A fire door core filling material and its application

A fire-proof door and core-filling technology, which is applied to fire-proof doors and other directions, can solve problems such as inconvenient handling and installation, anti-halogenation of the door core board, corrosion of steel door panels, etc., and achieves convenient handling and installation, light weight and good performance indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

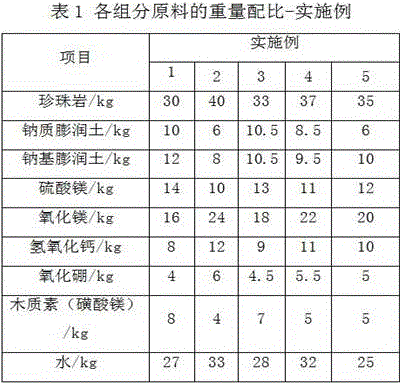

[0029] Prepare raw materials according to the weight ratio of raw materials in Table 1. Steel fire doors are manufactured in the following steps:

[0030] (1) Pour magnesium sulfate into water to melt, then pour magnesium oxide into the magnesium sulfate solution and stir evenly to obtain a mixed solution;

[0031] (2) Add the mixed solution of step (1) to it under perlite stirring;

[0032] (3) After the perlite and the mixed solution are stirred evenly, pour in boron oxide, bentonite, calcium hydroxide and lignin, and mix evenly to obtain a core material that can be used for fire door filling;

[0033] (4) Inject the core filling material obtained in step (3) into the fire door, heat it to 80°C after compaction, and keep it warm for 20 minutes, and it is ready.

[0034]

experiment example

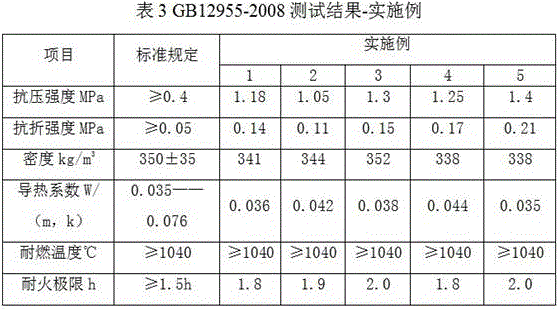

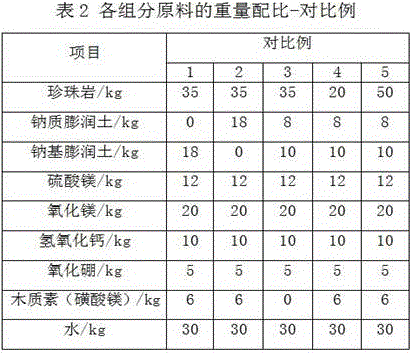

[0055] According to GB12955-2008 "New Standard for Fire Doors", the following items were tested on Examples 1-5 and Comparative Examples 1-7, and the test results are shown in Table 3-4.

[0056]

[0057]

[0058] As can be seen from Table 3, the compressive strength of the fire door filler core obtained according to the present invention is above 1MPa, the flexural strength is above 0.1MPa, and the thermal conductivity, flame-resistant temperature and fire-resistant limit all meet the standard requirements; and Table 4 shows that when changing Under the situation of component ratio and preparation process, all more or less can't meet standard requirement. Therefore, under the premise that there will be no anti-halogen in the fire door core filling material of the present invention, the components will act synergistically, so that the performance indicators of the obtained material such as compression resistance, flexural resistance, and fire resistance all meet the standar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com