Preparation method of one-step sintered glass-ceramic composite board

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of architectural ceramics, can solve the problems that glass-ceramic frit particles cannot play a role of bonding and fixation and are easily sucked away, and achieves the improvement of qualified yield and improvement The effect of flatness, avoidance of pinholes and air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

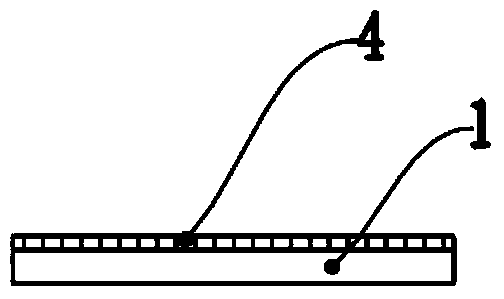

[0026] A method for preparing a once-fired transparent glass-ceramic composite board, comprising the following steps:

[0027] A. Green body stamping and forming: After the green body powder (fineness is 150 degrees) and micropowder powder (fineness is 150 degrees) are layered, punched into a green body with a bottom blank layer and a micropowder layer, wherein the micropowder layer The thickness is 1 / 2 of the thickness of the bottom layer, dry;

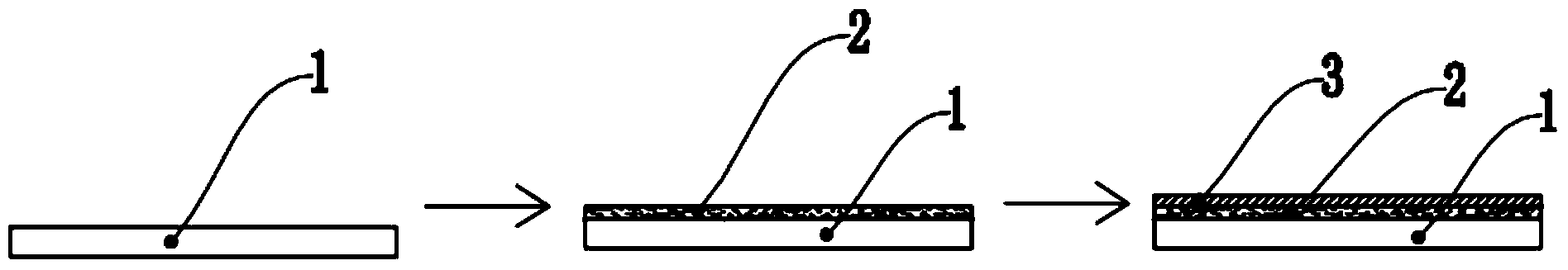

[0028] B. Apply glass-ceramic frit: spread transparent glass-ceramic frit on the surface of the body in step A and spray a layer of polyurethane fixative, the thickness of the transparent glass-ceramic frit spread is 2mm, and the amount of fixative is 300-500g / m2, obtained as figure 1 The adobe shown has a body layer 1, a glass-ceramic frit layer 2 and a fixing layer 3;

[0029] The component of every 100kg polyurethane fixative: nonionic polyurethane associative thickener (Nae Woi Korea., Ltd. company, model HIRESOL85) 4.3kg, atta...

Embodiment 2

[0051] A method for preparing a glass-ceramic composite plate with an ice crystal effect by firing once, comprising the following steps:

[0052] A. Green body stamping and forming: After the green body powder (fineness is 100 degrees) and micropowder powder (fineness is 100 degrees) are layered, punched into a green body with a bottom blank layer and a micropowder layer, wherein the micropowder layer The thickness is 1 / 3 of the bottom base layer thickness, dry;

[0053] B. Apply glass-ceramic frit: spread high-temperature transparent frit particles (purchased from Zibo Huaci Glaze Co., Ltd., 80 mesh) on the surface of the green body in step A and spray a layer of polyurethane fixing agent, and spread high-temperature transparent micro The thickness of the crystal glass frit is 2mm, and the amount of fixative is 350-500g / m2;

[0054] The component of every 100kg polyurethane fixative: nonionic polyurethane associative thickener (Nae Woi Korea., Ltd. company, model HIRESOL85) ...

