Ultralow-emission stabilizer for boiler water system and preparation method of same

A stabilizer and ultra-low technology, which is applied in the field of ultra-low emission stabilizer and its preparation for boiler water system, can solve the problems of serious corrosion of water-cooled wall tubes, reduce boiler blowdown rate, increase concentration ratio, save water resources and The effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

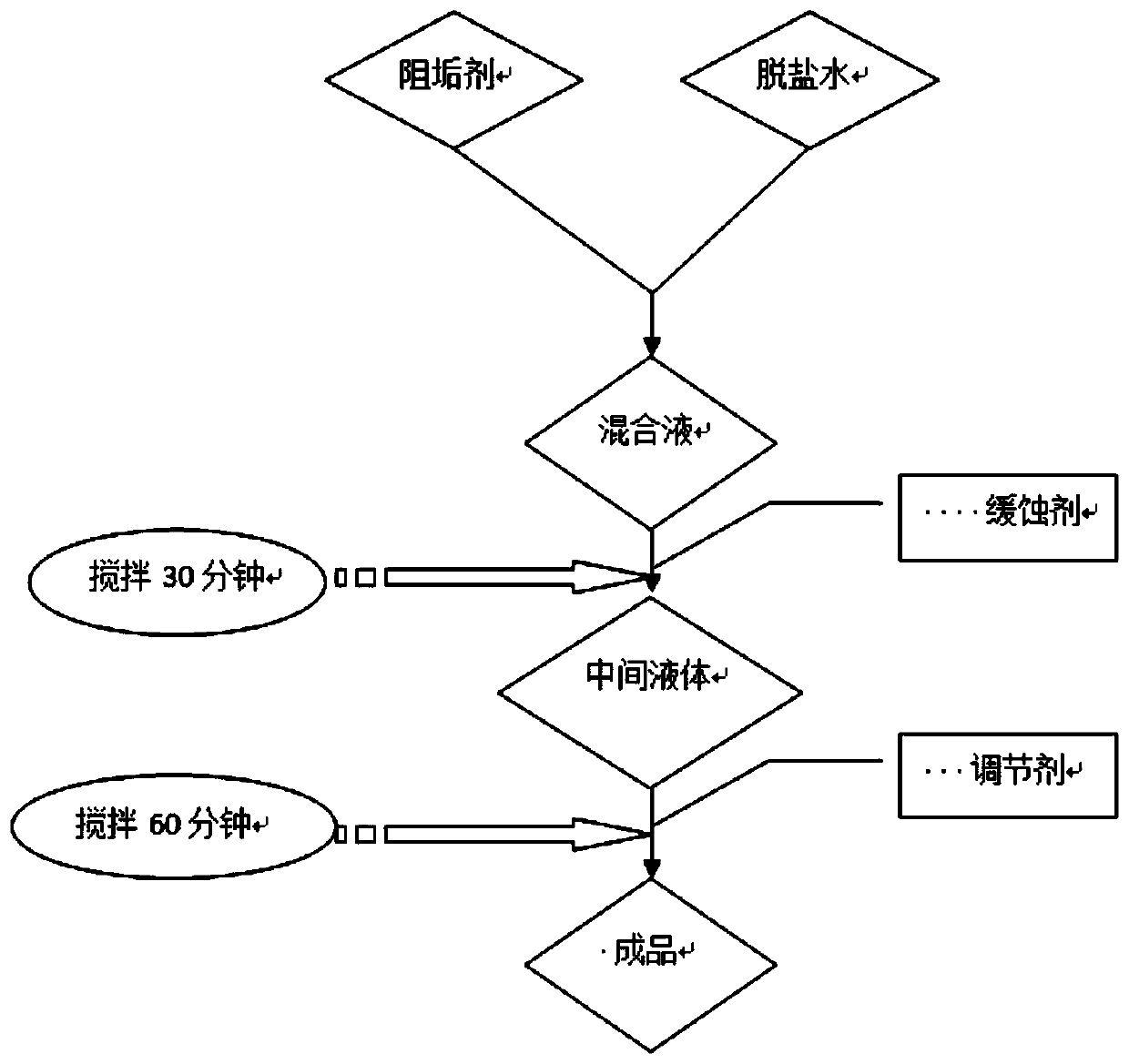

Method used

Image

Examples

Embodiment 1

[0047] The scale inhibitor is nitrilotriacetic acid trisodium salt, the corrosion inhibitor is sodium molybdate and azodicarbonamide, the regulator is sodium hydroxide, calculated according to mass percentage, nitrilotriacetic acid trisodium salt 23-35%, sodium molybdate 8-10%, azodicarbonamide 2-4%, sodium hydroxide 7-8%, and the balance desalinated water.

Embodiment 2

[0049] The antiscalant is ethylenediaminetetraacetic acid disodium and nitrilotriacetic acid trisodium salt, the corrosion inhibitor is sodium molybdate and azodicarbonamide, and the regulator is sodium hydroxide. Calculated according to mass percentage, ethylenediaminetetraacetic acid di Sodium is 20-38%, nitrilotriacetic acid trisodium salt 13-15%, sodium molybdate is 8-10%, azodicarbonamide is 2-4%, sodium hydroxide is 7-8%, and the balance is desalination water.

Embodiment 3

[0051] The scale inhibitor is disodium ethylenediaminetetraacetic acid and hydroxyphosphorylacetic acid, the corrosion inhibitor is sodium molybdate, and the regulator is sodium hydroxide. Calculated by mass percentage, disodium edetate is 20-38%. Nitrilotriacetic acid trisodium salt 10-13%, sodium molybdate 9-12%, sodium hydroxide 9-14%, and the balance is desalinated water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com