A method for preparing the surface of water-repellent and oil-repellent superphobic fabric

A water- and oil-repellent, super-hydrophobic technology, which is used in textiles, papermaking, and fiber processing. The effect of controllable properties and molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing a surface of a water- and oil-repellent superphobic fabric, comprising the following steps:

[0032] (1) Weigh cotton fabrics, and prepare cotton cellulose macromolecular initiators under the action of initiators and catalysts;

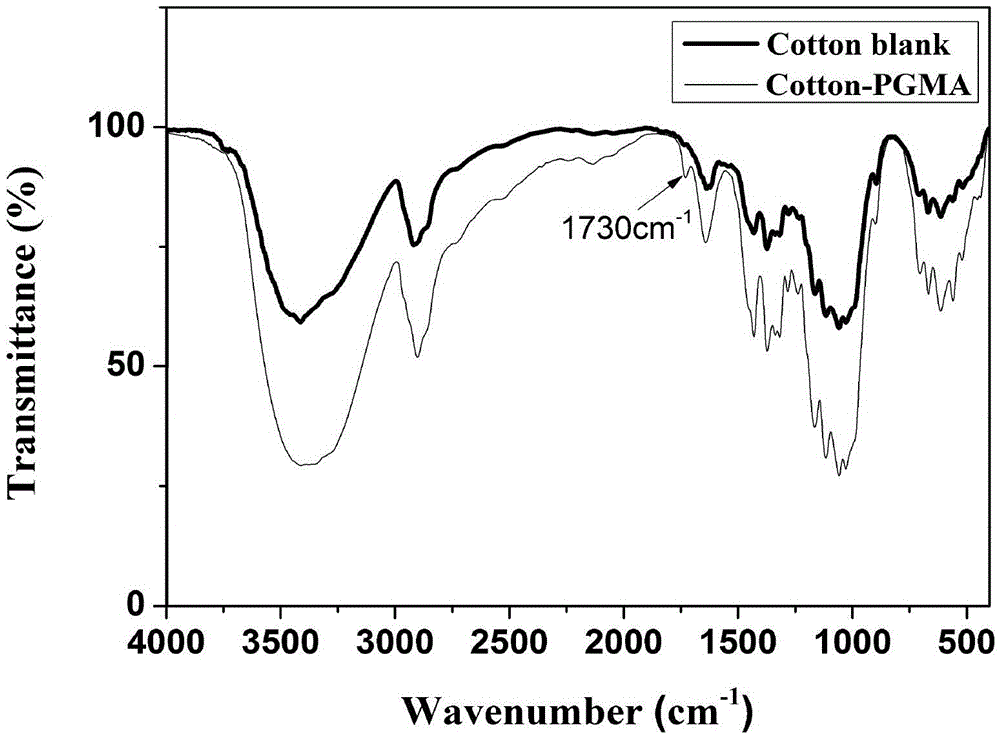

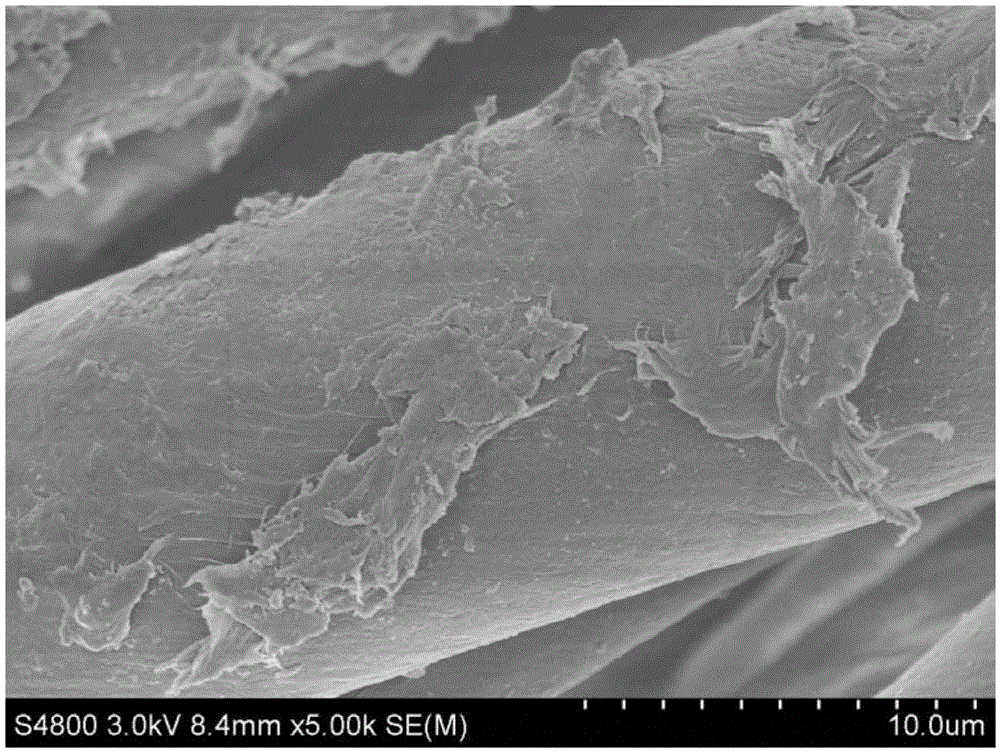

[0033] (2) graft monomer GMA on the cotton cellulose macroinitiator prepared above, the reaction system is evacuated and fed with nitrogen to obtain the cotton cellulose of the grafted GMA, and the cotton cellulose of the obtained grafted GMA is soaked in acid In solution, the epoxy groups thereon undergo hydrolysis to form a hydroxyl-rich cellulose surface; and

[0034] (3) acylation reaction of GMA-grafted cotton cellulose on the surface of the hydroxyl-rich cellulose prepared above and low-carbon fluoride heptafluorobutyryl chloride or long-chain siloxane compound to obtain water- and oil-repellent superphobicity surface.

[0035]In order to make the above objects, features and advantag...

Embodiment 1

[0052] This embodiment prepares a water- and oil-repellent superphobic surface according to the following steps:

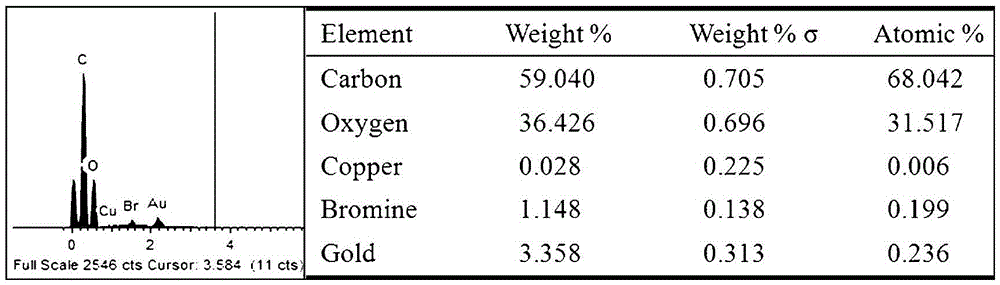

[0053] The first step, the preparation of cotton cellulose macroinitiator

