Method for recovering sodium chloride and glycerin from glycerin-containing high-salinity organic wastewater

A technology of organic waste water and recovery methods, applied in chemical instruments and methods, alkali metal chlorides, water pollutants, etc., can solve problems such as waste of resources, pollution of the environment, and non-recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

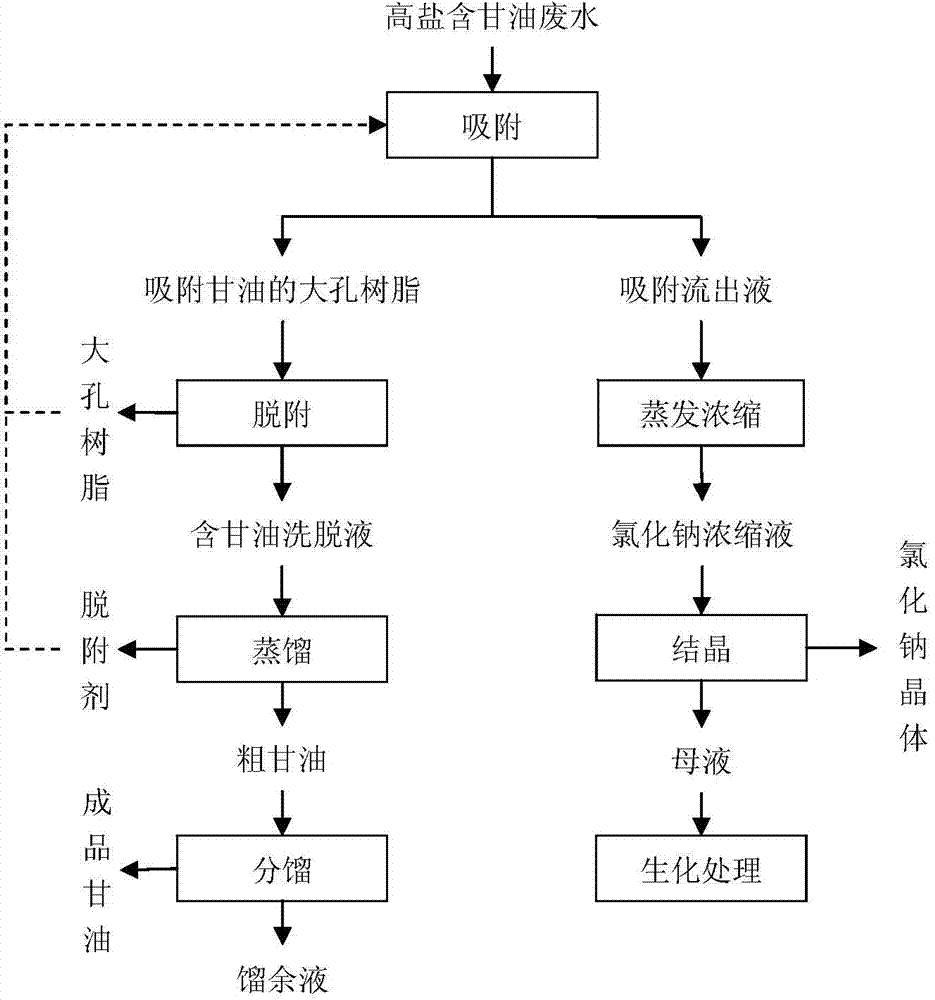

Method used

Image

Examples

Embodiment 1

[0038] Sodium chloride and glycerin were used to prepare a solution with a certain concentration to simulate wastewater. The quality of wastewater is shown in Table 1.

[0039] Table 1 Water quality of simulated wastewater

[0040] name

COD (ppm)

Glycerin (%)

Sodium chloride(%)

simulated wastewater

60908

121380

10.0

20.0

[0041] (1) Adsorption

[0042] The contents of sodium chloride and glycerin in the simulated waste water are 20% and 10% respectively. After adsorption by macroporous resin, the contents of sodium chloride and glycerin in the raffinate are 19.2% and 0.4% respectively, which shows that most of the glycerin adsorption On the macroporous resin, the separation of glycerin and sodium chloride is realized.

[0043] (2) Evaporation and concentration

[0044] The sodium chloride-containing effluent obtained by the adsorption in the step (1) flows into the evaporator through a pipeline, and...

Embodiment 2

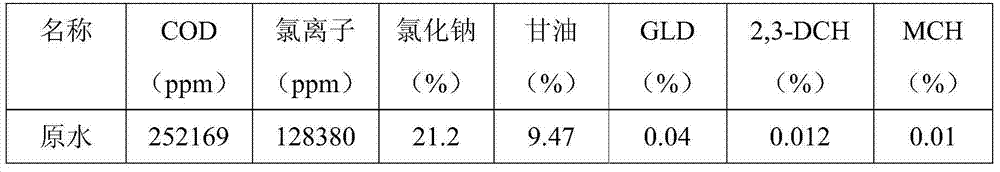

[0063] The raw water quality of petrochemical wastewater in a chemical plant is shown in Table 4.

[0064] Table 4 Experimental results of petrochemical wastewater

[0065]

[0066] (1) Adsorption

[0067] The contents of sodium chloride, glycerin, GLD, 2,3-DCH, and MCH in the raw water of petrochemical wastewater are 21.2%, 9.47%, 0.04%, 0.012%, and 0.01%, respectively. The contents of sodium, glycerin, GLD, 2,3-DCH, and MCH are 20.1%, 0.25%, 0.01%, 0.003%, and 0.002%, respectively, which shows that most of the organic substances such as glycerin, GLD, 2,3-DCH, and MCH Adsorbed on the macroporous resin to realize the separation of organic matter and sodium chloride.

[0068] (2) Evaporation and concentration

[0069] The sodium chloride-containing effluent obtained by the adsorption in the step (1) flows into the evaporator through a pipeline, and the sodium chloride-containing effluent is evaporated and concentrated to obtain a sodium chloride concentrate.

[0070] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com