High-elasto-viscosity stress absorbing layer and top facing construction process thereof

A technology of viscous stress and construction technology, which is applied to the direction of cohesive pavement paved on site, buildings, roads, etc., can solve the problems of reducing weight, reducing road surface use function, increasing engineering cost, etc., achieving strong stress absorption capacity, anti-corrosion Improved rutting ability and increased overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In order to fill the gaps in the cement concrete overlay in our country, this embodiment provides a high elastic-viscosity stress absorbing layer, which is arranged between the old cement concrete pavement and the overlay layer above it, and the absorbing layer is composed of cementitious materials and mineral materials The mixture, the cementing material is polymer modified asphalt, the mineral material includes aggregate and mineral powder, the aggregate includes coarse aggregate and fine aggregate, the coarse aggregate is limestone, and the fine aggregate It is fine river sand, and the mineral powder is crushed limestone; the mass proportion of each component of the mineral material is 20% of limestone, 30% of fine sand, 45% of stone dust (components of sieve <2.36), ore 5% powder, and the amount of polymer modified asphalt is 8.1-9.6% of the mass of the mineral aggregate.

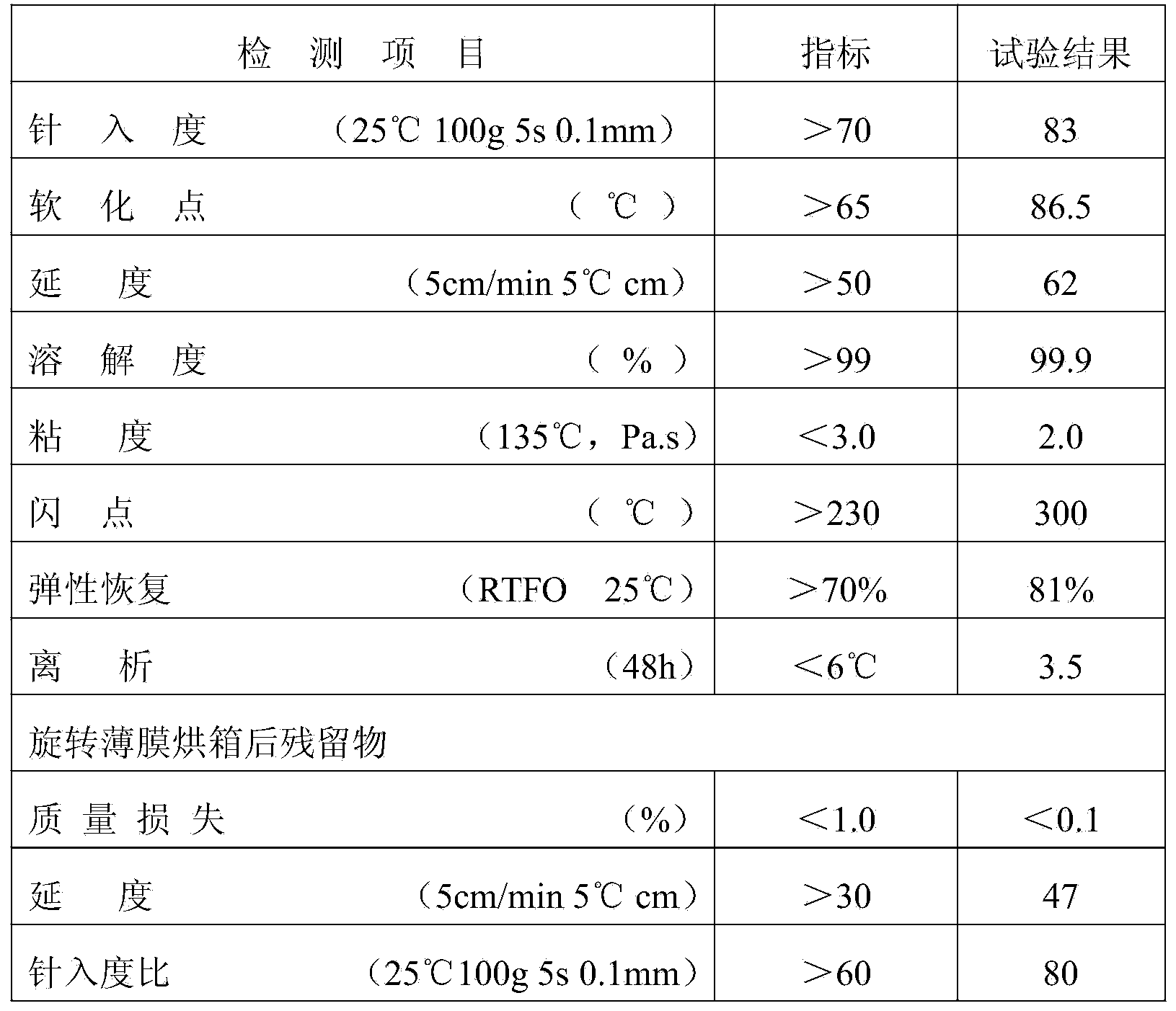

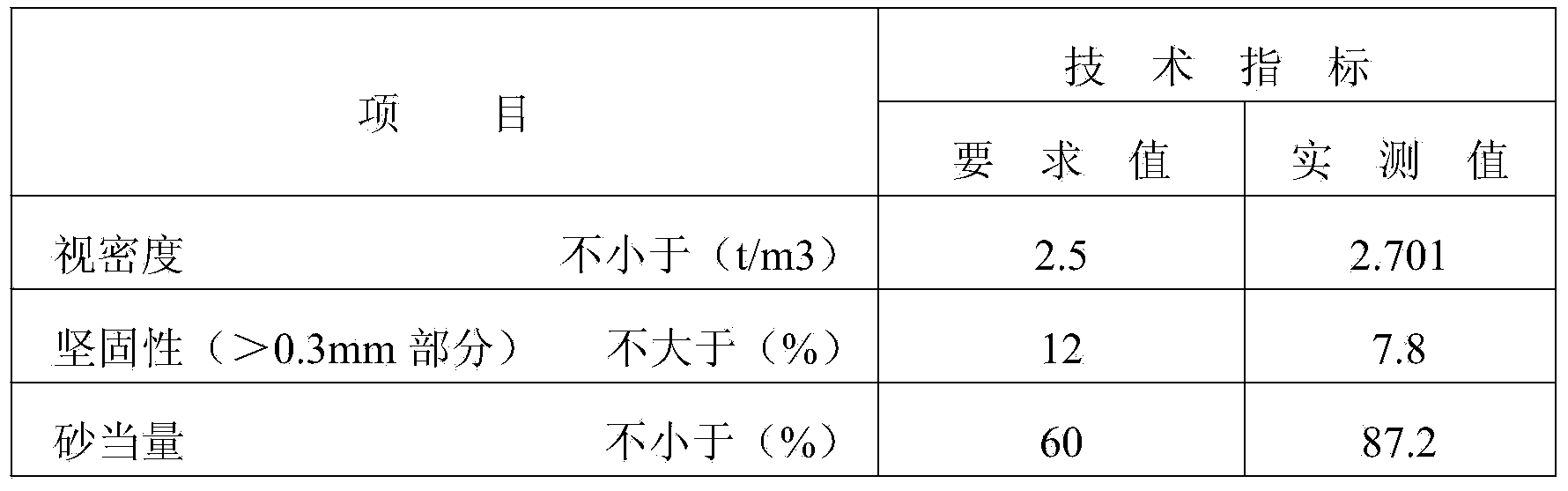

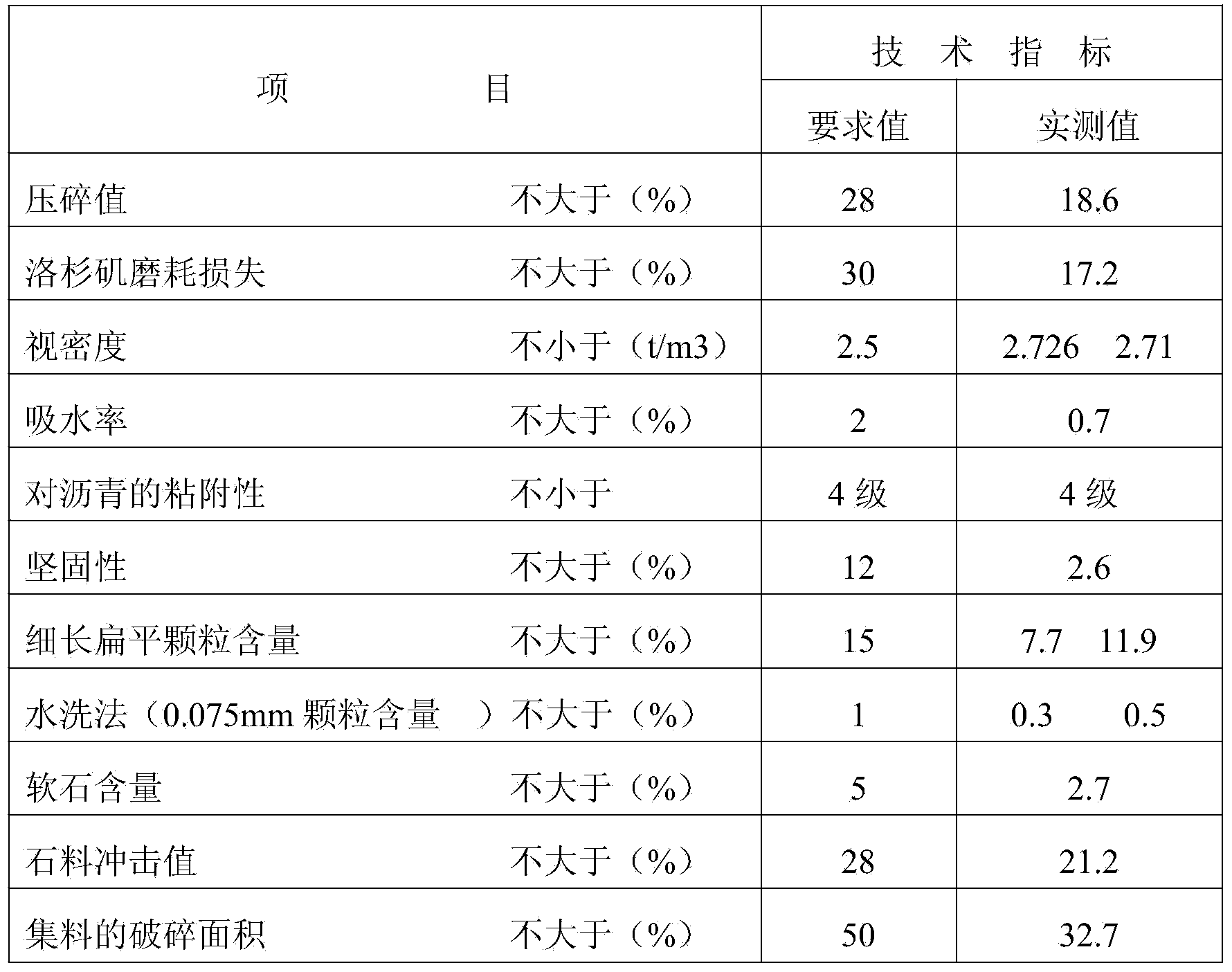

[0037] The performance and detection indicators of each component are introduced as follows: ...

Embodiment 2

[0068] An overlay construction process for a highly elastic-viscosity stress-absorbing layer, comprising the following steps in sequence:

[0069] Step 1) Design of the mix proportion of the highly elastic-viscosity stress-absorbing layer;

[0070] Step 2) Determine the plane position and prepare before construction;

[0071] Step 3) mixing, transporting, paving and rolling of the polymer modified asphalt concrete mixture.

Embodiment 3

[0073] Present embodiment is on the basis of embodiment 2, and step 1) comprises:

[0074] (1) Target mix ratio design stage: screen mineral materials, determine mineral material gradation composition and polymer modified asphalt dosage, test mixture performance through Vim stability and bending fatigue test, establish stress absorbing layer and cement concrete pavement The relationship curve between intensity and ambient temperature.

[0075] (2) Production mix ratio design stage: determine the mix ratio of the hot silo in the mixing building, and conduct the volume performance test of the mixture;

[0076] (3) Production mix ratio verification stage: through asphalt leakage test and residual Marshall stability test, verify whether the mixture meets the production control basis and quality inspection standards.

[0077] The production mixing ratio of each hot material bin in the mixing building is that the 1# bin accounts for 66%, the 2# bin accounts for 29%, and the mineral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com