Lithium-manganese composite oxide in which size of vertical angle of primary particle is adjusted, and method for preparing same

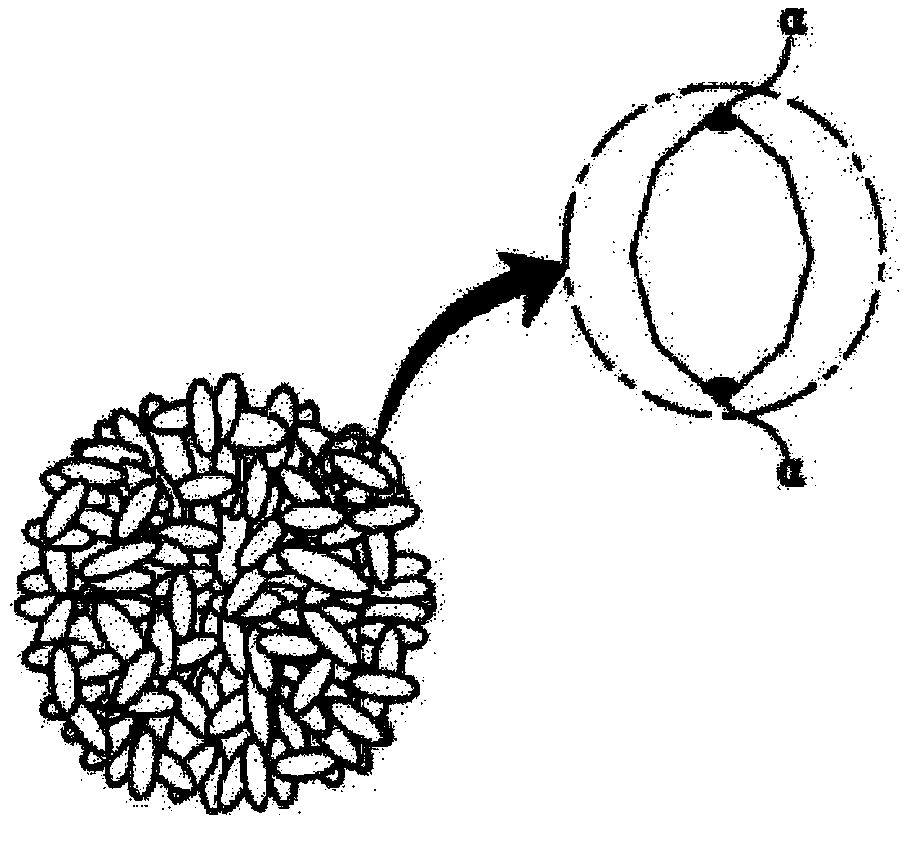

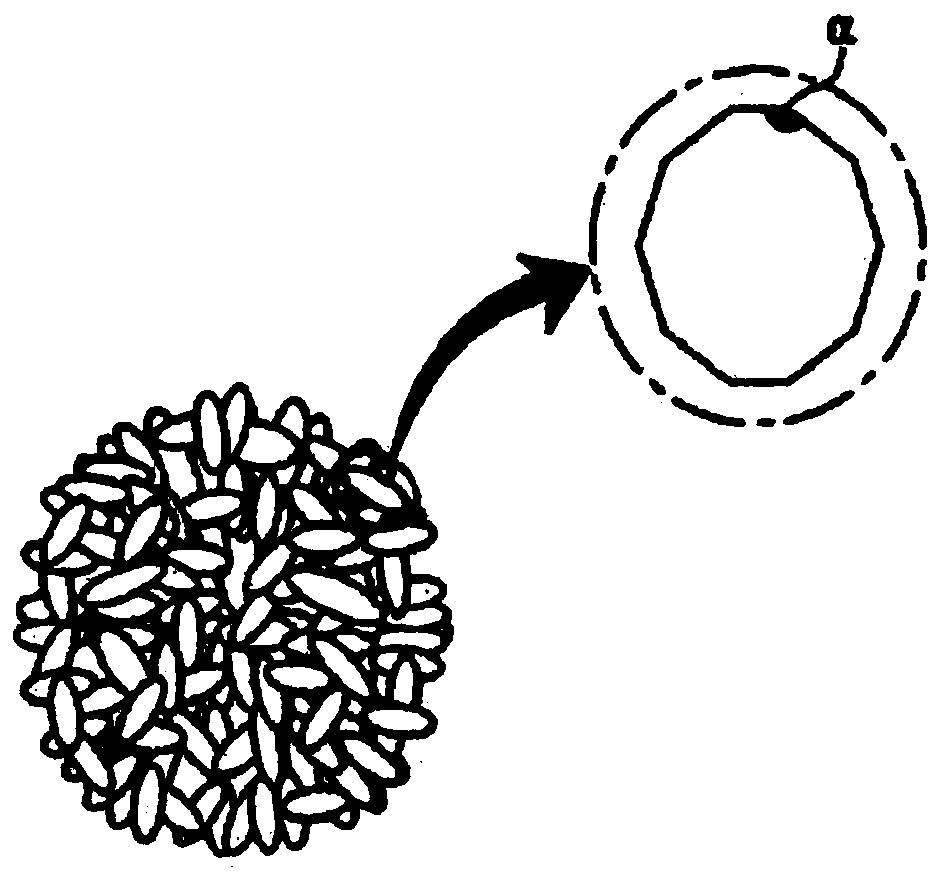

A composite oxide, apex angle technology, applied in manganese compounds, lithium compounds, chemical instruments and methods, etc., can solve the problems of different surface resistance according to position, temperature rise, battery resistance increase, etc., to achieve the effect of improving battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

