Direct-drive wind power conversion structure based on MMC and bipolar direct-current transmission structure

A DC transmission, bipolar technology, applied in the conversion of AC power input to AC power output, wind power generation, output power conversion devices, etc., can solve the problems of power device heating, system cost increase, system efficiency reduction, etc., to achieve Effects of low switching loss, space saving, and simple topology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

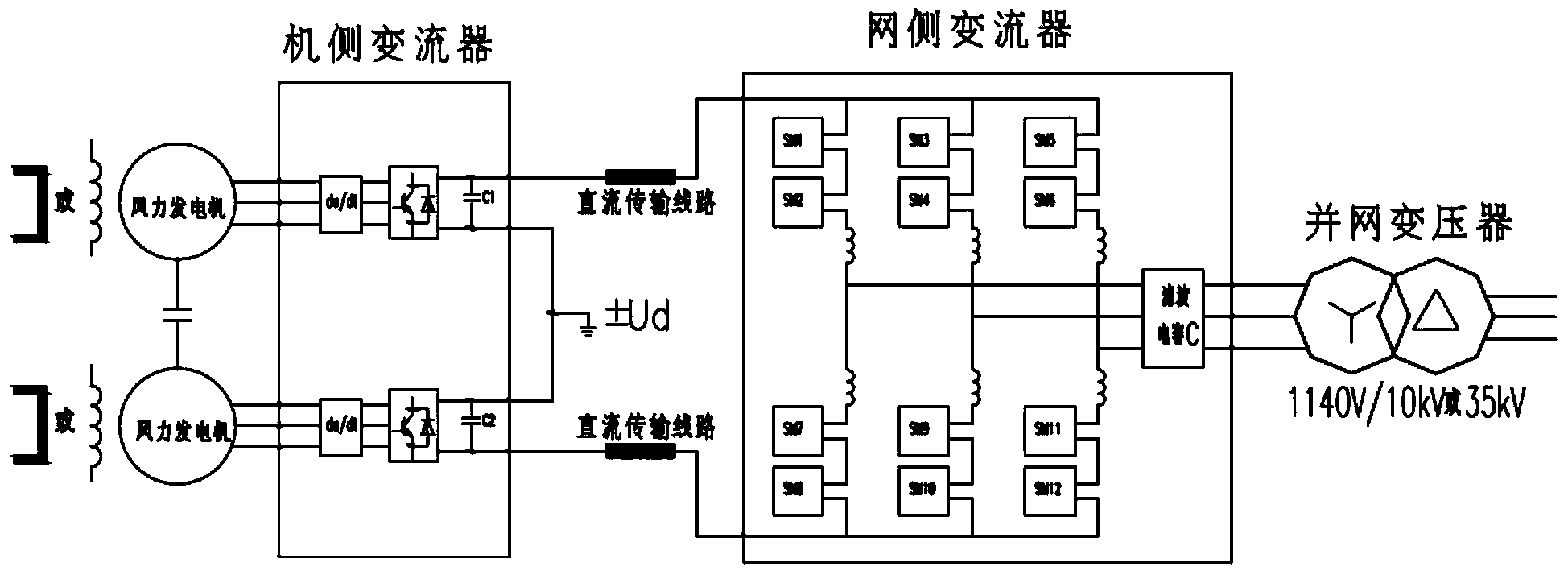

[0031] Such as figure 1As shown, this embodiment provides a direct-drive wind power conversion structure based on MMC and bipolar DC transmission structure, including two direct-drive wind generators, machine-side converters, grid-side converters and grid-connected The transformer and the machine-side converter are composed of two independent rectification circuits, each rectification circuit includes a du / dt filter, a controllable rectifier, and a DC capacitor, and the rectification input terminals are respectively connected to two single-winding electric excitation direct drive The wind turbine is connected to rectify the three-phase AC generated by the wind turbine into a DC voltage. The four rectification circuits are connected in parallel with the two outputs of the motor, and then grounded in series, so that the entire machine-side converter outputs a bipolar DC voltage. ;

[0032] The grid-side converter is mainly composed of three groups of modular multilevel converte...

