Radio frequency identification remote cable used for base station and manufacturing method thereof

A technology of wireless radio frequency and manufacturing method, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of not fully considering the distinguishability of internal sub-cables, not fully considering the distinguishable characteristics, and not being able to play a supporting role. Avoid the effect of unstable pay-off tension, constant tension and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

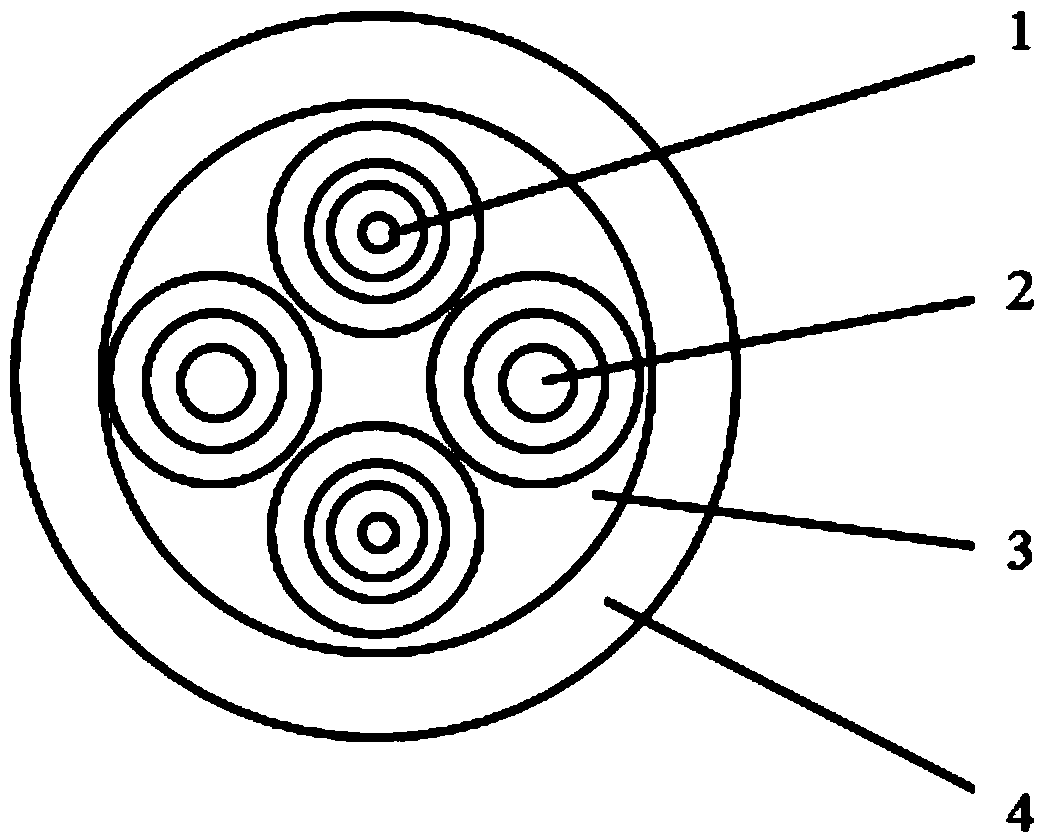

[0093] Such as figure 1 As shown, a wireless radio remote optical cable for a new base station, which includes a sub-cable 1, a filling member 2, a non-metal filling yarn 3, and a sheath 4;

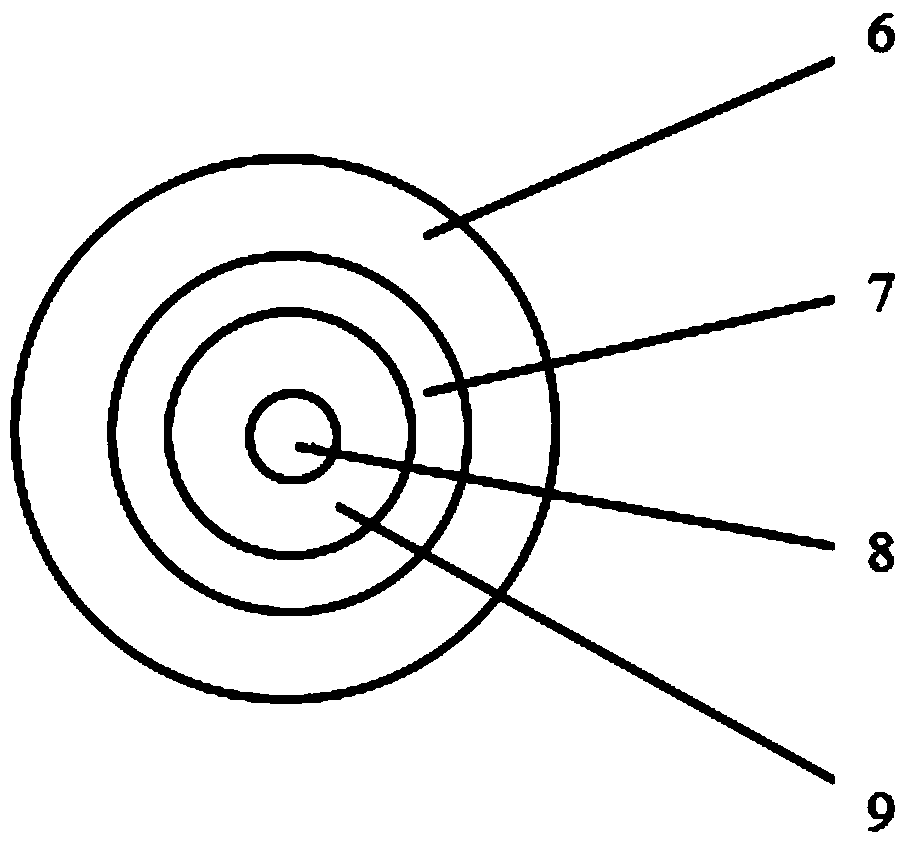

[0094] Wherein, the sub-cable is composed of an optical fiber 8, an optical fiber tight sleeve layer 9, a non-metallic reinforcing fiber yarn 7 and a sub-cable sheath 6;

