Flame-retardant polyether polyol with nitrogen structure and preparation method thereof

A flame-retardant polyether and polyol technology, applied in the field of polymer synthesis research, can solve the problems of high temperature and high pressure, high cost, etc., achieve low flammability, low smoke, and improve load-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

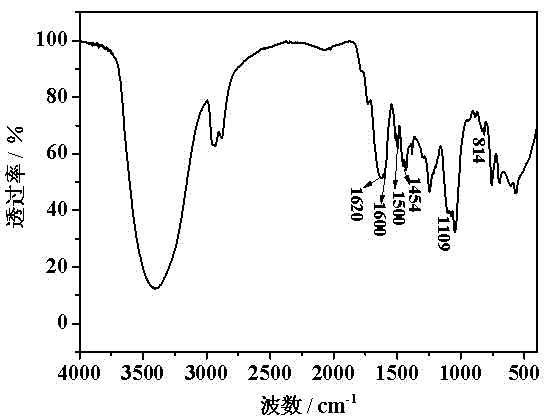

Image

Examples

Embodiment 1

[0041] A flame retardant polyether polyol with a nitrogen-containing structure, calculated in parts by weight, its raw material composition and content are as follows:

[0042] Phenol 10.0 parts

[0043] Formaldehyde 18.0 parts

[0044] Basic catalyst 0.01 part

[0045] Melamine 5.0 parts

[0046] Co-initiator 3.0 parts

[0047] Epichlorohydrin 100.0 parts

[0048] Polymerization catalyst 1.0 parts

[0049] Described formaldehyde is the formaldehyde aqueous solution that mass percent concentration is 37%;

[0050] Described alkaline catalyst is the NaOH aqueous solution that mass percent concentration is 15%;

[0051] Described co-initiator is glycerol;

[0052] The polymerization catalyst is a NaOH aqueous solution with a concentration of 30% by mass.

[0053] The preparation method of the flame-retardant polyether polyol of above-mentioned a kind of nitrogen-containing structure specifically comprises the following steps:

[0054] (1) Add phenol into a 250 mL four-n...

Embodiment 2

[0060] A flame retardant polyether polyol with a nitrogen-containing structure, calculated in parts by weight, its raw material composition and content are as follows:

[0061] Phenol 5.0 parts

[0062] Formaldehyde 15.0 parts

[0063] Basic catalyst 0.008 part

[0064] Melamine 5.0 parts

[0065] Co-initiator 2.0 parts

[0066] Epichlorohydrin 55.0 parts

[0067] Polymerization catalyst 0.5 parts

[0068] Described formaldehyde is the formaldehyde aqueous solution that mass percent concentration is 35%;

[0069] Described alkaline catalyst is the KOH aqueous solution that mass percent concentration is 20%;

[0070] Described co-initiator is triethanolamine;

[0071] The polymerization catalyst is a 40% KOH aqueous solution by mass percent.

[0072] The preparation method of the flame-retardant polyether polyol of above-mentioned a kind of nitrogen-containing structure specifically comprises the following steps:

[0073] (1) Add phenol into a 250 mL four-neck flask an...

Embodiment 3

[0079] A flame retardant polyether polyol with a nitrogen-containing structure, calculated in parts by weight, its raw material composition and content are as follows:

[0080] Phenol 20.0 parts

[0081] Formaldehyde 45.0 parts

[0082] Basic catalyst 0.02 parts

[0083] Melamine 15.0 parts

[0084] Co-initiator 5.0 parts

[0085] Epichlorohydrin 85.0 parts

[0086] Polymerization catalyst 1.6 parts

[0087] Described formaldehyde is the formaldehyde aqueous solution that mass percent concentration is 40%;

[0088] Described basic catalyst is the barium hydroxide aqueous solution that mass percent concentration is 20%;

[0089] Described co-initiator is glycerol;

[0090] The polymerization catalyst is boron trifluoride etherate complex.

[0091] The preparation method of the flame-retardant polyether polyol of above-mentioned a kind of nitrogen-containing structure specifically comprises the following steps:

[0092] (1) Add phenol into a 250 mL four-neck flask and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com