An oil shale dry distillation shale oil and gas phase state separation device

A technology for separation of shale oil, gas and phase state, applied in the field of oil shale dry distillation, can solve the problems of difficulty in ensuring the quality of shale oil, dust blockage in the condensation recovery system, and inability to remove oil and gas shale ash dust, etc., to achieve high-efficiency separation , The effect of improving quality and preventing sludge from returning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below using the accompanying drawings and examples.

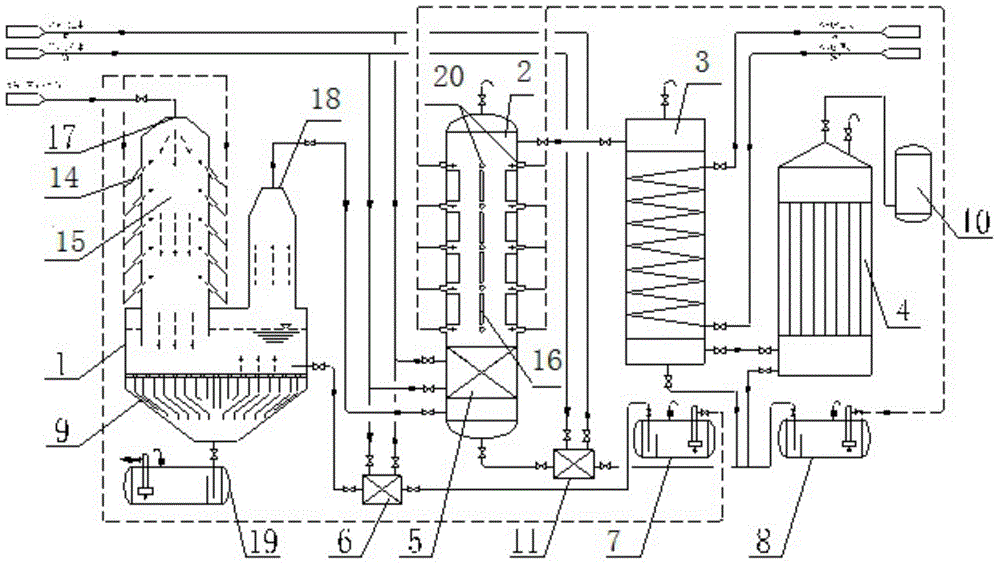

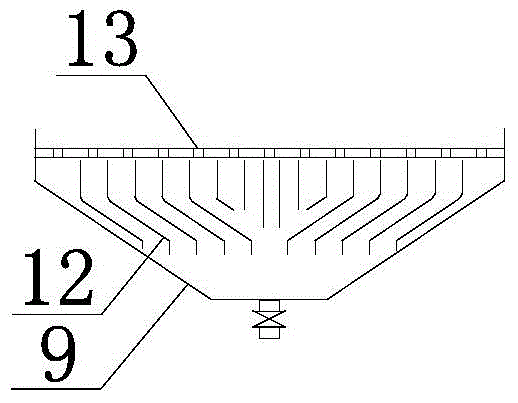

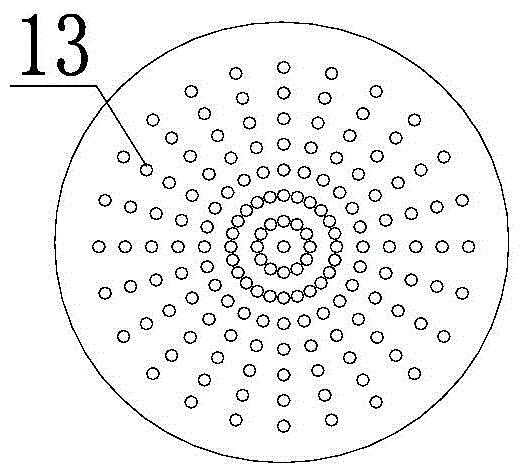

[0030] refer to Figure 1-Figure 6, a kind of oil shale dry distillation shale oil-gas phase state separation device of the present invention, comprises: heavy oil washing separation tank 1, light oil washing separation tank 2, light oil intercooling separation tank 3, electrostatic oil trap 4 , Indirect cooling heat exchanger for medium temperature 5, Indirect cooling heat exchanger for high temperature 6, Heavy oil washing circulation tank 7, Light oil washing circulation tank 8, Sludge deposition tank 9, Gas collection tank 10, Low temperature use Indirect cooling heat exchanger 11, heavy oil wash impact flow resistance body 15, light oil wash impact flow resistance body 16 and sludge tank 19. The top of the heavy oil washing separation tank 1 is provided with a high-temperature ash-containing shale oil gas inlet 17, the right side of the heavy oil washing separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com