[0095] Wherein, the optical fiber 8 is a B6 optical fiber specified in YD / T 1954, other single-mode optical fiber specified in GB / T 9771, or a multimode optical fiber specified in GB / T 12357.1, and the optical fiber may contain a colored and cured layer of 3 μm to 5 μm ;

[0096] Wherein, the optical fiber tight buffer layer 9 is made of thermoplastic materials such as LSZH or PVC, the outer diameter of the optical fiber tight buffer layer is 0.6mm or 0.9mm, the peeling force of the optical fiber tight buffer layer is ≤10N, and the color of the optical fiber tight buffer layer can be It is any color in the full color ...

Embodiment 2

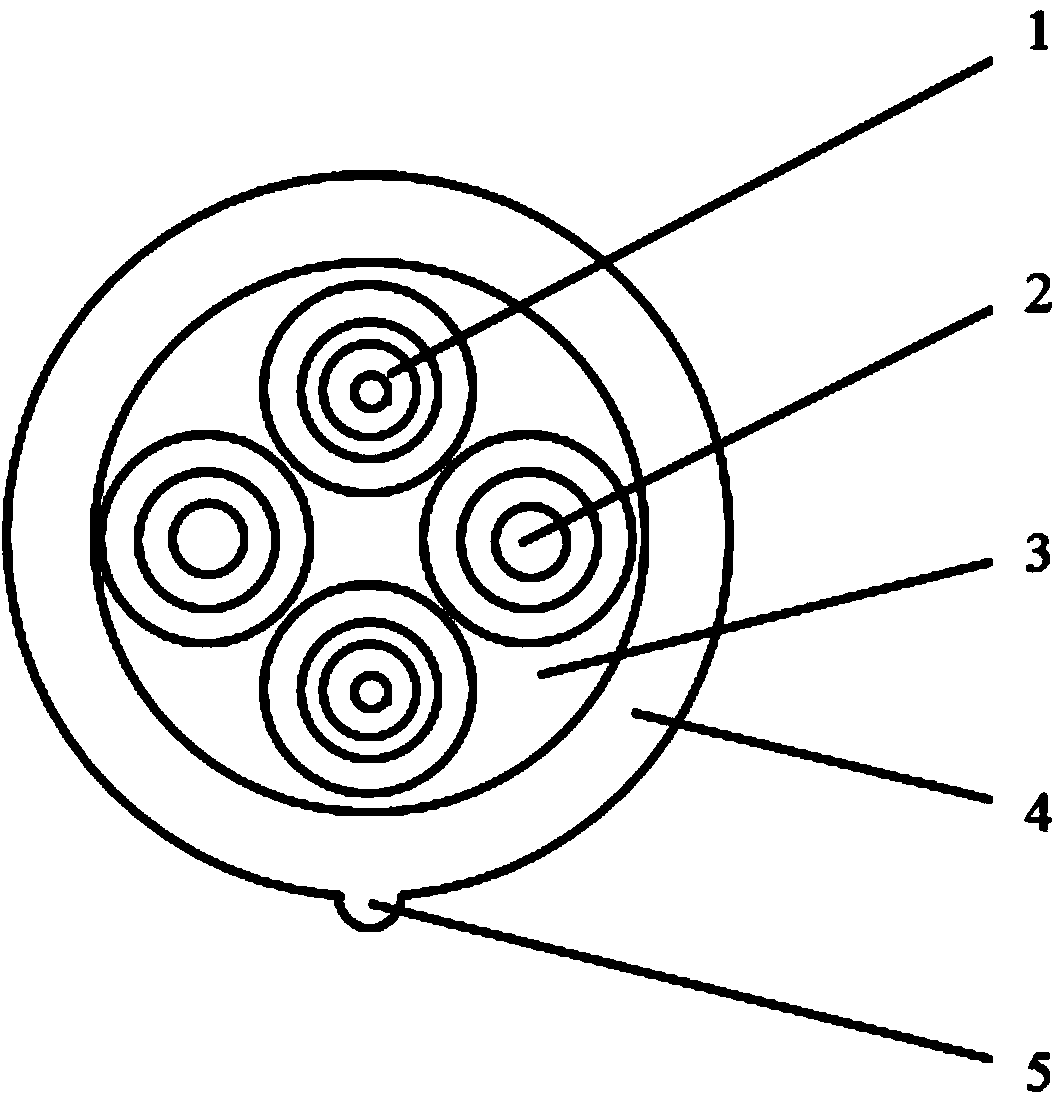

[0106] Such as figure 2 As shown, a radio frequency remote optical cable used for existing base stations. This optical cable is suitable for the construction of 3G / 4G base stations in existing 2G base stations, and can also be used for the construction of new base stations. It is different from Embodiment 1 in that the outer edge of the cylindrical sheath 4 of the optical cable is connected with a single or multiple touch identification marks 5 .

[0107] Wherein, the cylindrical sheath 4 and the touch sign 5 are produced synchronously on the machine.

[0108] Wherein, the shape of the touch mark 5 is a semicircle, a triangle or other simple shapes.

[0109] Wherein, the diameter of the semicircle is close to the outer edge of the cylindrical sheath 4, and the radius of the semicircle touch mark is 1.5mm-2.0mm.

[0110] Wherein, the bottom edge of the triangular touch mark is close to the outer edge of the cylindrical sheath 4, the apex angle of the triangular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com