Method for remediating heavy metal polluted soil by comprehensively utilizing biochemical resources

A technology that pollutes soil and heavy metals, applied in the field of soil remediation, can solve the problems of high remediation cost and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

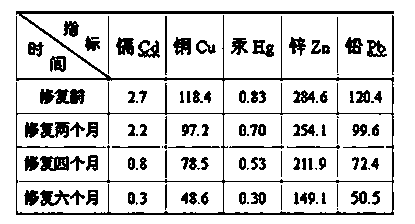

Image

Examples

Embodiment 1

[0029] Example 1 The method of comprehensively utilizing biochemical resources to remediate heavy metal-contaminated soil includes three processes: pesticide spraying, earthworm enrichment and remediation, and microbial decomposition. The insecticide is prepared from the following materials, all in parts by mass: 280kg of organic fertilizer, 28kg of microbial agent, 0.05kg of pyrethrum, 0.03kg of deervine and 0.02kg of Bacillus thuringiensis powder.

[0030] The preparation technology of described insecticide is:

[0031] ① Put the organic fertilizer on a sterile plastic film, spread it flat, cover it with a sterile plastic film for ultraviolet sterilization for 1 day, remove the film, put it in a cool place, add microbial agents and mix well for later use;

[0032] ②Put pyrethrum and deer vine in a non-iron container, soak in warm water at a temperature of 10-20°C for 30 minutes. Boil for 30 minutes, let stand for 5 hours, and take the supernatant for later use;

[0033] ③...

Embodiment 2

[0039] Example 2 The method of comprehensively utilizing biochemical resources to remediate heavy metal-contaminated soil includes three processes: pesticide spraying, earthworm enrichment and remediation, and microbial decomposition. The insecticide is prepared from the following materials, all in parts by mass: 320kg of organic fertilizer, 32kg of microbial agent, 0.1kg of pyrethrum, 0.09kg of deervine and 0.06kg of Bacillus thuringiensis powder.

[0040] The preparation technology of described insecticide is:

[0041] ① Put the organic fertilizer on a sterile plastic film, spread it flat, cover it with a sterile plastic film and sterilize it with ultraviolet light for 5 days, remove the film, put it in a cool place, add microbial agents and mix well for later use;

[0042] ②Put pyrethrum and deer vine in a non-iron container, soak in warm water at a temperature of 10-20°C for 30 minutes, the water consumption is 5 times the weight of the raw materials, put it on a smokele...

Embodiment 3

[0050] Example 3 The method of comprehensively utilizing biochemical resources to remediate heavy metal-contaminated soil includes three processes: pesticide spraying, earthworm enrichment and remediation, and microbial decomposition. The insecticide is prepared from the following materials, all in parts by mass: 290kg of organic fertilizer, 29kg of microbial agent, 0.06kg of pyrethrum, 0.05kg of deervine and 0.03kg of Bacillus thuringiensis powder.

[0051] The preparation technology of described insecticide is:

[0052] ① Put the organic fertilizer on a sterile plastic film, spread it flat, cover it with a sterile plastic film and sterilize it with ultraviolet light for 2 days, remove the film, put it in a cool place, add microbial agents and mix well for later use;

[0053] ②Put pyrethrum and deer vine in a non-iron container, soak in warm water at a temperature of 10-20°C for 30 minutes, the water consumption is 3.5 times the weight of the raw materials, put it on a smok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com