Preparation method of multicomponent-modified carbon-fiber-reinforced epoxy resin composite material

An epoxy resin and fiber-reinforced technology, applied in fibrous fillers, dyed organic silicon compound treatment, etc., can solve the problems of lack of controllable and effective surface activation methods, low shear strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

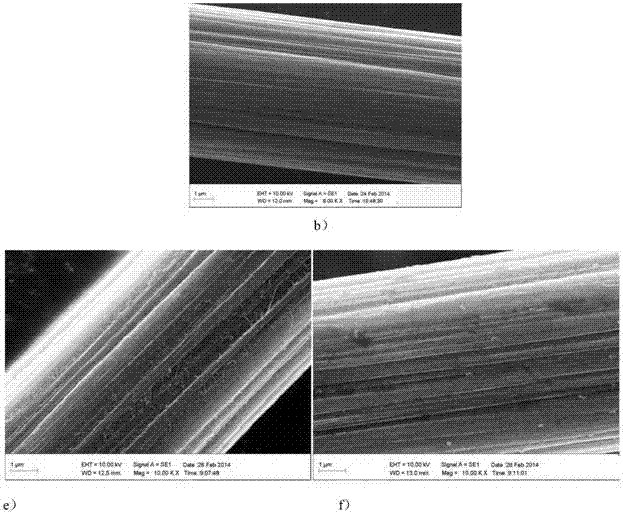

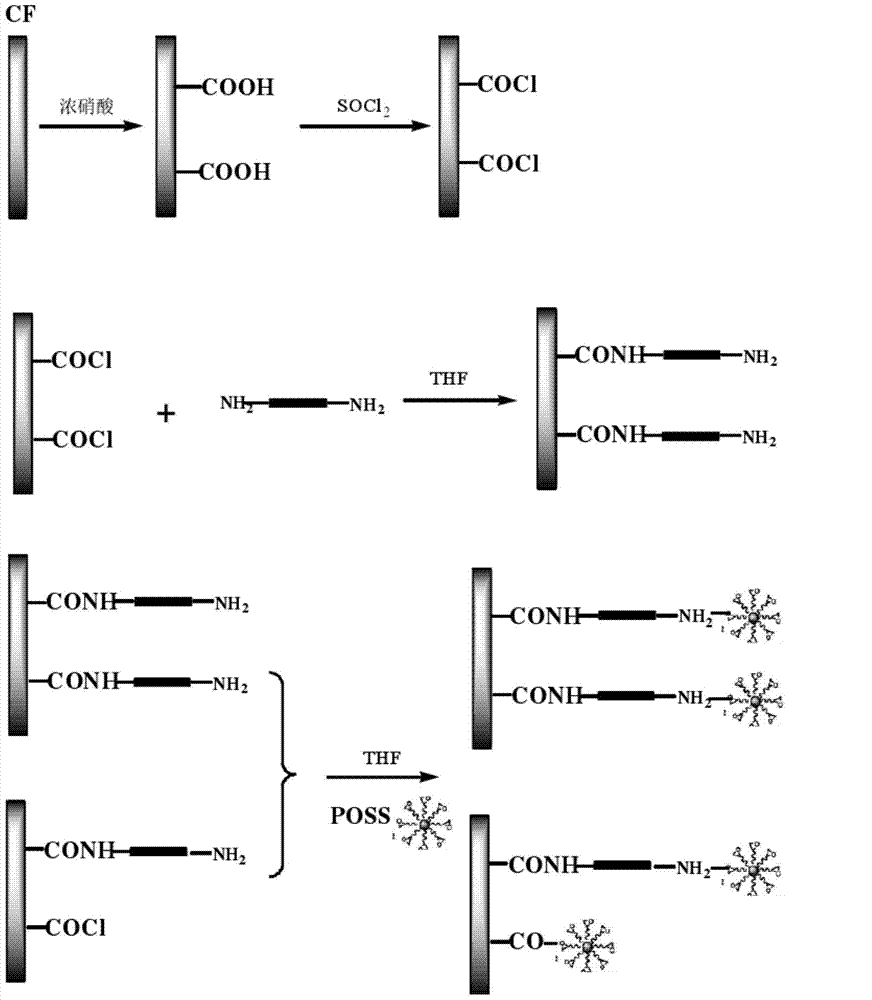

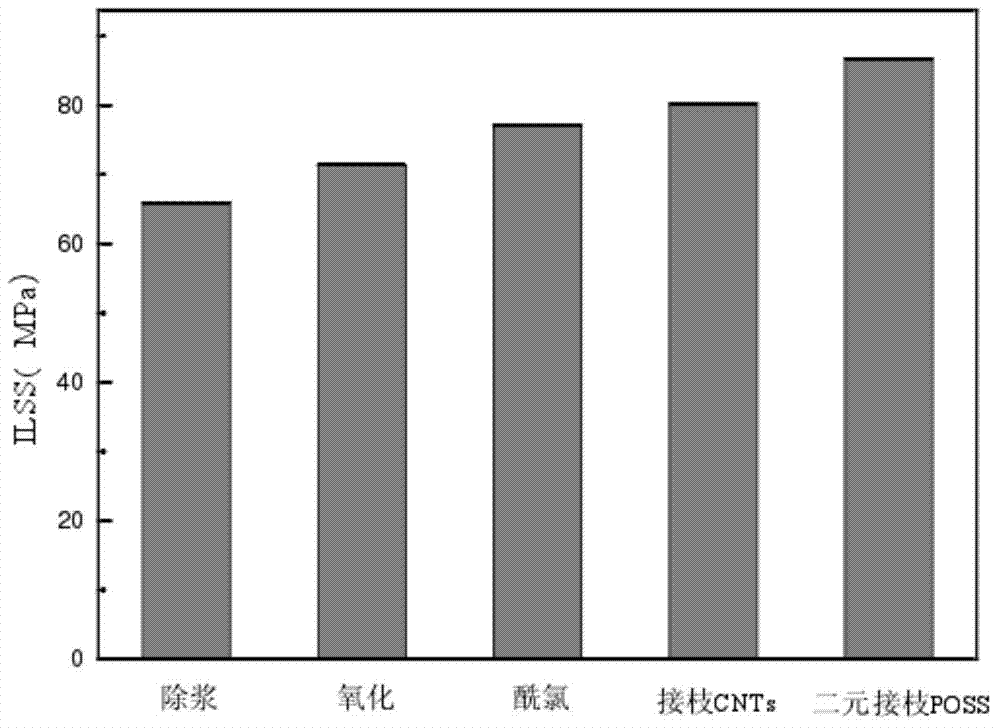

[0034] A method for preparing a multi-component modified carbon fiber reinforced epoxy resin composite material, comprising the following steps:

[0035] (1): Weigh 4g of dry CNTs into a round-bottomed flask, add 100ml of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, stir and react in a constant temperature water bath at 60°C for 4h, and the solution after reaction Add distilled water to dilute, filter with porous membrane until the washing solution is neutral, and dry under vacuum at 100°C to obtain oxidized CNTs;

[0036] (2): Add 100ml SOCl to 2g of the oxidized CNTs prepared in step (1) 2 and 5ml of N,N-dimethylformamide (DMF) solution, heated to 76°C for 72h, and then distilled off excess SOCl under reduced pressure 2 , add 100ml of ethylenediamine, heat to 80°C to react for 48h, dilute with distilled water, filter with suction until the filtrate is neutral to obtain aminated CNTs, vacuum dry at 100°C for later use;

[0037] (3): Pu...

Embodiment 2

[0048] Example 2: The difference between this example and Example 1 is that 100ml of 1,2-propylenediamine is added in step (2) to aminate the CNTs, and other steps and parameters are the same as in Example 1.

Embodiment 3

[0049] Embodiment 3: The difference between this embodiment and embodiment 1 is that 100 ml of concentrated sulfuric acid is added in step (3) to oxidize CF, and other steps and parameters are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com