A kind of preparation method of environment-friendly semi-organic insulating coating for high silicon steel

A technology of insulating coating and high-silicon steel, which is applied in coatings, devices for coating liquid on the surface, anti-corrosion coatings, etc., can solve problems such as environmental pollution of chromium elements, achieve good comprehensive performance, solve environmental pollution problems, and good welding The effect of sex and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

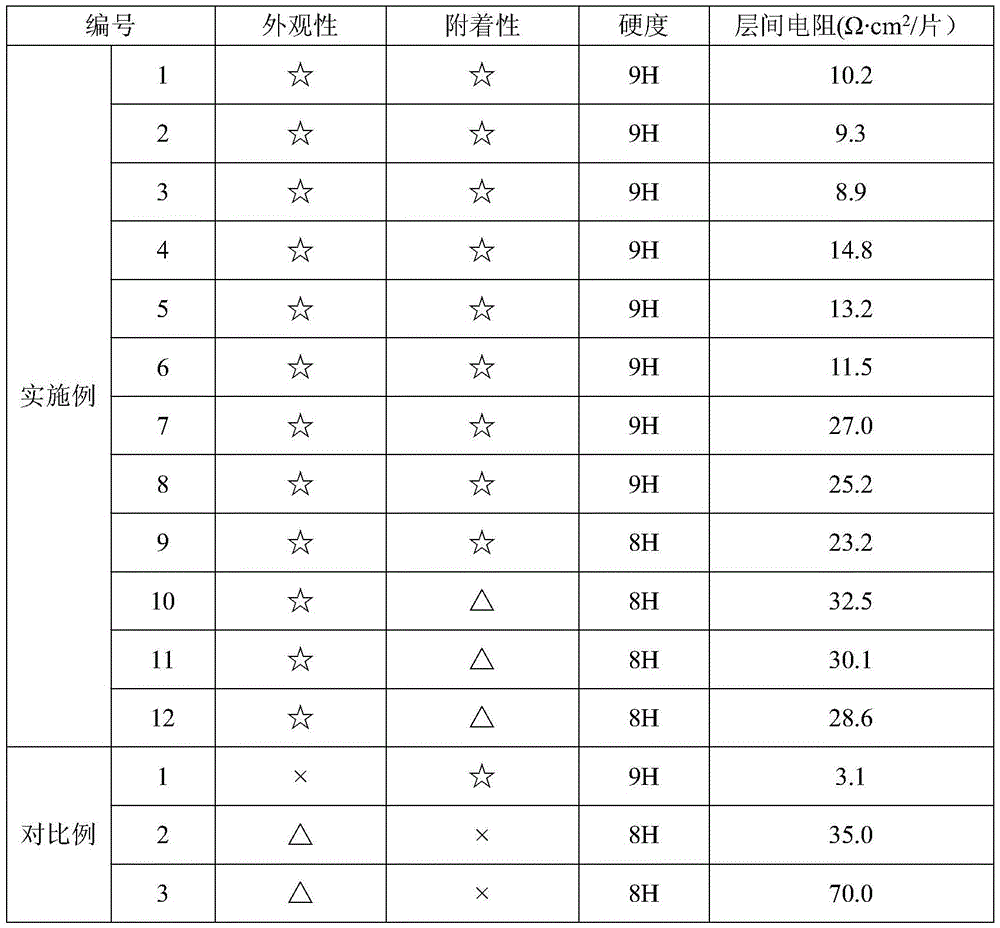

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the protection scope of the present invention.

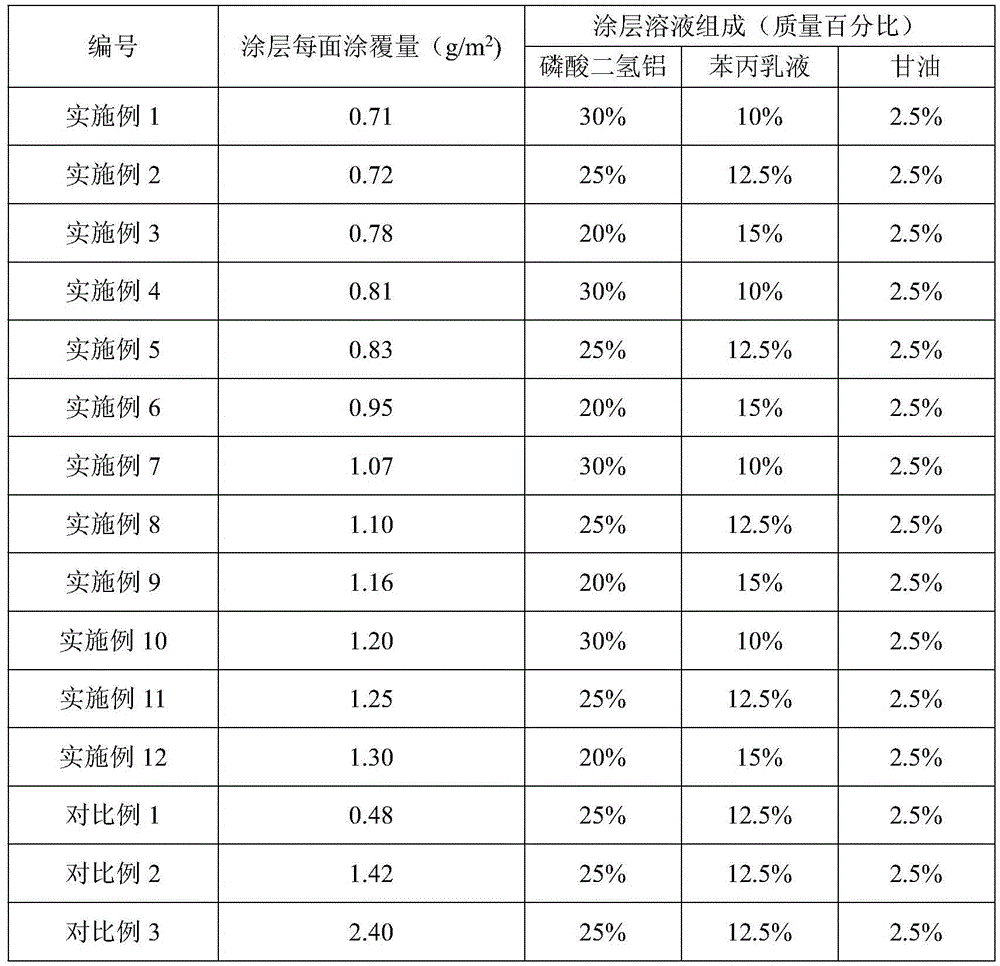

[0019] The surface of the high silicon steel (6.5% silicon content) after annealing of the finished product is first pickled with 5% to 10% phosphoric acid solution, and then polished with a nylon brush to remove impurities such as surface oxides and element enrichment layers. After 3% to 5% Pickling with hydrofluoric acid solution to make SiO 2 The layer is loose and exposes the metal matrix, washed with water and dried. The concentrations of the above acid solutions are all in mass percentages. The surface quality after treatment is shown in Table 1.

[0020] Table 1 Surface quality of high silicon steel after pretreatment

[0021] Numbering

Phosphoric acid solution (mass percent)

Hydrofl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com