Rapid hydrophilic polyurethane light-curing adhesive, preparation method and curing method

A technology of adhesives and polyurethanes, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

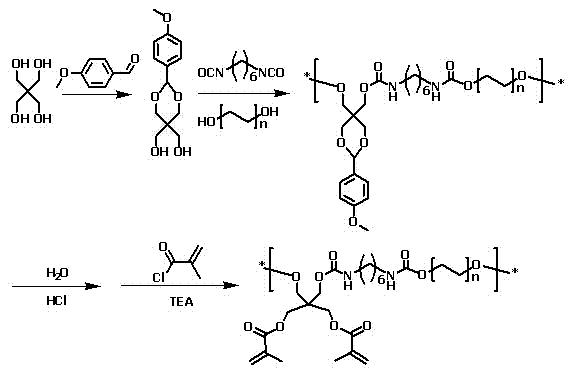

[0032] Embodiment 1: the preparation of pentaerythritol acetal

[0033] Weigh 20.0 g of pentaerythritol powder, dissolve it in 400 mL of 0.1 mol / L hydrochloric acid solution, raise the temperature to 90° C., and stir for 1 hour to obtain a pentaerythritol hydrochloric acid solution with a mass concentration of 50 mg / mL. The pentaerythritol hydrochloric acid solution was cooled to 25°C, 20.0g anisaldehyde was added dropwise, and the stirring was continued for 2h. The obtained white powder was recorded as pentaerythritol acetal, and the precipitate was washed with 1 L of distilled water, and the mass of the white solid obtained after drying was 39.0 g, and the yield was 97.5%. The resulting white powder was placed in a desiccator for later use.

Embodiment 2

[0034] Embodiment 2: Preparation of binder precursor polyurethane

[0035] Weigh 6.0 g of the pentaerythritol acetal powder obtained in Example 1, 6.0 g of polyethylene glycol (molecular weight 1 kDa), and 4.4 g of HDI were dissolved in 50 mL of 1,2-dichloroethane and 50 mL of tetrahydrofuran to obtain a mass concentration of 164 mg / mL of the reaction system solution. 0.1 g of dibutyltin dilaurate was added dropwise as a catalyst, nitrogen gas was introduced into the reaction system, and the reaction was carried out at 80° C. for 24 hours. After the reaction, the reaction system solution was cooled to 25°C, and precipitated with 600 mL of anhydrous ether to obtain a white or light yellow waxy solid, which is the binder precursor polyurethane. After drying, 15.0 g of the solid mass was obtained, and the yield was 91.5%. . The obtained white or light yellow waxy solid was placed in a desiccator for later use.

Embodiment 3

[0036] Example 3: Hydrolysis of Adhesive Precursor Polyurethane

[0037] Weigh 8.0 g of the binder precursor polyurethane obtained in Example 2, dissolve it in 100 mL of hydrochloric acid solution with a concentration of 0.1 mol / L, configure it into a polyurethane hydrochloric acid solution with a mass concentration of 80 mg / mL, and stir it with 25 ° C After 12 hours, the polyurethane was hydrolyzed to release anisaldehyde. After the reaction, neutralize the reaction system to pH=7 with 10mL NaOH aqueous solution with a concentration of 1mol / L, remove the solvent water by rotary evaporation at 5kPa and 60°C, add 100mL tetrahydrofuran to dissolve the solid (the mass concentration of polyurethane is about 60mg / mL ), filtered to remove the NaCl precipitate insoluble in tetrahydrofuran, and then precipitated with 500mL of anhydrous ether to obtain a white or light yellow waxy solid, which is hydrolyzed polyurethane. After drying, 6.0 g of solid mass was obtained, and the yield wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com