High-performance microwave dielectric ceramic material and preparation method thereof

A high-performance technology of microwave dielectric ceramics, applied in the field of ceramic materials, can solve the problems of unstable price of rare earth raw materials, small dielectric constant, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

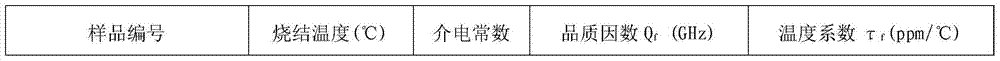

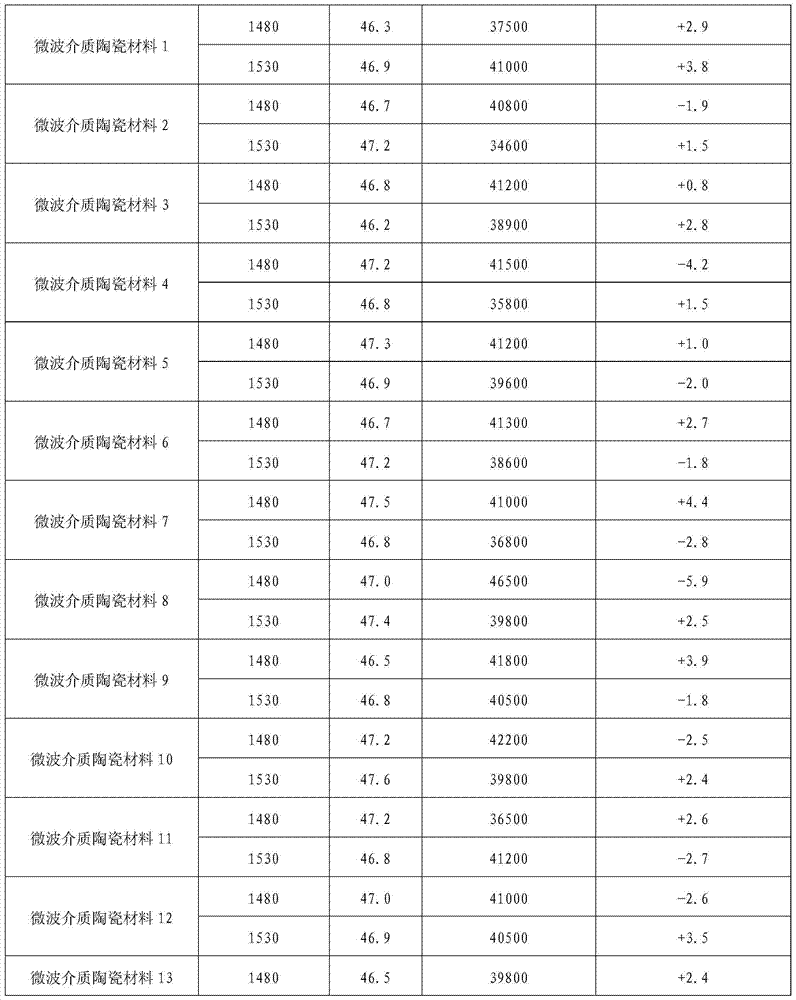

Examples

Embodiment 1

[0034] (1) Accurately weigh BaCO with a purity greater than 99.95% 3 0.11mol, CaCO 3 0.008mol, La 2 o 3 0.19mol, Sm 2 o 3 0.012mol and TiO 2 0.42mol, pour it into a resin ball mill tank, add deionized water and zirconium balls; the weight ratio of the three is: material: balls: deionized water = 1:2:1.5; ball mill in a ball mill for 24 hours to ensure uniform mixing ;After discharging, put the slurry into the oven, and dry it at 120°C to obtain the dried powder;

[0035] (2) Pass the dried powder through a 40-mesh sieve, then calcinate at 1200°C for 3 hours, and cool with the furnace to obtain a ceramic powder;

[0036] (3) Dissolve 1wt / % chemically pure zinc alkoxide (Zn) and 1.5wt / % chemically pure magnesium alkoxide (Mg) in absolute ethanol, add appropriate amount of diethanolamine and mix well, then add deionized water , through hydrolysis, polycondensation reaction, and then forming a gel to prepare nano-scale liquid phase Zn additives and Mg additives with a p...

Embodiment 2

[0040] BaCO 3 0.108mol, SrCO 3 0.008mol, La 2 o 3 0.192mol, Sm 2 o 3 0.0102mol, Pm 2 o 3 0.008mol, TiO 2 0.418 mol, 2 wt / % zinc alkoxide (Zn) and 1 wt / % nickel alkoxide (Ni). The preparation method is the same as that of Example 1, and a microwave dielectric ceramic material 2 is obtained.

Embodiment 3

[0042] BaCO 3 0.118mol, La 2 o 3 0.194mol, Eu 2 o 3 0.0122mol, TiO 2 0.420 mol, 2.5 wt / % zinc alkoxide (Zn) and 1 wt / % tin alkoxide (Sn). The preparation method is the same as that of Example 1, and a microwave dielectric ceramic material 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com