Structure of MIS capacitor with capacitance being variable and manufacturing method thereof

A technology with variable capacitance value, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of power amplifier output power, gain and efficiency reduction, inability to match the working voltage range of power amplifiers, and inability to match all of them. Achieve the effect of increasing output power, reducing difficulty, and reducing nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

[0028] The MIS capacitor applied in the RFLDMOS technology of the present invention, its specific manufacturing process is as follows:

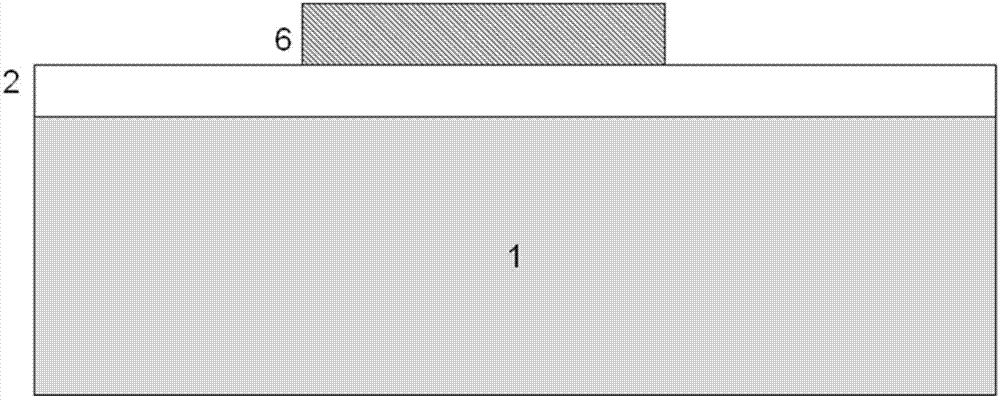

[0029] Step 1, grow N-type lightly doped silicon epitaxy 2 on N-type heavily doped silicon substrate 1, such as image 3 shown.

[0030] Step 2, grow a layer of silicon oxide 3 of about 100 Angstroms on the N-type lightly doped epitaxy 2 as a sacrificial oxide layer, such as Figure 4 shown.

[0031] Step 3, define an N-type ion implantation region through the photoresist 4, and perform vertical N-type ion implantation, such as Figure 5 shown. In this embodiment, phosphorous ions are implanted, the implantation energy is 30-100keV, and the implantation dose is 1e12-1e14cm -2 .

[0032] Step 4, perform the implantation of ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com