Preparation method for compound radix isatidis granules

A technology of compound banlan and granules, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, plant raw materials, etc., can solve the problems of effective ingredient wrapping precipitation yield, large amount of ethanol, difficult problems, etc., to achieve process optimization, Effect of reducing ethanol concentration and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

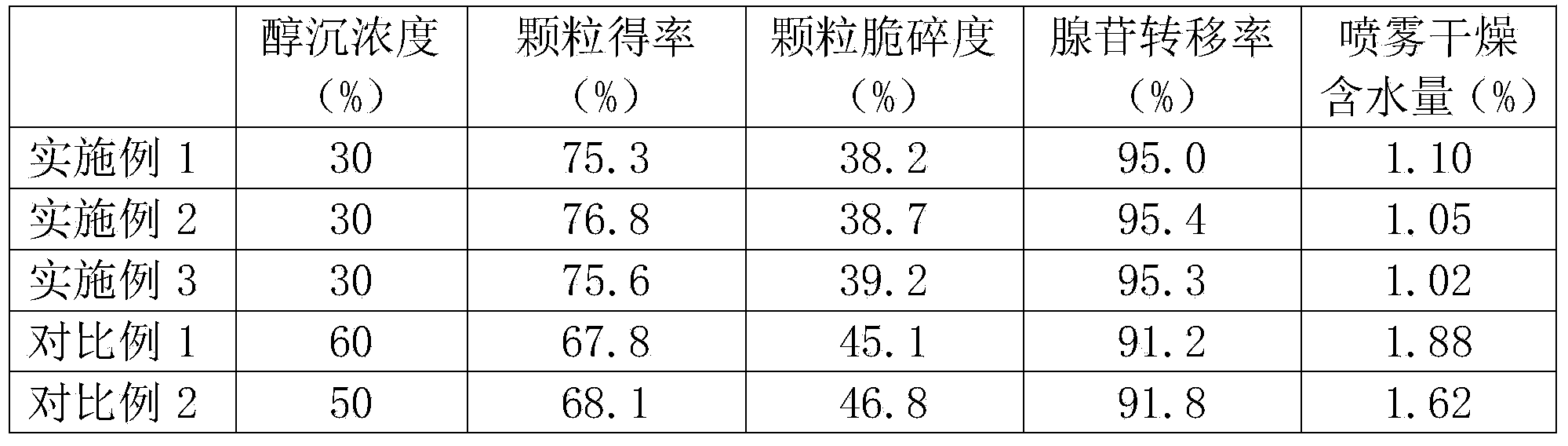

Examples

Embodiment 1

[0020] 1) Decoct the Radix isatidis raw material with water for two times, the first time for 2 hours, the second time for 1 hour, combine the decoction, and filter;

[0021] 2) The filtrate is concentrated to a relative density of 1.10, and the temperature is 45° C., adding a compound enzyme composed of pectinase, cellulase, and pectin lyase for enzymolysis, and the weight of pectinase, cellulase, and pectin lyase is The ratio is 5:3:2, and the compound enzyme addition is 0.5% of the concentrated filtrate weight;

[0022] 3) Continue to concentrate until the relative density is 1.20, the temperature is 45°C, filter, cool, add 95% ethanol to make the alcohol content 30%, static precipitation, and extract the supernatant;

[0023] 4) Recover ethanol and concentrate it to a relative density of 1.20 at a temperature of 70°C;

[0024] 5) Add conventional amounts of sucrose and dextrin to make granules and dry.

Embodiment 2

[0026] 1) Decoct the Radix isatidis raw material with water for two times, the first time for 2 hours, the second time for 1 hour, combine the decoction, and filter;

[0027] 2) The filtrate is concentrated to a relative density of 1.10, and the temperature is 45° C., adding a compound enzyme composed of pectinase, cellulase, and pectin lyase for enzymolysis, and the weight of pectinase, cellulase, and pectin lyase is The ratio is 5:3:2, and the compound enzyme addition is 1.0% of the concentrated filtrate weight;

[0028] 3) Continue to concentrate until the relative density is 1.20, the temperature is 45°C, filter, cool, add 95% ethanol to make the alcohol content 30%, static precipitation, and extract the supernatant;

[0029] 4) Recover ethanol and concentrate it to a relative density of 1.20 at a temperature of 70°C;

[0030] 5) Add conventional amounts of sucrose and dextrin to make granules and dry.

Embodiment 3

[0032] 1) Decoct the Radix isatidis raw material with water for two times, the first time for 2 hours, the second time for 1 hour, combine the decoction, and filter;

[0033] 2) The filtrate is concentrated to a relative density of 1.10, and the temperature is 45° C., adding a compound enzyme composed of pectinase, cellulase, and pectin lyase for enzymolysis, and the weight of pectinase, cellulase, and pectin lyase is The ratio is 5:3:2, and the compound enzyme addition is 0.8% of the concentrated filtrate weight;

[0034] 3) Continue to concentrate until the relative density is 1.20, the temperature is 45°C, filter, cool, add 95% ethanol to make the alcohol content 30%, static precipitation, and extract the supernatant;

[0035] 4) Recover ethanol and concentrate it to a relative density of 1.20 at a temperature of 70°C;

[0036] 5) Add conventional amounts of sucrose and dextrin to make granules and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com