Spherical mesoporous sepiolite composite carrier, catalyst and preparation method and application thereof and preparation method of ethyl acetate

A composite carrier, sepiolite technology, applied in the preparation of organic compounds, catalyst carriers, chemical instruments and methods, etc., can solve the problems of complex product separation, many side reactions, large equipment investment, etc., to broaden the application field, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

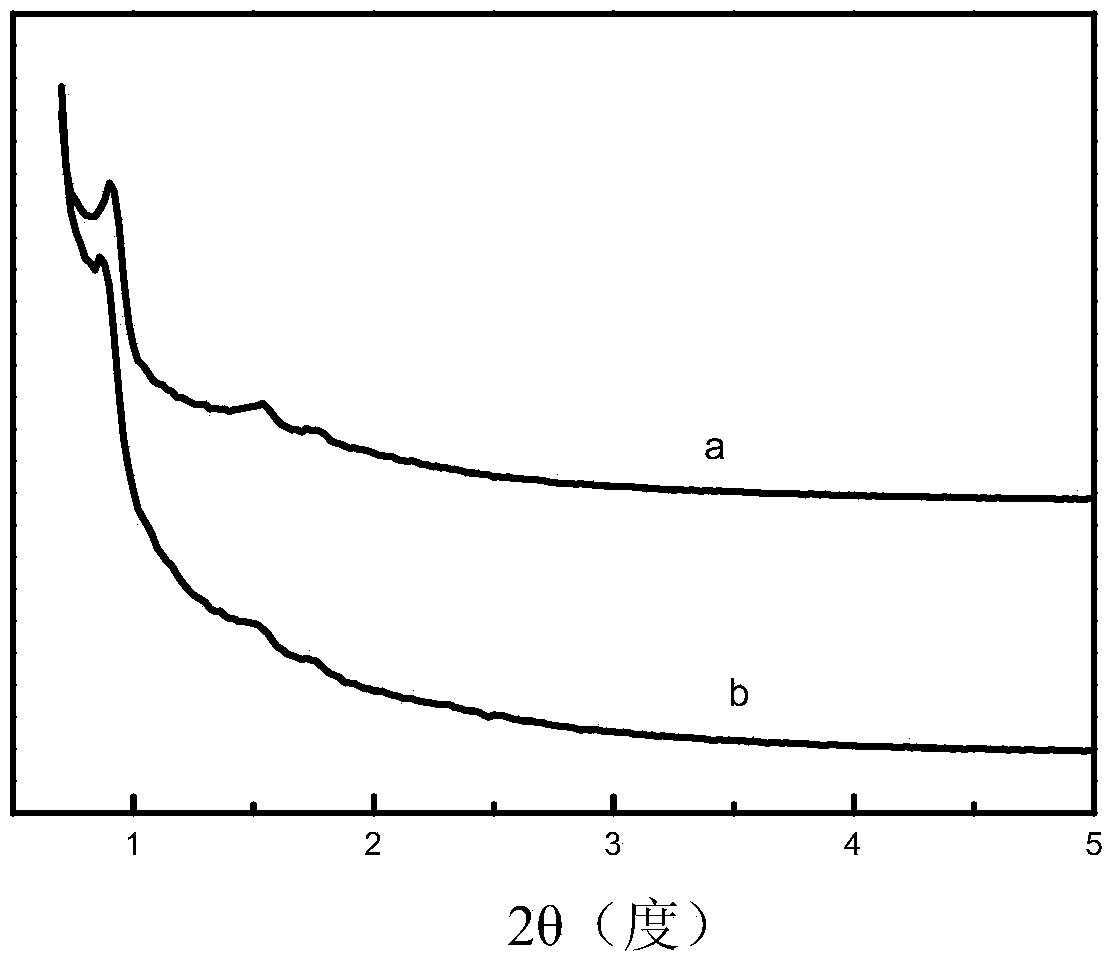

[0031] The preparation method of spherical mesoporous sepiolite composite carrier provided by the invention comprises the following steps:

[0032] (1) In the presence of a template, trimethylpentane and ethanol, tetramethoxysilane is first contacted with an acid agent, and the product obtained after the first contact is crystallized and filtered to obtain No. 1 medium Porous material filter cake; second contacting cetyltrimethylammonium bromide, tetraethylorthosilicate and ammonia water, and filtering the product after the second contacting, to obtain No. 2 mesoporous material filter cake;

[0033] (2) performing a third contact with water glass and inorganic acid, and filtering the product obtained after the third contact to obtain a silica gel filter cake;

[0034] (3) Mix the No. 1 mesoporous material filter cake, No. 2 mesoporous material filter cake, silica gel filter cake and sepiolite evenly and ball mill, and the solid powder obtained after ball milling is slurried wi...