[0054] The pretreatment of cotton fabrics in the experiment included soaping, ethanol ultrasonic cleaning for 20 min, THF ultrasonic cleaning for 10 min, and drying and cooling at low temperature for use. Weigh about 1g of cotton fabric, calculate the amount of each reagent according to the mass ratio m (cotton: 2-bromoisobutyryl bromide: DMAP: triethylamine) = 1:2:0.5:0.9, add 50ml THF to the round bottom flask, Then DMAP and triethylamine were added, the round-bottomed flask was cooled to 10°C in an ice bath, the initiator 2-bromoisobutyryl bromide was added dropwise, the cotton fabric was added, and the temperature was raised to 30°C after 1 h of reaction to continue The reaction was carried out for 24h, and the whole reaction was carried out under the stirring of a magnetic rotor. Af...

Embodiment 2

[0060] This embodiment prepares a water- and oil-repellent superphobic surface according to the following steps:

[0061] The first step, the preparation of cotton cellulose macroinitiator

[0062] The pretreatment of cotton fabrics in the experiment included soaping, ethanol ultrasonic cleaning for 20 min, THF ultrasonic cleaning for 10 min, and drying and cooling at low temperature for use. Weigh about 1g of cotton fabric, calculate the amount of each reagent according to the mass ratio m (cotton: 2-bromoisobutyryl bromide: DMAP: triethylamine) = 1:2:0.5:0.9, add 50ml THF to the round bottom flask, Then DMAP and triethylamine were added, the round-bottomed flask was cooled to 10°C in an ice bath, the initiator 2-bromoisobutyryl bromide was added dropwise, the cotton fabric was added, and the temperature was raised to 30°C after 1 h of reaction to continue The reaction was carried out for 24h, and the whole reaction was carried out under the stirring of a magnetic rotor. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com