Grain characteristic-based improved split spectrum method in cast iron ultrasonic flaw detection

An ultrasonic flaw detection and cast iron technology, applied in the direction of processing the response signal of detection, can solve the problems of low signal-to-noise ratio of echo signals, and achieve the effects of noise reduction, signal sensitivity improvement, and high signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

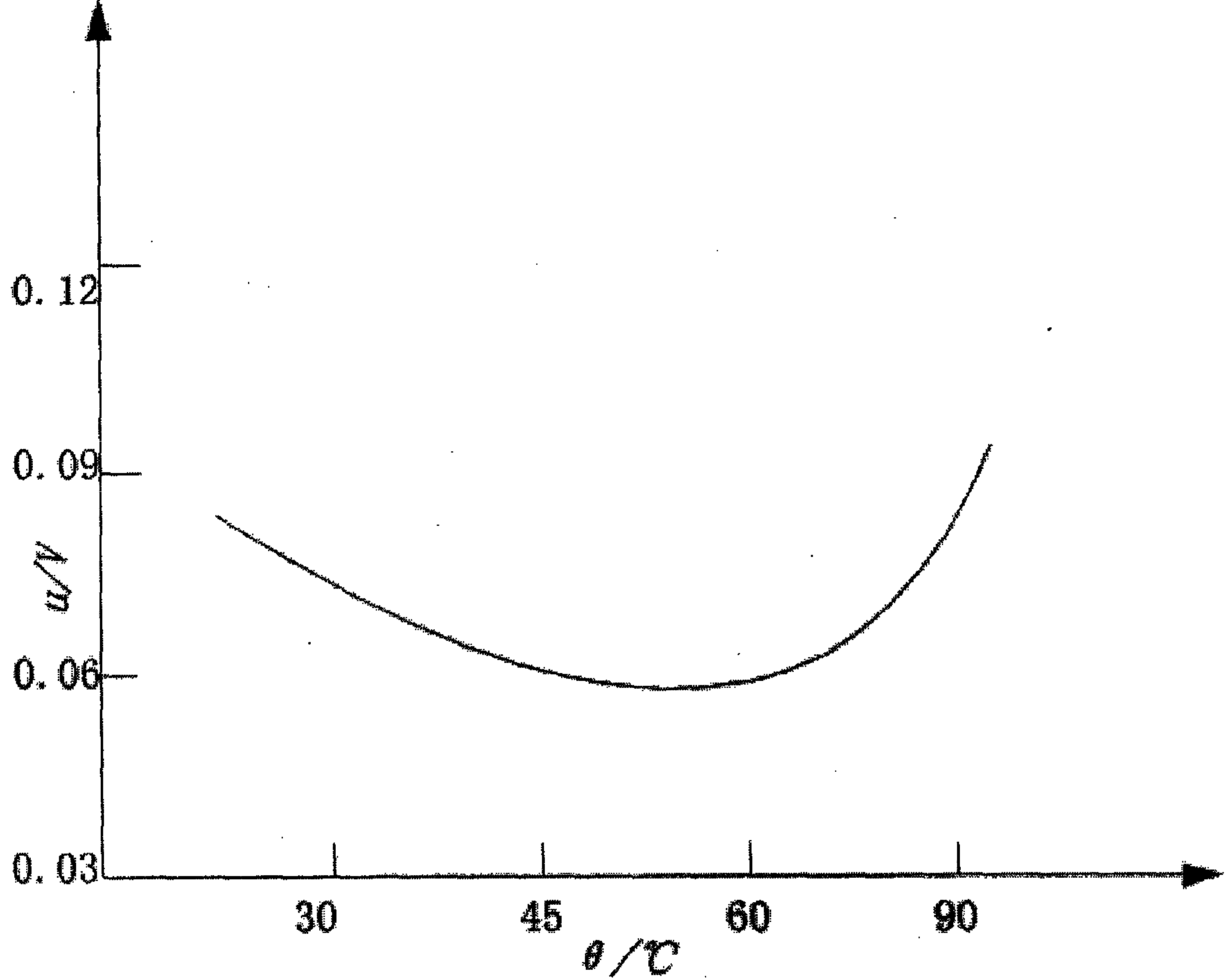

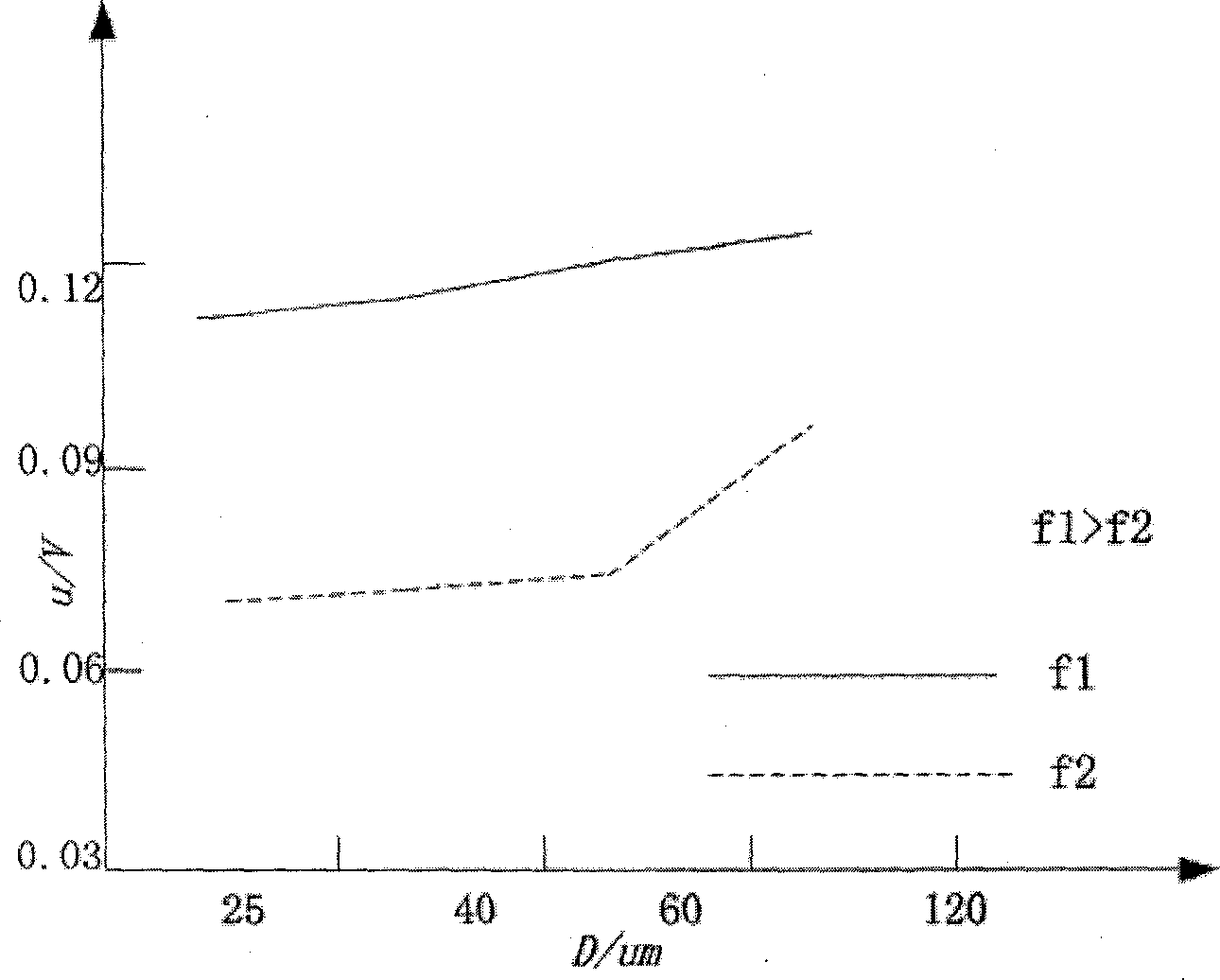

