Method for preparing gamma-carbonyl carboxylic acid, amino acid, amino acid ester and amide compounds

A carbonyl amino acid ester and carbonyl amino acid technology, which is applied in the field of preparation of γ-carbonyl carboxylic acid, amino acid ester and amide compounds, and amino acids, and can solve the problems of high price, limited application, difficult recovery and recycling of homogeneous catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

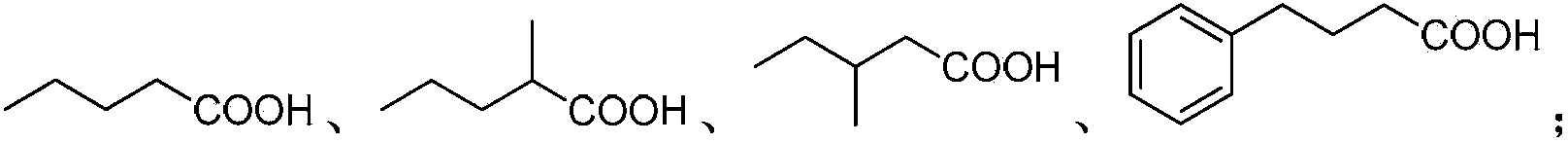

Image

Examples

Embodiment 1

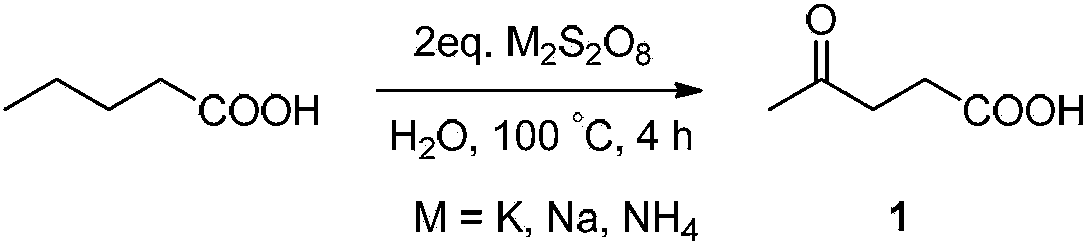

[0032] Embodiment 1, the preparation of compound 1 (method one)

[0033] The reaction equation is as follows:

[0034]

[0035] Place 1 mmol of n-valeric acid (102 mg) in a 25 mL reaction vessel with a polytetrafluoroethylene stopcock, add 2 times the amount of oxidant potassium persulfate K 2 S 2 o 8 (2mmol, 540mg), dissolved in 5mL of distilled water and heated at 100°C for 4 hours. After the reaction, the reaction system was cooled to room temperature, extracted three times by adding ethyl acetate (10 mL×3 times), and the organic phase was washed with anhydrous Na 2 SO 4 After drying, it was spin-dried and purified by column chromatography (the volume ratio of dichloromethane:methanol was 15:1). The reaction was monitored by thin-layer chromatography, visualized with bromophenol blue or CAM.

[0036] The structural confirmation data of this product are as follows:

[0037] 1 H NMR (400MHz, CDCl 3 ): δ(ppm) 2.20(s, 3H), 2.26(t, J=6.4Hz, 2H), 2.76(t, J=6.4Hz, 2H)....

Embodiment 2

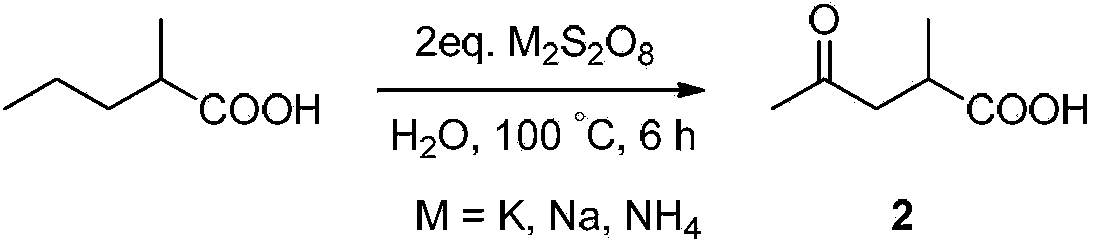

[0039] Embodiment 2, the preparation of compound 2 (method one)

[0040] The reaction equation is as follows:

[0041]

[0042] Put 1mmol of 2-methyl-n-valeric acid (116mg) in a 25mL reaction vessel with a polytetrafluoroethylene stopcock, add 2 times the amount of oxidant potassium persulfate K 2 S 2 o 8 (2mmol, 540mg), dissolved in 10mL of distilled water, and heated at 100°C for 6 hours. After the reaction, the reaction system was cooled to room temperature, extracted three times by adding ethyl acetate (10 mL×3 times), and the organic phase was washed with anhydrous Na 2 SO 4 After drying, it was spin-dried and purified by column chromatography (the volume ratio of dichloromethane:methanol was 15:1). The reaction was monitored by thin-layer chromatography, visualized with bromophenol blue or CAM.

[0043] The structural confirmation data of this product are as follows:

[0044] 1 H NMR (400MHz, CDCl 3 ): δ(ppm) 1.23(d, J=6.8Hz, 3H), 2.18(s, 3H), 2.44-2.55(m, 1H...

Embodiment 3

[0046] Embodiment 3, the preparation of compound 3 (method one)

[0047] The reaction equation is as follows:

[0048]

[0049] Put 1 mmol of 3-methyl-n-valeric acid (116 mg) in a 25 mL reaction vessel with a polytetrafluoroethylene stopcock, add 2 times the amount of oxidant potassium persulfate K 2 S 2 o 8 (2mmol, 540mg), dissolved in 10mL of distilled water, and heated at 100°C for 12 hours. After the reaction, the reaction system was cooled to room temperature, extracted three times by adding ethyl acetate (10 mL×3 times), and the organic phase was washed with anhydrous Na 2 SO 4After drying, it was spin-dried and purified by column chromatography (the volume ratio of dichloromethane:methanol was 15:1). The reaction was monitored by thin-layer chromatography, visualized with bromophenol blue or CAM.

[0050] The structural confirmation data of this product are as follows:

[0051] 1 H NMR (400MHz, CDCl 3 ): δ (ppm) 1.18 (d, J = 7.2Hz, 3H), 2.23 (s, 3H), 2.31-2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com