Embodiment

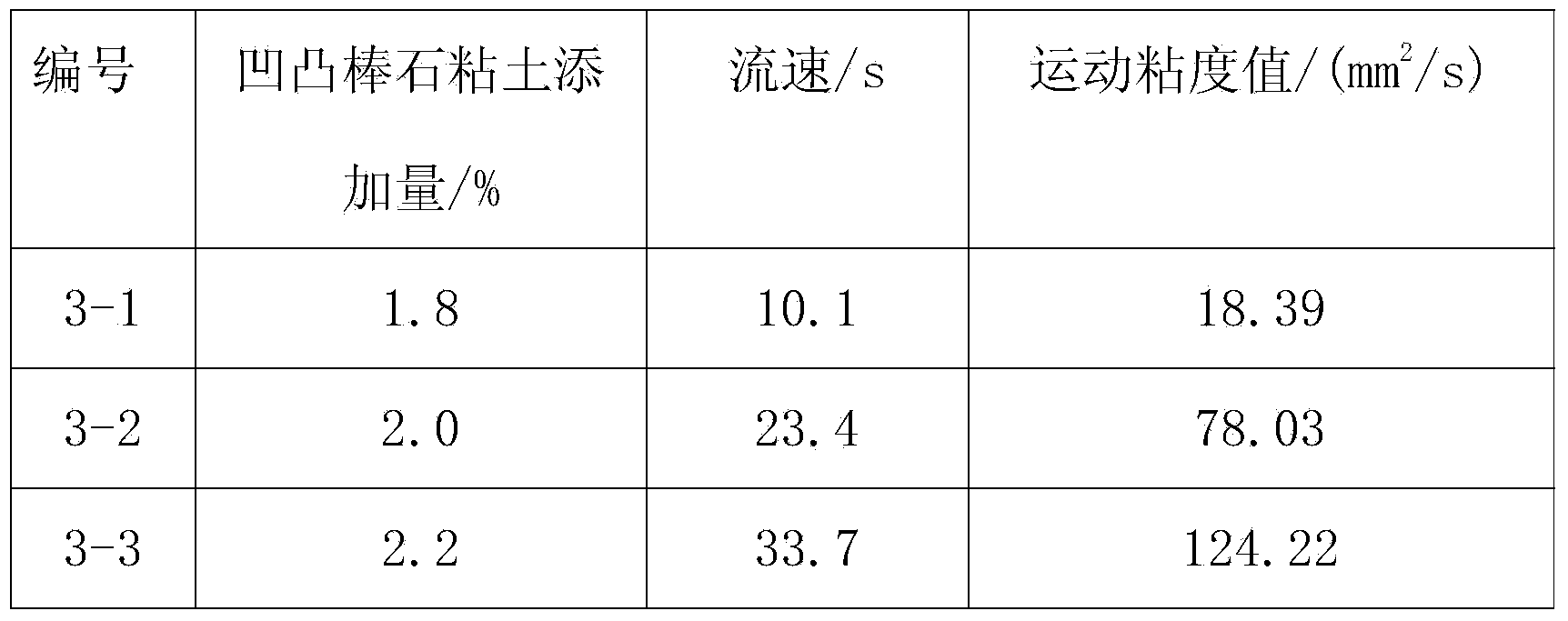

[0057] Example Group 3 - Effect of Attapulgite Clay Content on the Viscosity of Polyurethane Fixatives

[0058] The component of every 100kg polyurethane fixative: nonionic polyurethane associative thickener (Nae Woi Korea., Ltd. company, model HIRESOL85) 4.3kg, attapulgite clay content is added as follows table 2, polyether type GPE Defoamer (purchased from Hangzhou Feier Chemical Industry Co., Ltd.) 0.6kg, sodium tripolyphosphate 1.2kg, the balance is diethylene glycol ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com