Isobutene preparation method

A technology of isobutene and isobutane, applied in the field of isobutene preparation, can solve the problems of low utilization rate of LPG and low economic added value, and achieve the effect of reducing the preparation cost and improving the yield of isobutene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of described isobutylene according to the present invention comprises the following steps:

[0023] (1) Separating isobutane from liquefied petroleum gas and hydrogenating other components;

[0024] (2) subjecting the hydrogenation reaction product obtained in step (1) to an isomerization reaction;

[0025] (3) Subjecting the isobutane separated in step (1) and / or the isomerization product obtained in step (2) to steam cracking reaction.

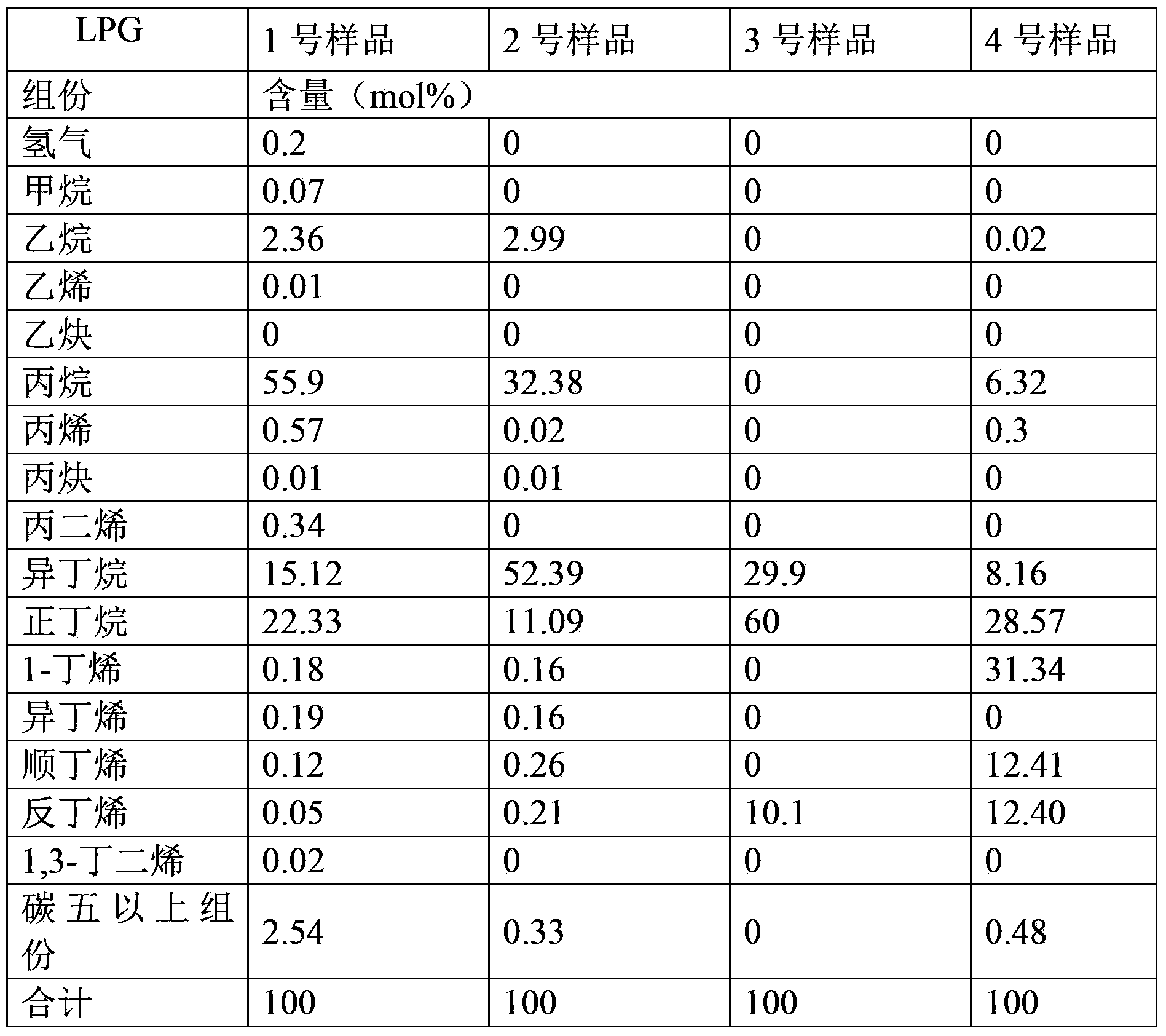

[0026] In the method for preparing isobutene according to the present invention, liquefied petroleum gas (LPG) refers to petroleum gas liquefied under pressure (about 1 MPa) at room temperature, and its main components are C3 and C4 hydrocarbons, except In addition, it also contains a very small amount of components below carbon 2 and components above carbon 5. Due to differences in the content of LPG components produced by different devices, the following table 1 lists the range of a certain LPG main componen...