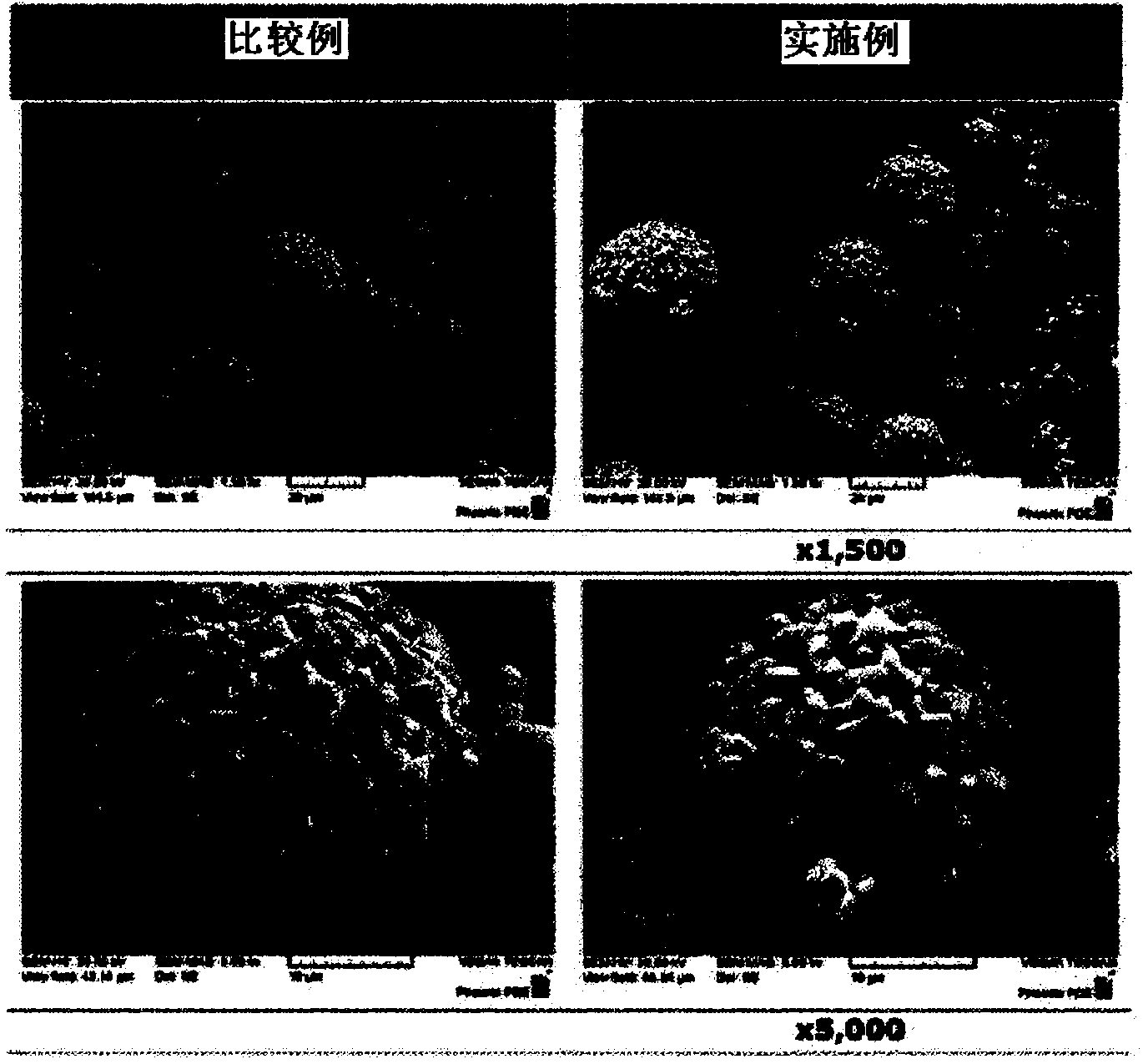

[0046] Measurement of SEM image

[0047] Measure the SEM images of the lithium-manganese composite oxides prepared in the above-mentioned examples and comparative examples respectively, and the results are shown in image 3 middle.

[0048] Such as image 3 As shown, it can be seen that the apex angles of the lithium-manganese composite oxides produced in the examples of the present invention are rounded.

Embodiment 2

[0049] Measurement of Vertex Angle

[0050] With respect to the lithium-manganese composite oxide secondary particles prepared in the above-mentioned examples and comparative examples, 10 primary particles were randomly selected, and the diagonal angles of the polygons constituting the primary particles were respectively measured, and the results are shown in Table 1 below middle.

[0051] Table 1

[0052] [Table1]

[0053]

Example

comparative example

1

101°

60°

2

103°

72°

3

108°

65°

4

98°

67°

[0054] 5

96°

59°

6

100°

73°

7

102°

82°

8

95°

69°

9

110°

72°

10

112°

73°

[0055] It can be seen from the above Table 1 that, for the lithium-manganese composite oxide secondary particles prepared according to the examples of the present invention, the magnitude of the opposite apex angle of the pol...

Embodiment 3

[0060] Measurement of life characteristics

[0061] The above-mentioned charging and discharging were carried out at room temperature and high temperature (45°C) for 80 cycles, and the discharge capacity was measured to measure the life characteristics. The results are shown in Figure 5 , Figure 6 middle.

[0062] From Figure 5 , Figure 6 It can be seen from the figure that the capacity of the lithium manganese composite oxide prepared according to the present invention is improved and kept constant at room temperature and high temperature (45°C) compared with the comparative example, so that the life characteristics are improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com