Preparation method of pilose antler pure powder

A pure velvet powder and velvet technology, applied in the field of preparation of pure velvet powder, can solve the unresolved problems of velvet freeze-dried powder, shorten the processing cycle of velvet, improve physiological activity and use value, facilitate human body absorption, and facilitate consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

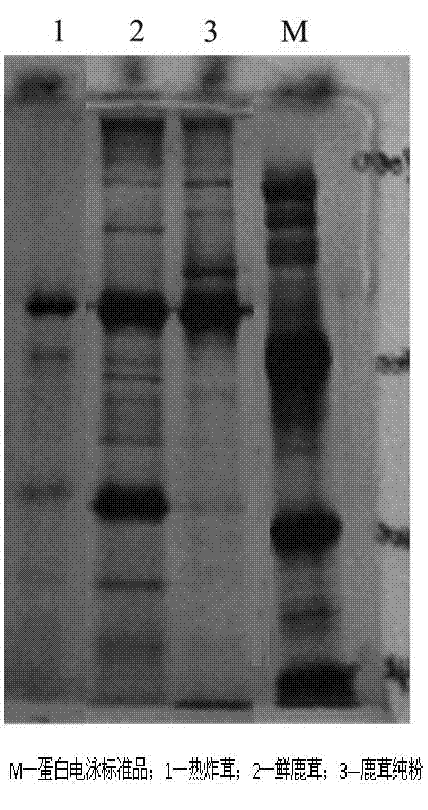

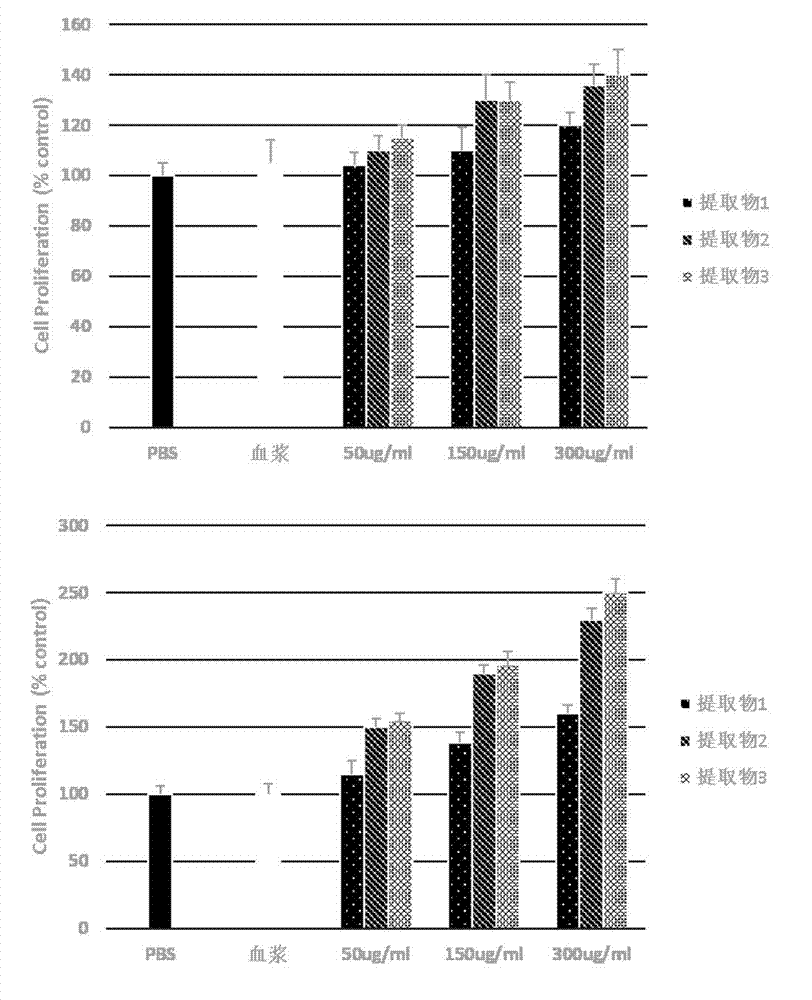

Image

Examples

Embodiment 1

[0016] 1) Cleaning process: under the condition of not damaging the appearance of raw materials, use 40 o Wash the deer antler with 2% alkaline water of about C.

[0017] 2) Peeling process: Take out the frozen velvet antler and burn it with an alcohol lamp to remove the hair, then scrape off the ashes of the velvet with a knife, and tear off the antler skin along the fiber direction of the velvet.

[0018] 3) Slicing process: proceed quickly at 4°C, and pick slices with a metal plate in an ice bath state, with a slice thickness of 1-6 mm.

[0019] 4) Freeze-drying process: first pre-cool the freeze-dryer to -56°C, then put the velvet slices that have been frozen at -30°C for 0.5 hours on the shelf of the freeze-dryer, and turn on the vacuum pump to make the freeze-dryer dry. The internal pressure drops. In the sublimation stage, the pressure is maintained at about 50Pa, and the temperature is continuously raised from -20°C to 0°C and kept constant for about 6 hours. The pr...

Embodiment 2

[0022] Cleaning, peeling, slicing and crushing process are the same as in Example 1, and the freeze-drying process of the present embodiment is:

[0023] Pre-cool the lyophilizer to -30°C, then put the antler slices that have been frozen at -40°C for 0.5 hours on the shelf of the lyophilizer, and turn on the vacuum pump to reduce the pressure in the lyophilizer. In the sublimation stage, the pressure is maintained at about 80Pa, and the temperature is continuously raised from -20°C to 0°C and kept constant for about 4 hours. The pressure in the desorption stage is maintained at about 50Pa, and the temperature rises from 10°C to 40°C and remains constant for about 3 hours.

Embodiment 3

[0025] Cleaning, peeling, slicing and crushing process are the same as in Example 1, and the freeze-drying process of the present embodiment is:

[0026] Pre-cool the lyophilizer to -45°C, then put the antler slices that have been frozen at -20°C for 1.5 hours on the shelf of the lyophilizer, and turn on the vacuum pump to reduce the pressure in the lyophilizer. In the sublimation stage, the pressure is maintained at about 60Pa, and the temperature is continuously raised from -20°C to 0°C and kept constant for about 5 hours. The pressure in the desorption stage is maintained at about 60Pa, and the temperature rises from 20°C to 40°C and remains constant for about 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com