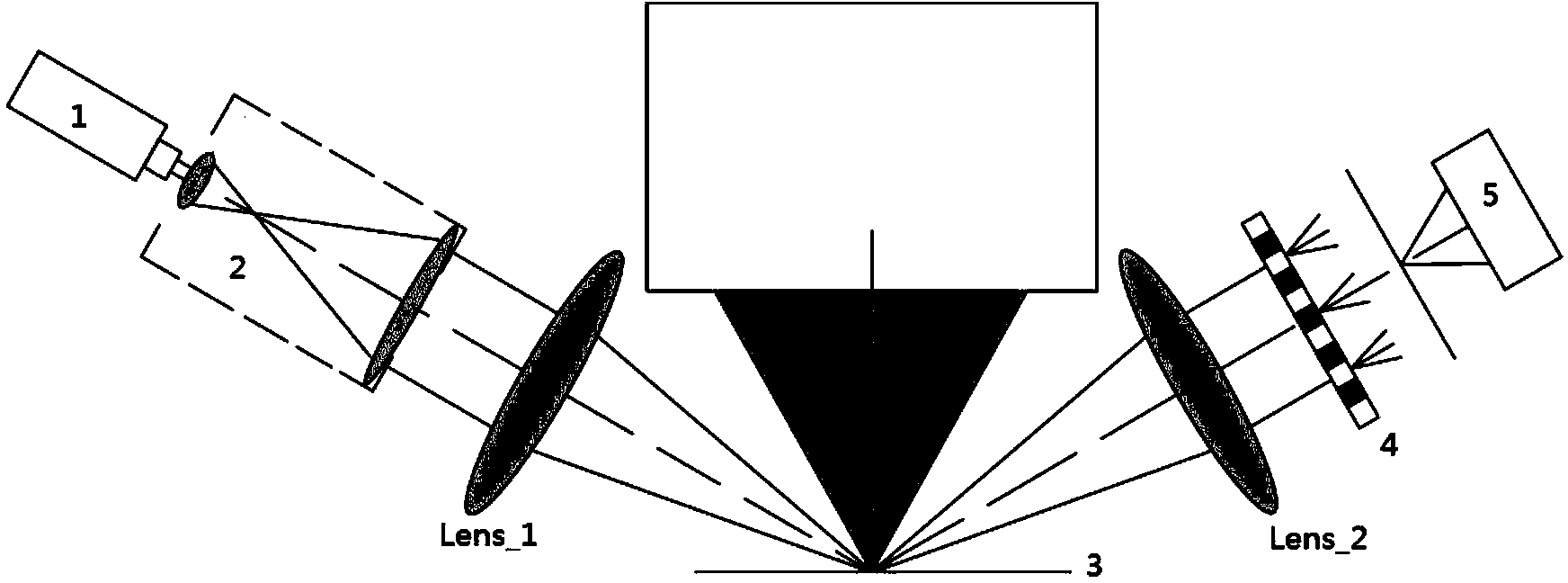

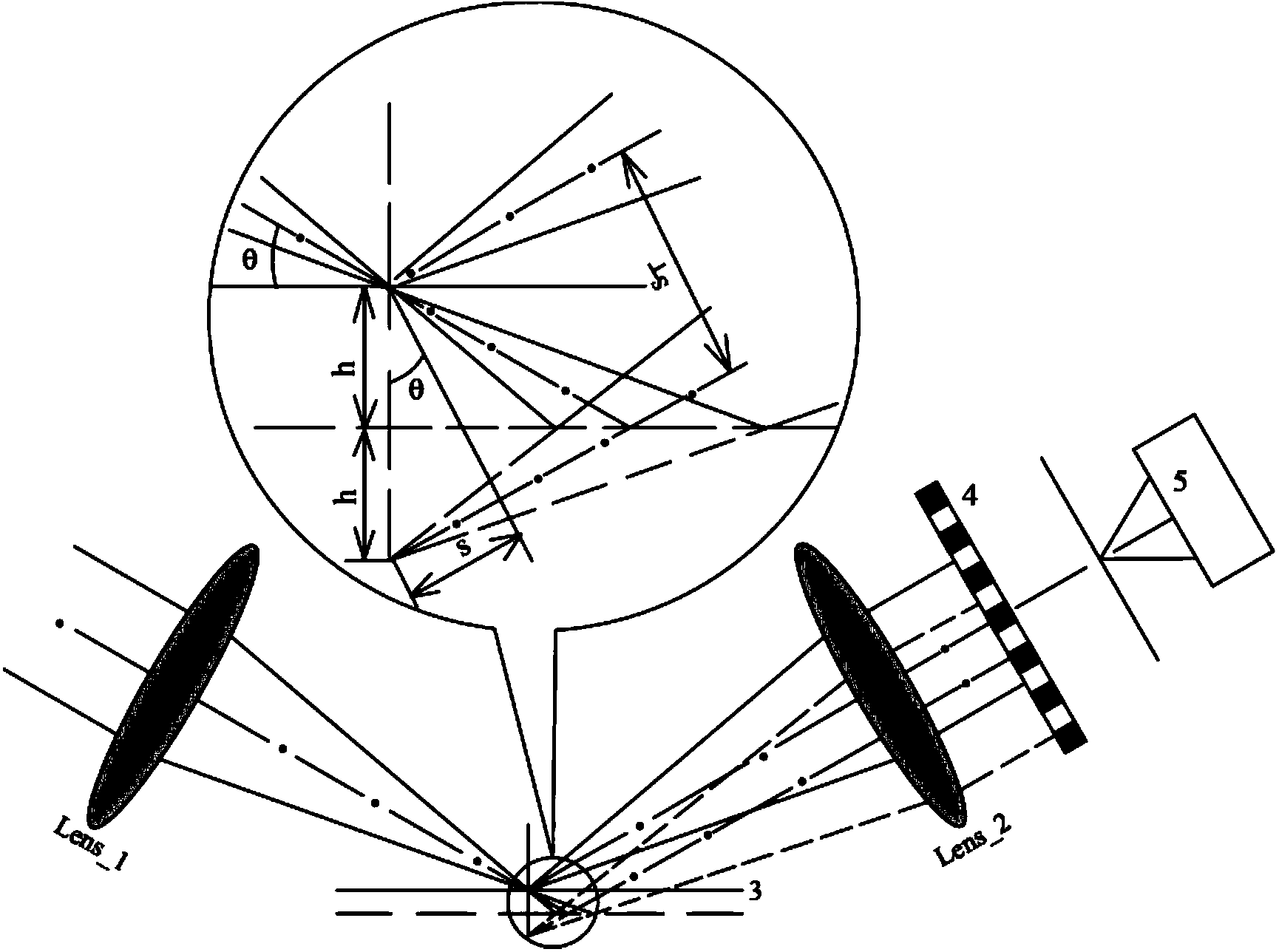

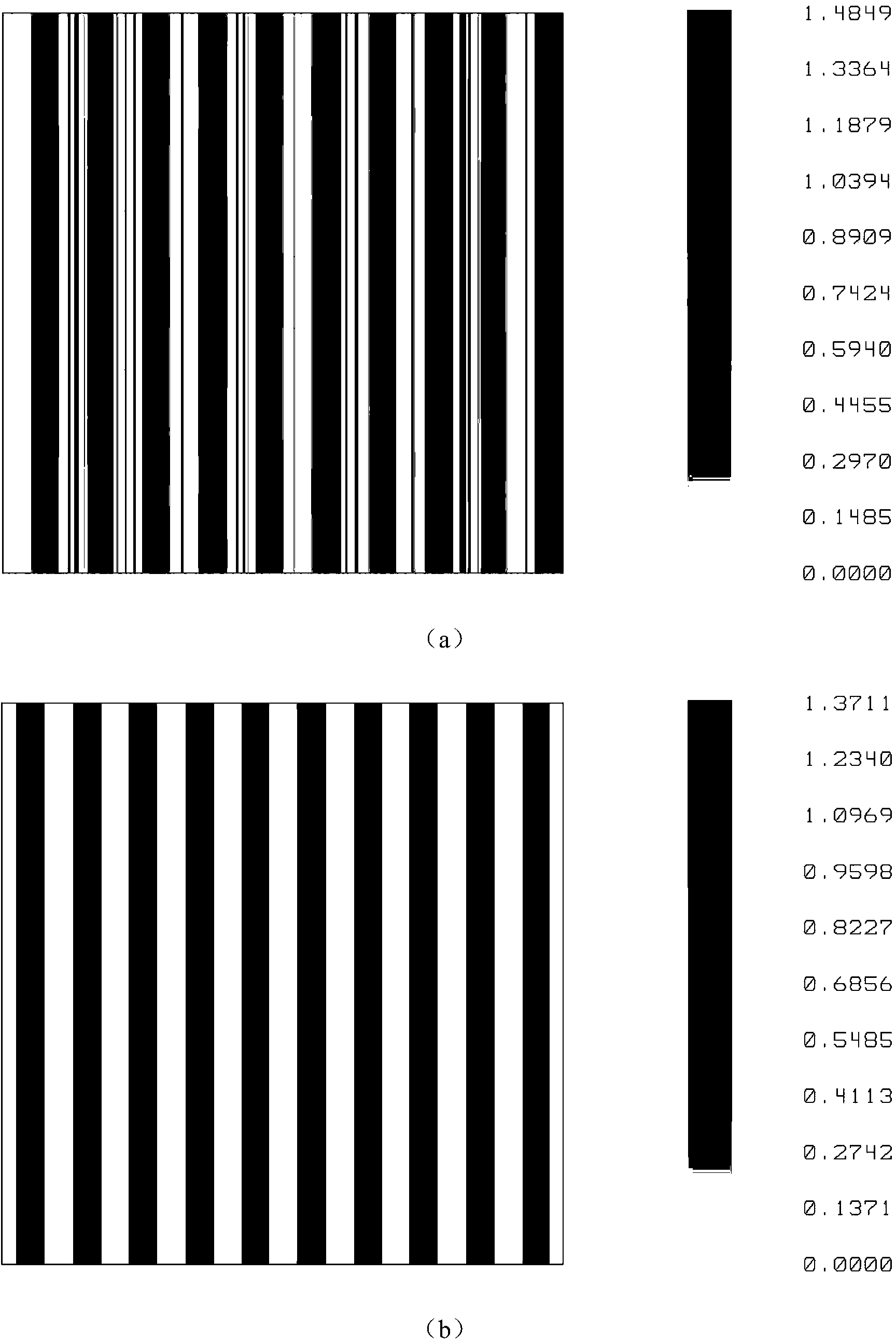

[0020] In order to realize the on-line precision focus measurement of silicon wafers in the lithography system, this project is based on the Talbot effect of gratings. By analyzing the phase distribution of the interference fringes of the Talbot effect, the high-precision focus measurement of silicon wafers is completed. The focus detection system is as follows: figure 1 shown.

[0021] The focus detection method based on the grating Taber effect and applied to high-precision photolithography machines according to the present invention is characterized in that: the detection system is a 4f optical system consisting of a light source 1, a beam collimation and beam expansion system 2, and lens groups Lens_1 and Lens_2. system, tested silicon wafer 3, diffraction grating 4 and CCD detector 5. 4f optical system composed of lens groups Lens_1 and Lens_2: when the tested silicon wafer 3 is located on the confocal plane of the 4f system, the outgoing plane wavefront of the collimated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com