Embodiment 2

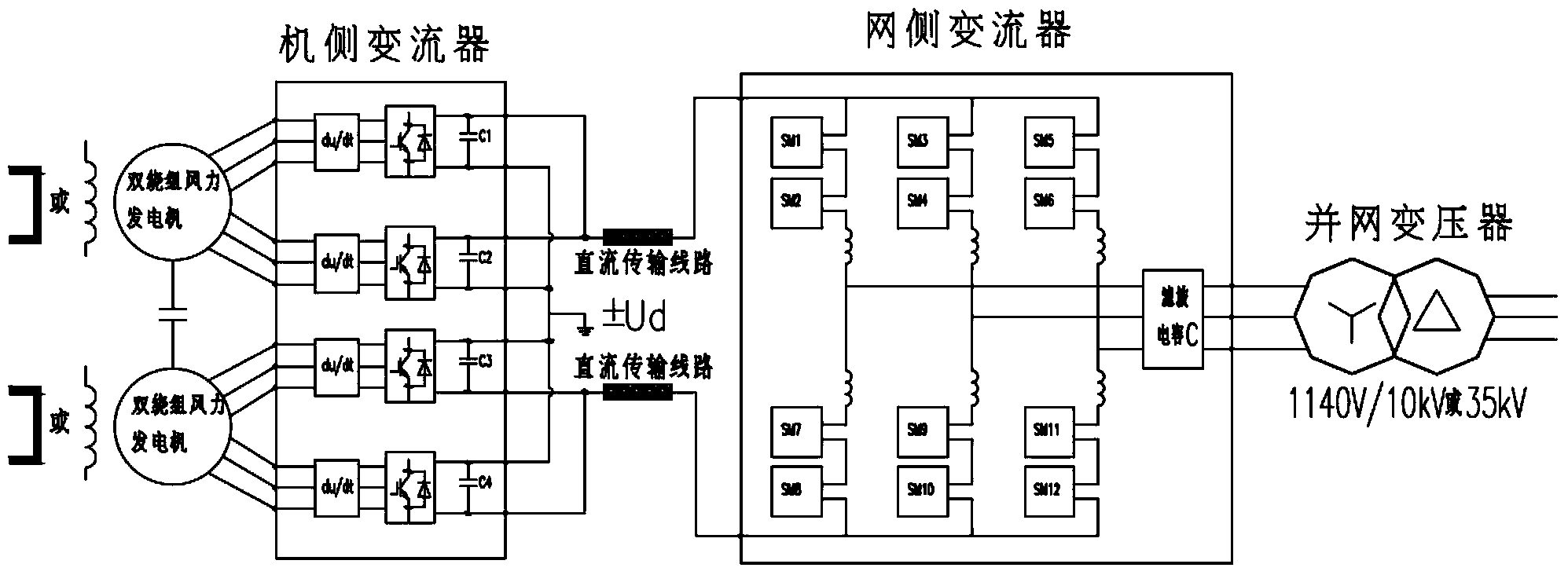

[0035] Such as figure 2 As shown, this embodiment provides a direct-drive wind power conversion structure based on MMC and bipolar DC transmission structure, including two direct-drive wind generators, machine-side converters, grid-side converters and grid-connected The transformer and the direct-drive wind turbine are double-winding direct-drive wind turbines, and each set of three-phase windings is set independently. The output end of each set of three-phase windings is connected in series with a du / dt filter and a rectifier, that is, each set of two-phase The winding direct drive wind turbine is connected with two du / dt filters and two rectifiers;

[0036] The positive DC output terminals of the two rectifiers connected to the first double-winding direct-drive wind turbine are connected in series with the first DC resistor and then connected to the grid-side converter through the positive DC transmission line. The negative DC output terminals of the two connected rectifie...

Embodiment 3

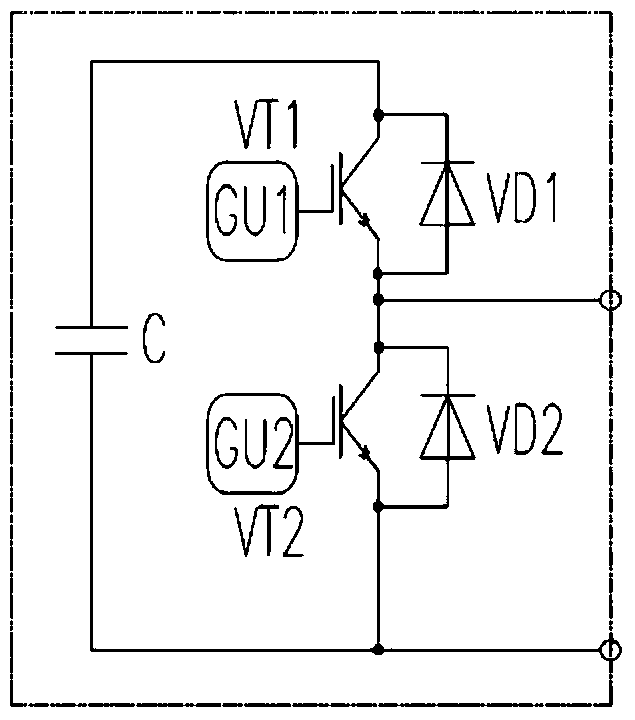

[0039] Such as image 3 As shown, in this embodiment, the SM sub-module adopts a half-bridge structure, which is composed of 2 insulated gate bipolar transistors IGBT and 1 DC energy storage capacitor, and the IGBTs are respectively connected in parallel with a reverse diode VD, by controlling VT1 and VT2 Turning on and off can realize the state of putting in, cutting out and blocking of the sub-module. Further reasoning, at any time, the output of AC voltage can be adjusted by adjusting the number of sub-modules invested in the upper and lower bridge arms, and at the same time, the number of sub-modules invested in each phase unit remains constant to maintain a constant DC voltage, so MMC The number of output levels is n+1; the inverter modulates the DC voltage rectified by the machine-side converter into an AC three-phase voltage, and realizes the three-phase AC voltage by controlling the on and off of the switching devices of each power unit Synthesis, connected to the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com