Embodiment 1

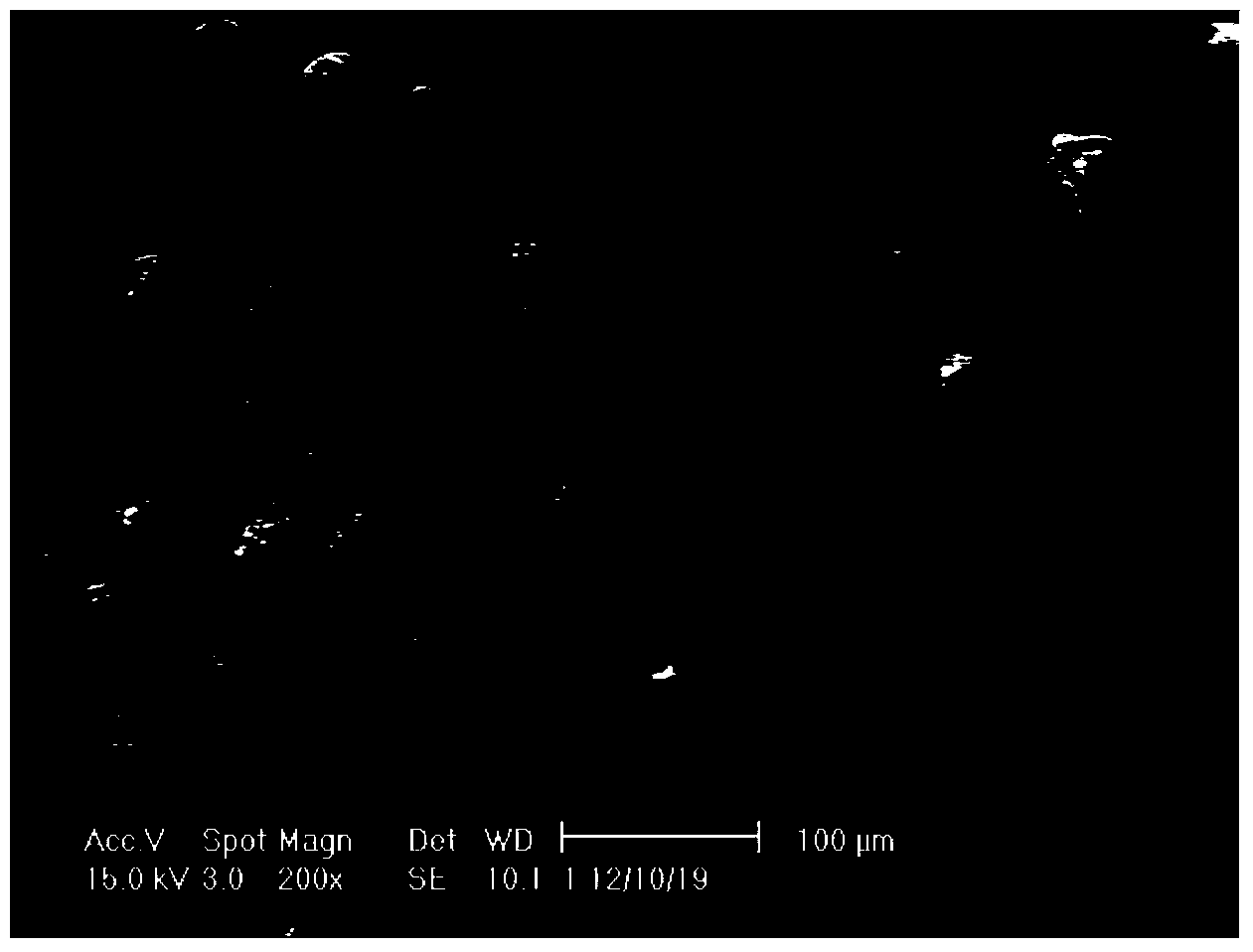

[0072] This example is used to illustrate the spherical mesoporous sepiolite composite carrier and catalyst provided by the present invention and the preparation method thereof.

[0073] (1) Preparation of spherical mesoporous sepiolite composite support:

[0074] Add 1.0 g of triblock copolymer P123 and 1.69 g (0.037 mol) of ethanol to 28 mL of a buffer solution of acetic acid and sodium acetate with a pH value of 4, stir at 15 °C until P123 is completely dissolved, and then add 6 g (0.053 mol) of trimethylpentane, and stirred at 15°C for 8 hours, then added 2.13 g (0.014mol) of tetramethoxysilane, then stirred at 15°C and pH 4.5 for 20 hours, and The solution was transferred to a polytetrafluoroethylene-lined reactor, and oven-crystallized at 60° C. for 24 hours. The obtained crystallized product was suction-filtered and washed four times with distilled water to obtain No. 1 mesoporous material filter cake.

[0075] At 80°C, cetyltrimethylammonium bromide and ethyl orthosil...