preparation example 1

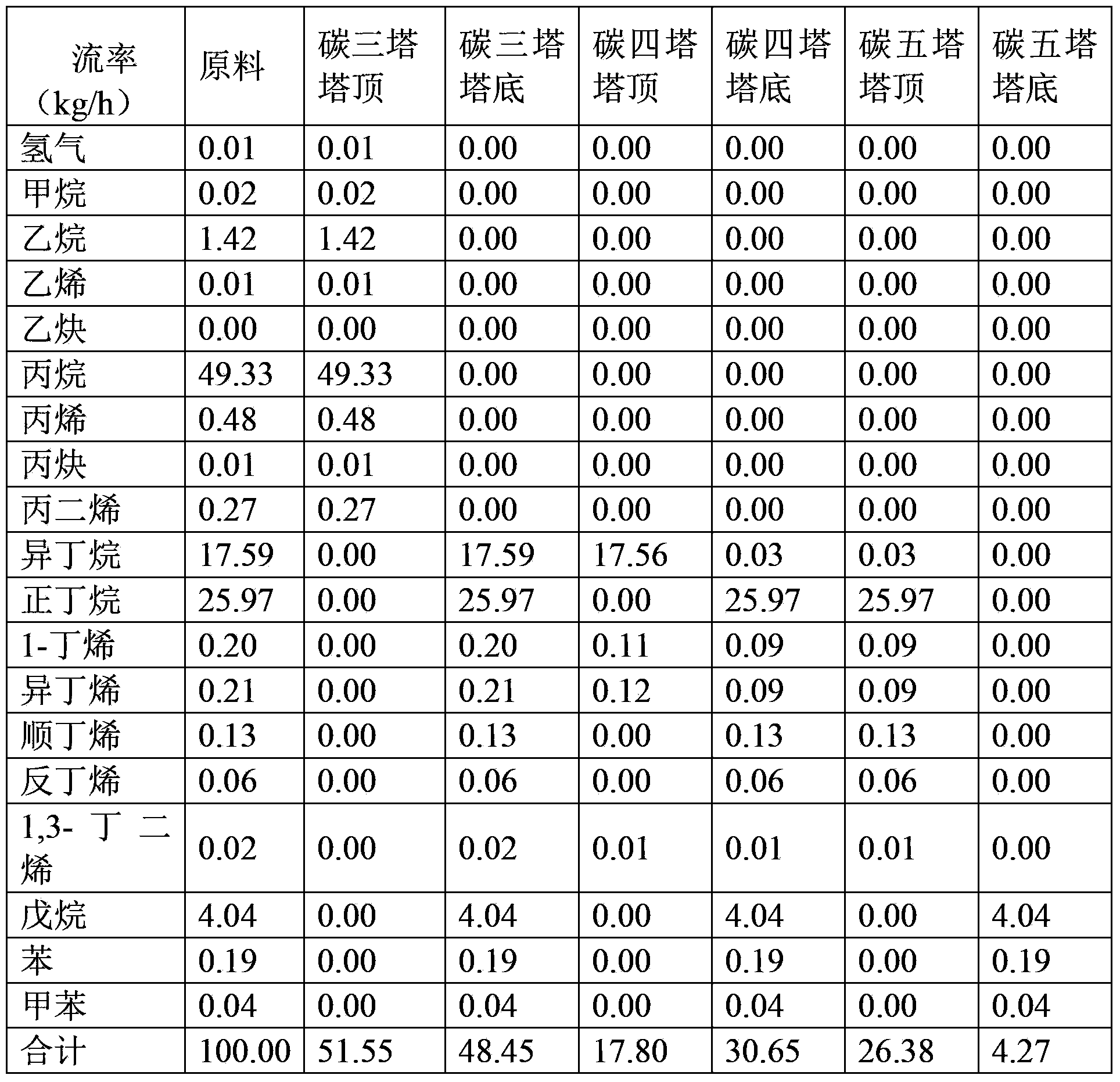

[0077] Based on the composition of the LPG of sample No. 1, the raw material feed rate is 100kg / h, the temperature is 40°C, and the pressure is 11atm into the separation system. The separation conditions of the LPG of the No. 1 sample are shown in Table 3. The separation of the LPG of the No. 1 sample The results are shown in Table 4.

[0078] table 3:

[0079]

Carbon three towers

Carbon Four Towers

carbon five tower

Theoretical number of boards

35.0

99.0

30.0

Tower top temperature ℃

25.4

34.1

50.5

Bottom temperature °C

76.9

60.3

94.8

Tower top pressure atm

10.0

4.5

5.0

Tower bottom pressure atm

10.1

6.0

5.1

Reflux ratio

10.0

20.0

3.0

[0080] Table 4:

[0081]

[0082] As can be seen from the above results, the mass content of isobutane in the C4 overhead material is 99% by weight, and the remainder is isobutene, 1-butene and tra...

