Hydrogen production chlamydomonas chloroplast separation method

A technology for chloroplasts and hydrochlamydomonas, applied in the biological field, can solve problems such as difficulty in separation, and achieve the effects of time saving, high yield and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

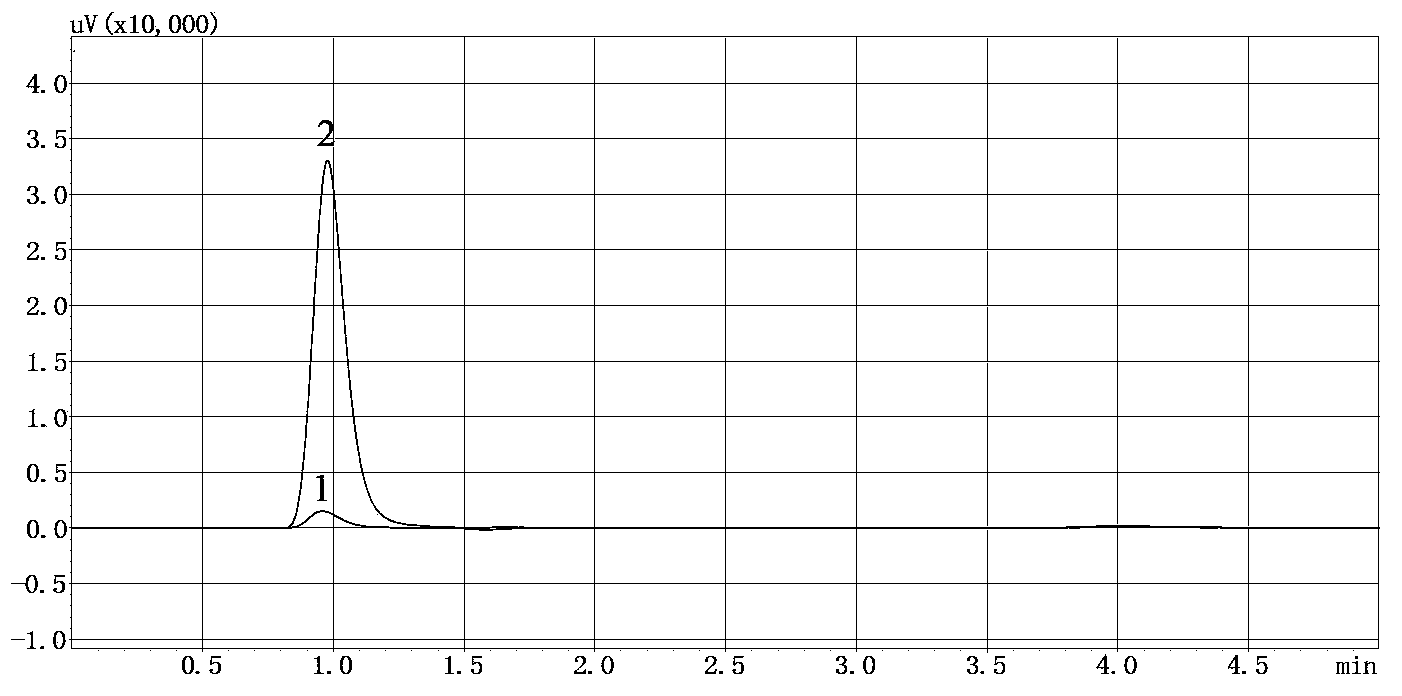

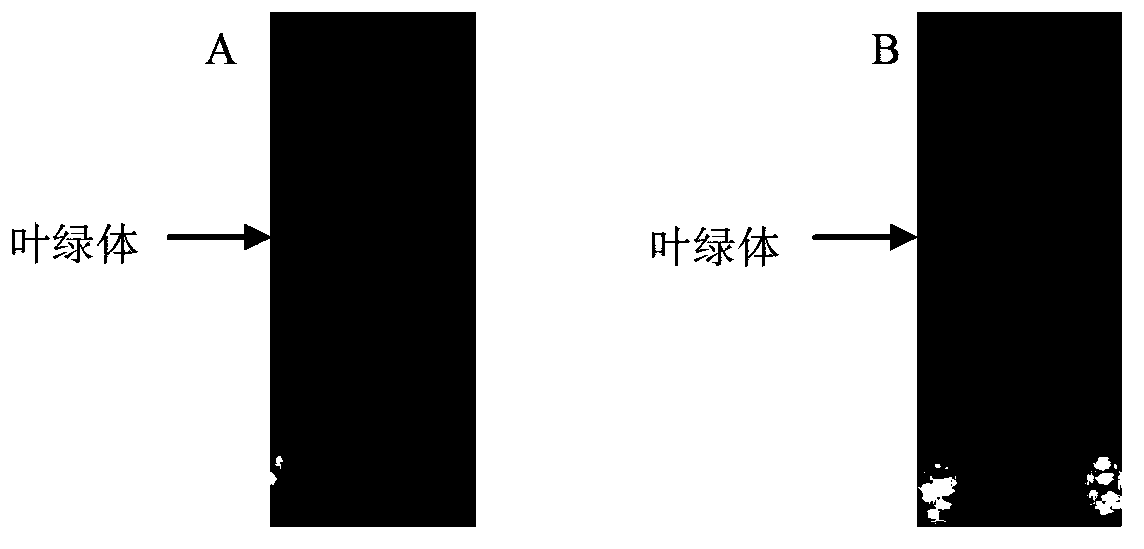

[0056] Embodiment 1, the separation of Chlamydomonas chloroplast

[0057] 1. Culture of Chlamydomonas cells

[0058] Inoculate Chlamydomonas reinhardtii (Chlamydomonas reinhardtii) CC400 into a 100ml Erlenmeyer flask containing 30ml of normal TAP culture medium at a temperature of 25°C and a light intensity of 200μE·m -2 ·s -1 Cultivate in a shaker at 60rpm under continuous light for 24-36h. Collect the pre-cultured Chlamydomonas cells and inoculate them into 900ml of normal TAP culture medium with an initial concentration of 4×10 4 pcs / ml (OD 750 about 0.02); at a temperature of 25°C, the light intensity is 120μE·m -2 ·s -1 Under the conditions, the synchronous culture of "12h light: 12h dark" was carried out, co-cultured for 3 photoperiods, and Chlamydomonas cells were collected at 4-6h of the fourth photoperiod.

[0059] 2. Sulfur deficiency treatment induces hydrogen production reaction

[0060] 1. Centrifuge at 2500 rpm for 4 minutes at 25°C to collect the Chlamydo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com