Ammonia gas sensor based on polyaniline/graphene nanoribbons/silicon dioxide/silicon

A graphene nanoribbon and ammonia sensor technology, applied in the field of ammonia sensors, can solve the problems of ammonia detection, short life, poor stability, etc., and achieve the effects of short recovery time, low energy consumption and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

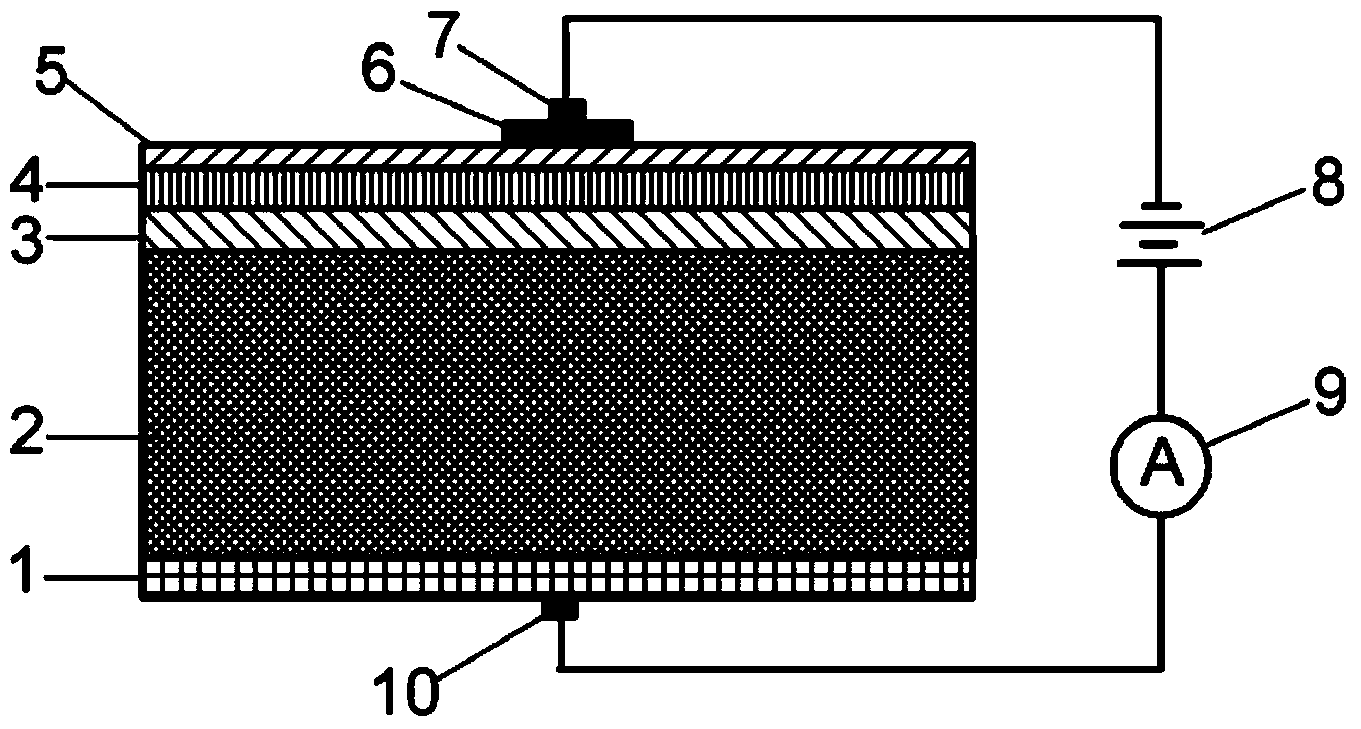

[0022] Example 1, 2.5 mg of graphene oxide nanobelts prepared by oxidizing and longitudinally exfoliating multi-walled carbon nanotubes were added to 30 milliliters of deionized water, and ultrasonic (power was 40 watts) was dispersed for 5 minutes to obtain a graphene oxide nanobelt solution; The graphene nanoribbon solution is placed in a filter membrane (cellulose acetate filter membrane) with a pore size of 0.44 micron in a suction filtration device, and is vacuum filtered so that the upper surface of the filter paper is uniformly attached to a layer of graphene oxide nanoribbon film, the filter paper is taken out, and After drying at 80°C for 1 hour, the filter paper was soaked in deionized water to keep it moist. as attached figure 1 , select the silicon wafer (2) that retains the natural oxide layer (3) with a thickness of 0.5 mm as the substrate, and clean the silicon wafer for 5 minutes in ultrasonic waves (power of 100 watts) with ethanol, acetone and deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com