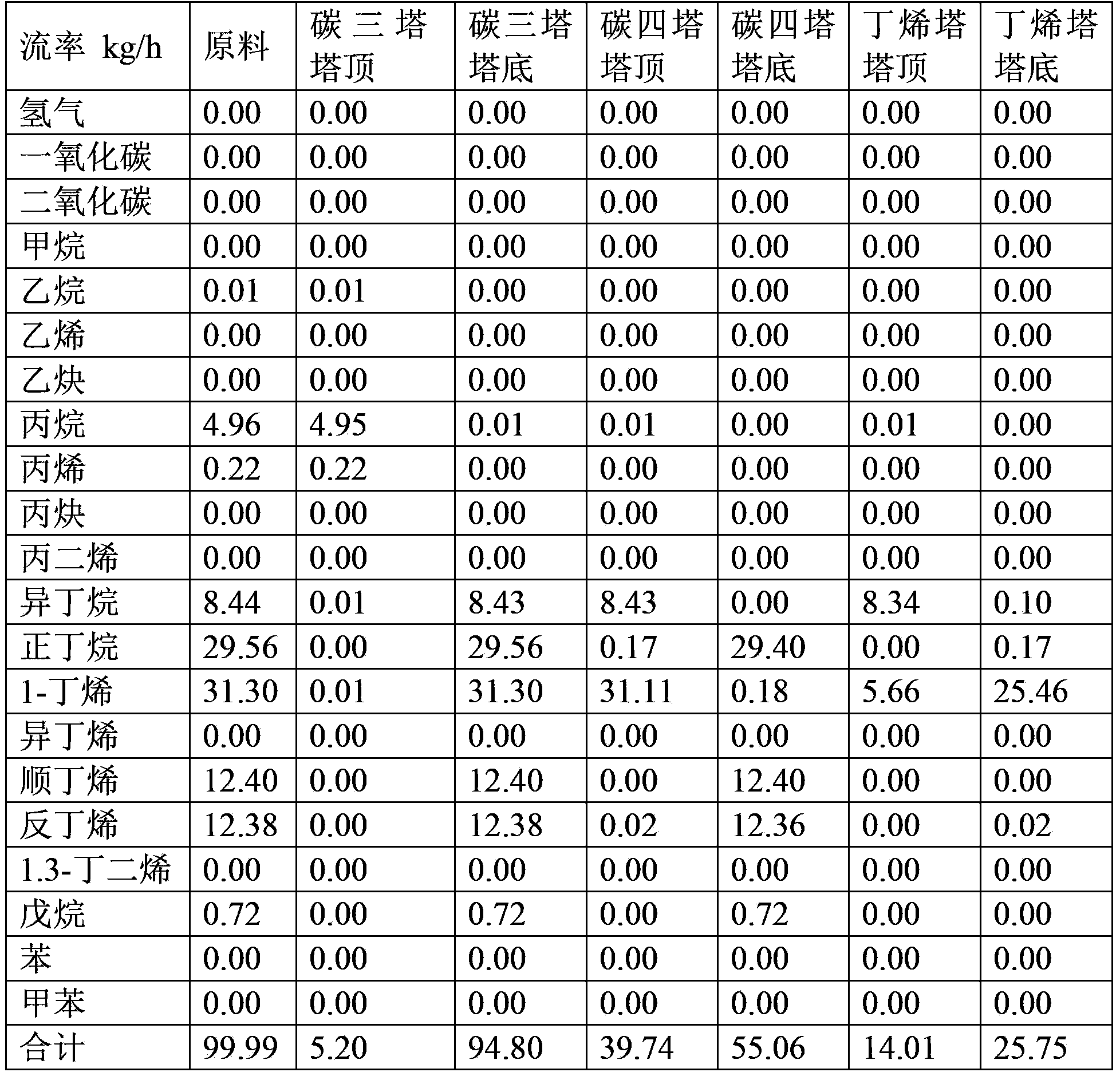

preparation example 2

[0092] Based on the composition of the LPG of sample No. 2, the raw material feed rate is 100kg / h, the temperature is 40°C, and the pressure is 11atm into the separation system. The separation conditions of the LPG of the No. 2 sample are shown in Table 5. The separation of the LPG of the No. 2 sample The results are shown in Table 6.

[0093] table 5:

[0094]

Carbon three towers

Carbon Four Towers

Theoretical number of boards

35.0

99.0

Tower top temperature ℃

24.2

34.1

Bottom temperature °C

69.2

58.3

Tower top pressure atm

10.0

4.5

Tower bottom pressure atm

10.1

6.0

Reflux ratio

10.0

20.0

[0095] Table 6:

[0096] Flow ratekg / h

Carbon three tower top

Carbon three tower bottom

C4 tower top

C4 tower bottom

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com