Uvioresistant polyving alcohol-xylan composite membrane as well as preparation method and application thereof

A technology of polyvinyl alcohol and xylan, applied in the field of agricultural waste utilization and food packaging materials, to achieve the effects of improved mechanical properties, easy access, and good UV shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

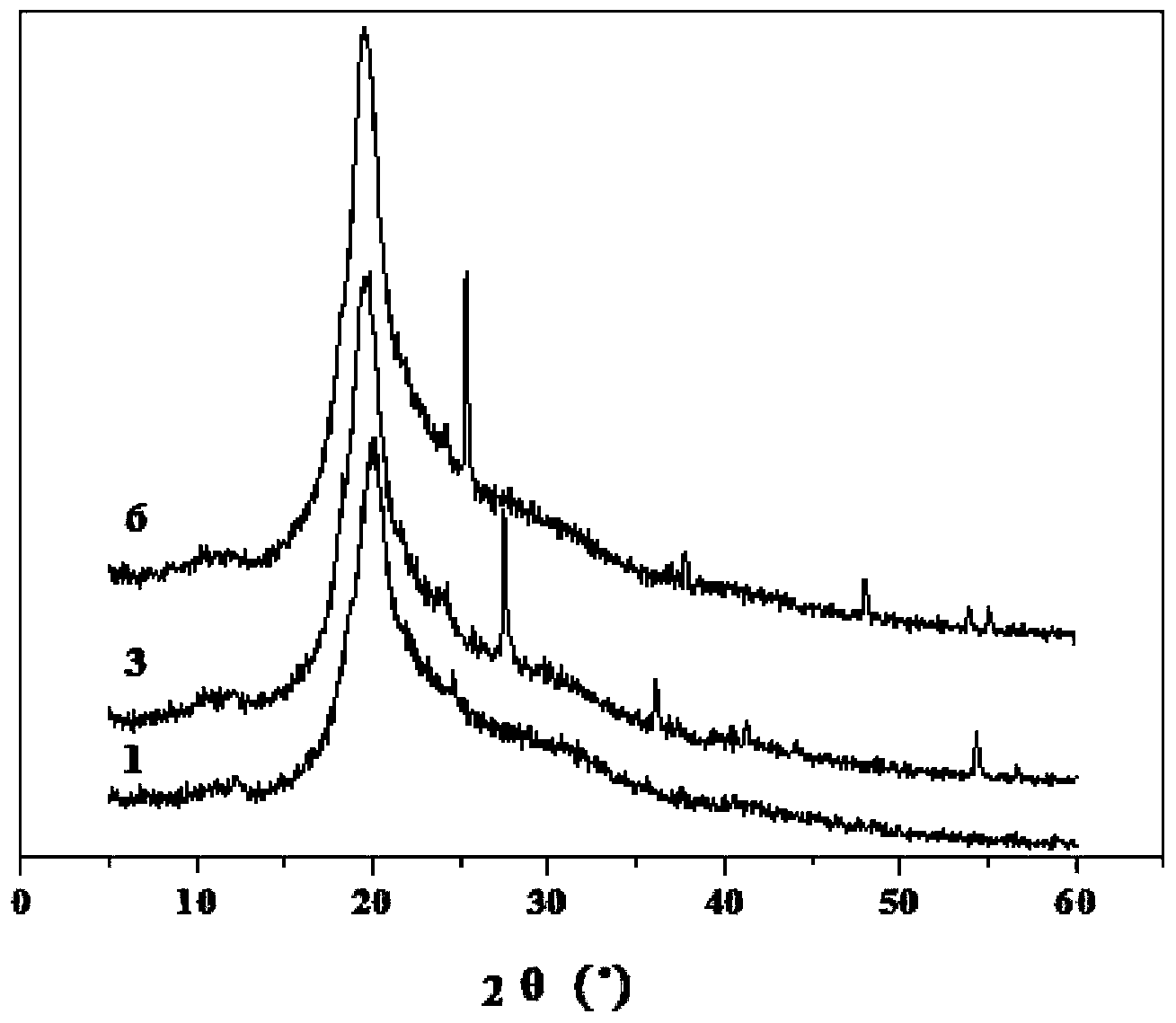

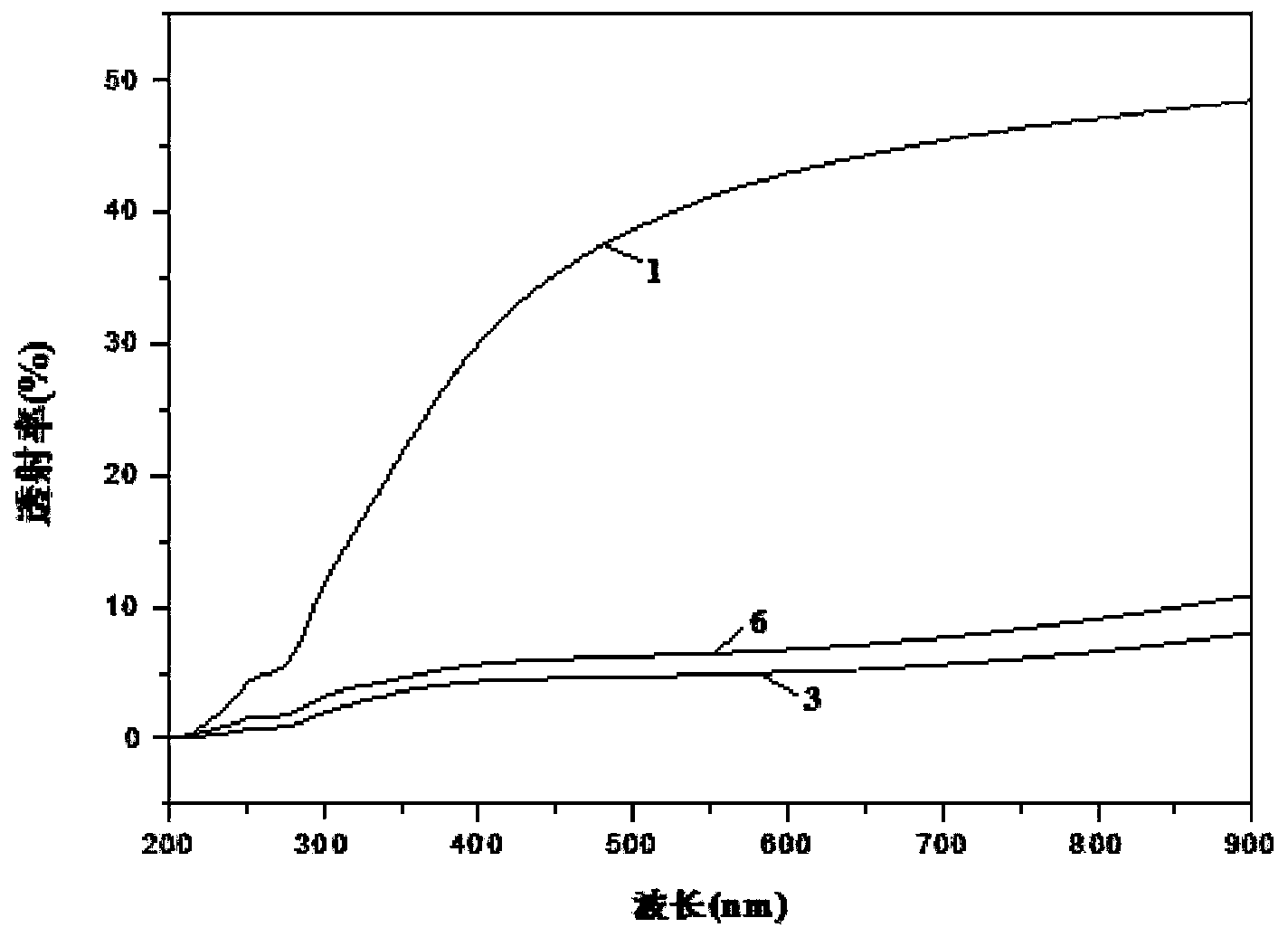

[0048] A kind of anti-ultraviolet polyvinyl alcohol-xylan composite film, its preparation method is as follows:

[0049] (1) Weigh 3g of polyvinyl alcohol with a molecular weight of 179687g / mol and 1g of xylan with a molecular weight of 131463g / mol, add them to 200mL of 95°C hot water for 1 hour, then add 0.4g of glycerin, and mix well solution;

[0050] (2) Continue to stir the mixed solution for 1 h, then add 0.08 g of rutile titanium dioxide, and place it in a 90W ultrasonic instrument for ultrasonication for 1 h to obtain a composite film-making solution;

[0051] (3) Pour the composite film-making solution into a horizontally placed polytetrafluoroethylene plate for casting, then put it in a blast drying oven at 40°C for 12 hours, and then place it in a constant temperature and constant temperature at 23°C and a relative humidity of 50%. After 48 hours in a wet chamber, the anti-ultraviolet polyvinyl alcohol-xylan composite film was obtained.

Embodiment 2

[0054] A kind of anti-ultraviolet polyvinyl alcohol-xylan composite film, its preparation method is as follows:

[0055] (1) Weigh 3g of polyvinyl alcohol with a molecular weight of 179687g / mol and 1g of xylan with a molecular weight of 131463g / mol, add them to 200mL of 100°C hot water for 1 hour, then add 0.32g of glycerin, and mix well solution;

[0056] (2) Continue stirring the mixed solution for 2 hours, then add 0.16 g of anatase titanium dioxide, and place it in a 100W ultrasonic instrument for 1.5 hours to obtain a composite film-forming solution;

[0057] (3) Pour the composite film-making solution into a horizontally placed polytetrafluoroethylene plate for casting, then put it in a blast drying oven at 45°C for 24 hours, and then place it in a constant temperature and constant temperature at 23°C and a relative humidity of 50%. After 48 hours in a wet chamber, the anti-ultraviolet polyvinyl alcohol-xylan composite film was obtained.

[0058] The properties of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com