Processing method for improving crispness and elasticity of meatball products

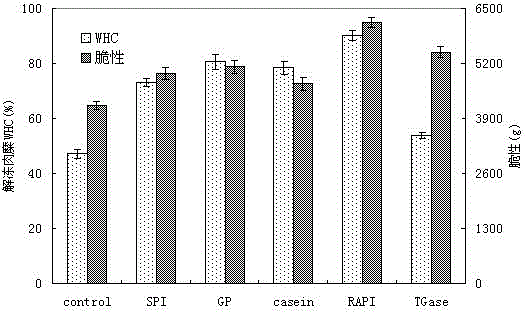

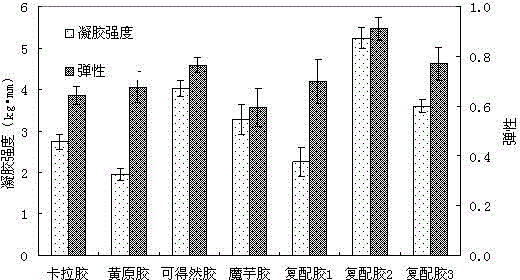

A processing method and technology of tribute balls, which is applied in the processing of tribute ball products and the processing field of improving the brittleness and elasticity of tribute ball products, can solve the problems of strict temperature and time control, difficulty for operators to master, cumbersome process operation, etc., and achieve Process parameters are easy to grasp, improve gel strength, increase emulsification and water holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

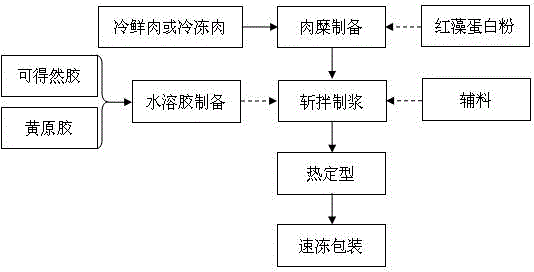

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: red algae protein powder preparation:

[0040]Fresh asparagus, asparagus or seaweed, add appropriate amount of phosphate buffer solution, use a tissue grinder to break the algae cells, and centrifugally filter to get the supernatant, the saturation is 60% ammonium sulfate salting out, the molecular weight cut-off is 30kDa ultrafiltration and desalination, concentrated by rotary evaporator, and then freeze-dried, the crude protein content is more than 90%.

Embodiment 2

[0042] (1) Preparation of hydrosol:

[0043] Pour 6,000 grams of water into the chopping machine, start the chopping machine, slowly add 500 grams of curdlan gum and xanthan gum compound gum (combining ratio 1:1), and chop and mix at medium and low speed for 3 minutes to form water Dispersion, then slowly add 10 grams of edible tricalcium phosphate, chop and mix at high speed for 5 minutes to form a hydrosol, divide it into plastic belts, spread it flat (thickness 4-5 cm), and place it in a 4°C freezer for later use;

[0044] (2) Preparation of minced meat:

[0045] 1000 grams of chilled fresh pork hind legs are minced with a 5mm orifice plate, then placed in a chopping machine for 1 minute, add 5 grams of red algae protein powder, chop and mix for 3 minutes at a high speed, and then freeze at -20°C Storage in the library, spare.

[0046] (3) chopping and pulping:

[0047] Take 700 grams of minced meat prepared in step (2), put it in the chopping machine after thawing, turn...

Embodiment 3

[0053] (1) Preparation of hydrosol:

[0054] After pouring 6500 grams of water into the chopping machine, start the chopping machine, slowly add 500 grams of curdlan gum and xanthan gum compound gum (combining ratio 1:1), and chop and mix at medium and low speed for 3 minutes to form water Add 31.5 grams of edible tricalcium phosphate to the dispersion, chop and mix at high speed for 5 minutes to form a hydrosol, pack it into plastic belts, spread it flat (thickness 4-5 cm), and place it in a 4°C freezer for later use;

[0055] (2) Preparation of minced meat:

[0056] 1,000 grams of frozen pork hind legs are minced with a 5mm orifice plate, then placed in a chopping machine for 1 minute, add 8 grams of red algae protein powder, chopped and mixed for 3 minutes at a high speed, and then placed in a -20°C freezer Store in China and reserve.

[0057] (3) chopping and pulping:

[0058] Take 750 grams of minced meat prepared in step (2), put 500 grams of sol into the chopping mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com