Efficient non-phosphorus non-nitrogen environment-friendly dedicated scale inhibitor for reverse osmosis membrane

A reverse osmosis membrane and antiscalant technology, which is applied in the field of high-efficiency phosphorus-free, non-nitrogen, and environmentally friendly antiscalant for reverse osmosis membranes, can solve the problems of restricting economic benefits and high proportions of enterprises, and achieve technological progress, easy degradation, and good performance. The effect of scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

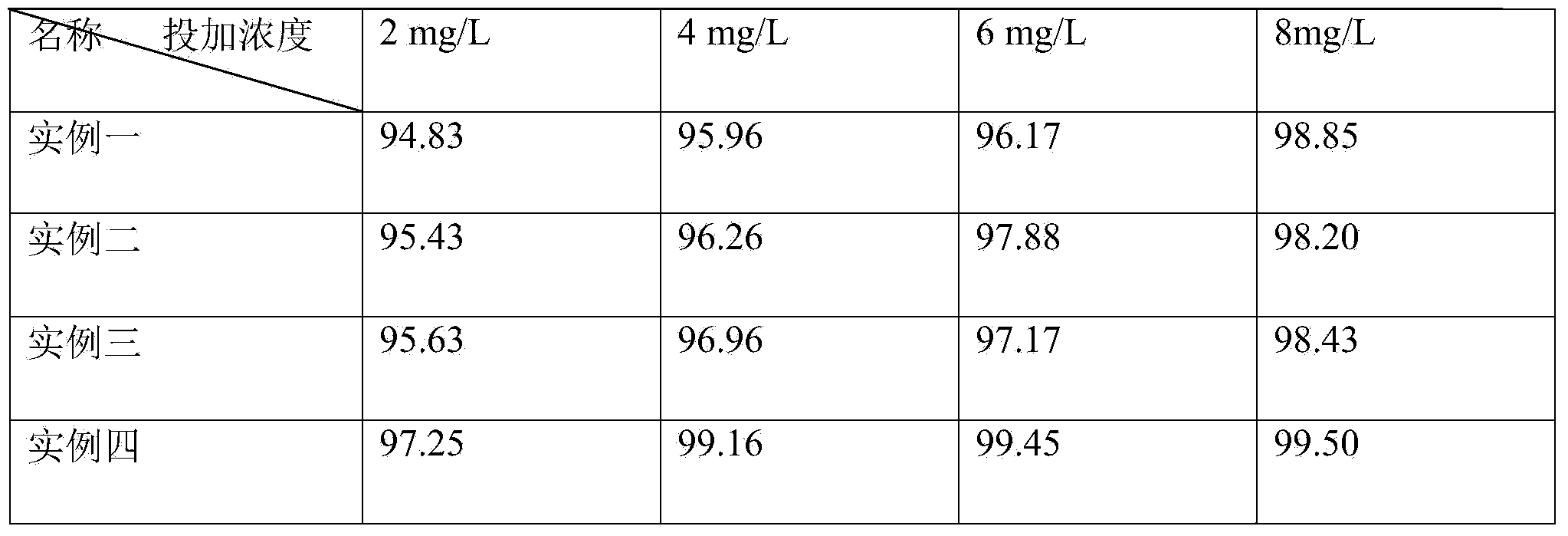

Examples

Embodiment 1

[0007] Example 1. A high-efficiency non-phosphorus, non-nitrogen, and environment-friendly antiscalant special for reverse osmosis membranes. The antiscalant is prepared from the following raw materials in parts by weight: polyepoxysuccinic acid: 40 parts, KF-308 dispersion Dispersant: 15 parts, hydrolyzed polymaleic anhydride: 5 parts, hydrochloric acid: 2 parts, desalted water: 30 parts, wherein, the KF-308 dispersant is a product produced by Urumqi Kefafa Fine Chemical Co., Ltd., mainly The components are: hydroxypropyl acrylate, 2-acrylamide-2-methylpropanesulfonic acid, ammonium persulfate, and isopropanol; the specifications of the hydrochloric acid are: analytically pure.

[0008] Preparation method: Put polyepoxysuccinic acid, KF-308 dispersant, hydrolyzed polymaleic anhydride, hydrochloric acid, and desalinated water into the reaction kettle in sequence, stir for 0.5-1.2h at 55-70rpm, filter with 200 mesh, Instant antiscalant products.

Embodiment 2

[0009] Example 2. A high-efficiency non-phosphorus, non-nitrogen, and environment-friendly antiscalant dedicated to reverse osmosis membranes. The antiscalant is prepared from the following raw materials in parts by weight: polyepoxysuccinic acid: 50 parts, KF-308 dispersed Dispersant: 15 parts, hydrolyzed polymaleic anhydride: 5 parts, hydrochloric acid: 2 parts, desalted water: 30 parts, wherein, the KF-308 dispersant is a product produced by Urumqi Kefafa Fine Chemical Co., Ltd., mainly The components are: hydroxypropyl acrylate, 2-acrylamide-2-methylpropanesulfonic acid, ammonium persulfate, isopropanol. The specification of described hydrochloric acid is: analytical pure.

[0010] The preparation method is the same as in Example 1.

Embodiment 3

[0011] Example 3. A high-efficiency non-phosphorus, non-nitrogen, and environment-friendly antiscalant special for reverse osmosis membranes. The antiscalant is prepared from the following raw materials in parts by weight: polyepoxysuccinic acid: 60 parts, KF-308 dispersion Dispersant: 10 parts, hydrolyzed polymaleic anhydride: 5 parts, hydrochloric acid: 2 parts, desalted water: 30 parts, wherein, the KF-308 dispersant is a product produced by Urumqi Kefafa Fine Chemical Co., Ltd., mainly The components are: hydroxypropyl acrylate, 2-acrylamide-2-methylpropanesulfonic acid, ammonium persulfate, and isopropanol; the specifications of the hydrochloric acid are: analytically pure.

[0012] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com