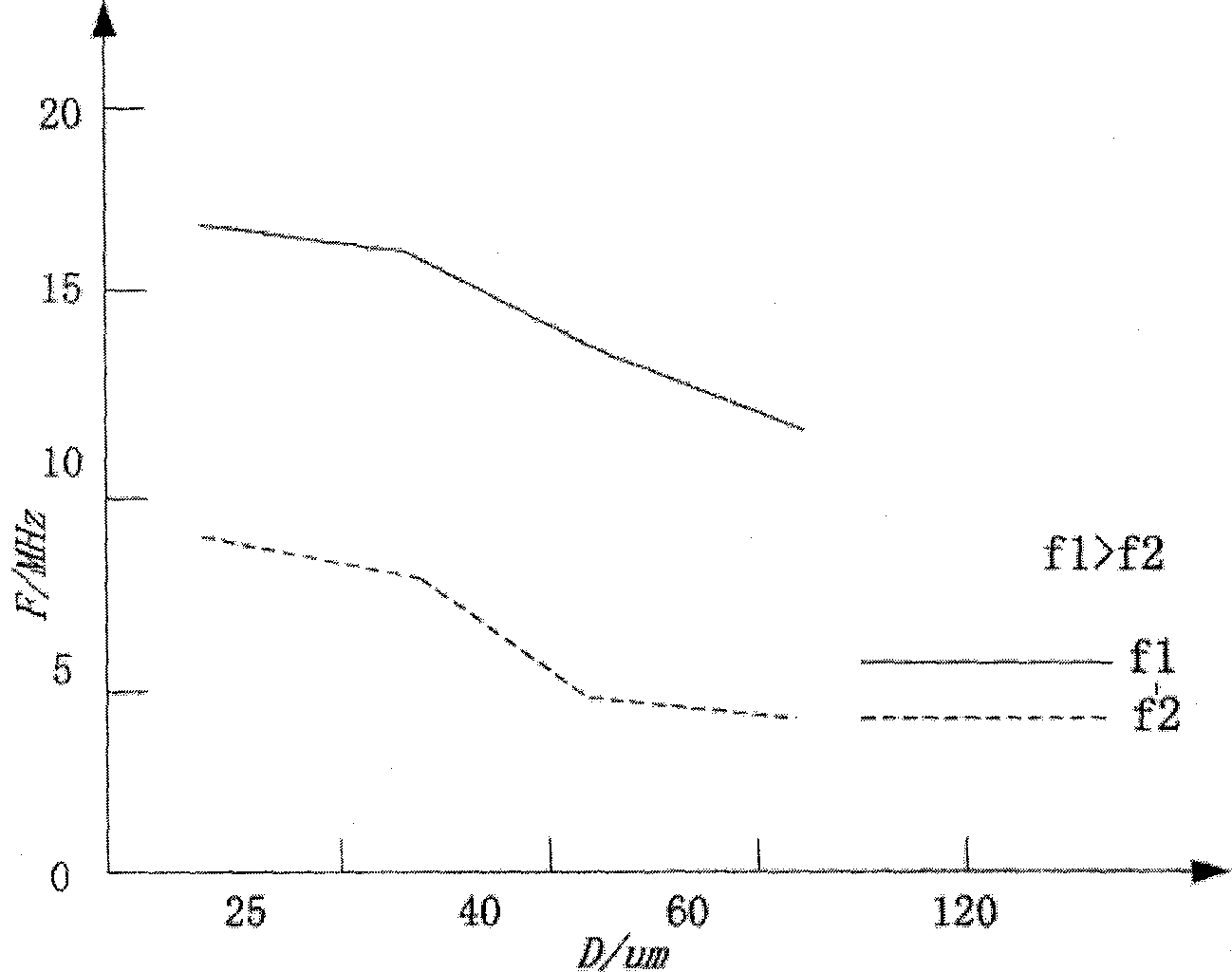

[0013] The central idea of improving the separation spectrum method in the ultrasonic testing of pressure-bearing cast iron equipment is: when using a broadband ultrasonic transducer for ultrasonic testing, the frequency spectrum of the echo and noise distribution in the ultrasonic signal is analyzed, and the analysis results for the crystal grains of such materials and detection conditions, the frequency domain characteristics of the structure noise and the dispersion characteristics of the echo signal, thereby optimizing and determining the bandwidth, cutoff frequency and transition band parameters of the filter bank, and then overlapping the ultrasonic signals through the set N frequency bands The filter is used to restore these time-domain signals through processing based on certain characteristics, thereby improving the signal-to-noise ratio of the echo signal and the detection sensitivity of the detection equipment.

[0014] As for the optimization of the bandwidth, cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com