Embodiment 2

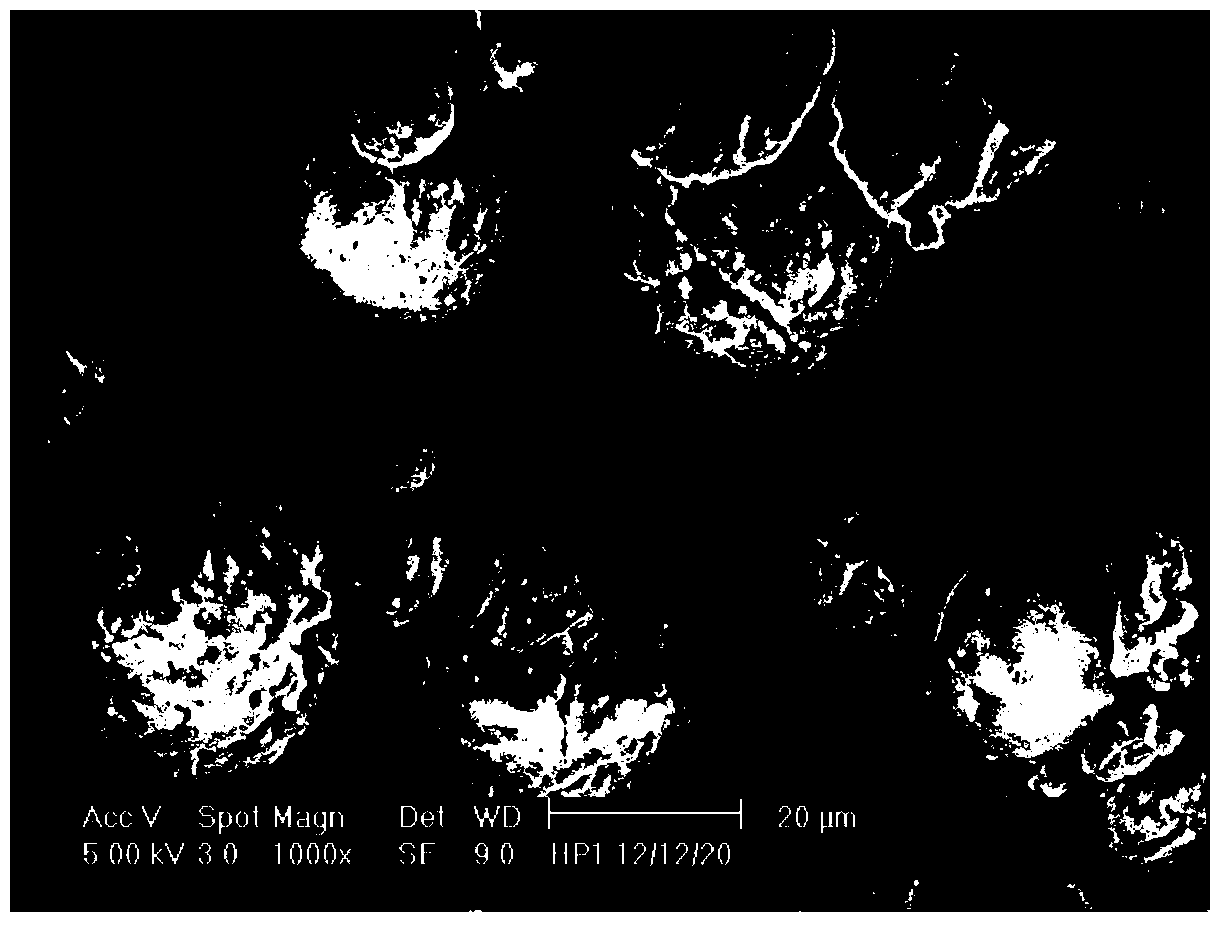

[0098] This example is used to illustrate the spherical mesoporous sepiolite composite carrier and catalyst provided by the present invention and the preparation method thereof.

[0099] (1) Preparation of spherical mesoporous sepiolite composite support:

[0100] Add 1.0 g of triblock copolymer P123 and 3.69 g (0.08 mol) of ethanol to 28 mL of a buffer solution of acetic acid and sodium acetate with a pH value of 5, stir at 60 °C until P123 is completely dissolved, and then add 9.14 g ( 0.08mol) of trimethylpentane, and stirred at 60°C for 1 hour, then added 4.68 grams (0.03mol) of tetramethoxysilane, then stirred at 60°C and pH value of 5.5 for 10 hours, and The solution was transferred to a polytetrafluoroethylene-lined reactor, and oven crystallized at 30° C. for 72 hours. The obtained crystallized product was suction-filtered and washed four times with distilled water to obtain No. 1 mesoporous material filter cake.

[0101] At 100°C, cetyltrimethylammonium bromide and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com