Large-area high-density nuclear track nano-pore membrane, as well as equipment and method for preparing large-area high-density nuclear track nano-pore membrane

A nuclear track and nanopore technology, which is applied in the field of preparing large-area high-density nuclear track nanoporous membranes, can solve the problems of difficult uniform etching of films, uncontrollable etching rate, high track density, etc., and achieve excellent anti-reflection performance , Accelerate the etching rate, the effect of high hole density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

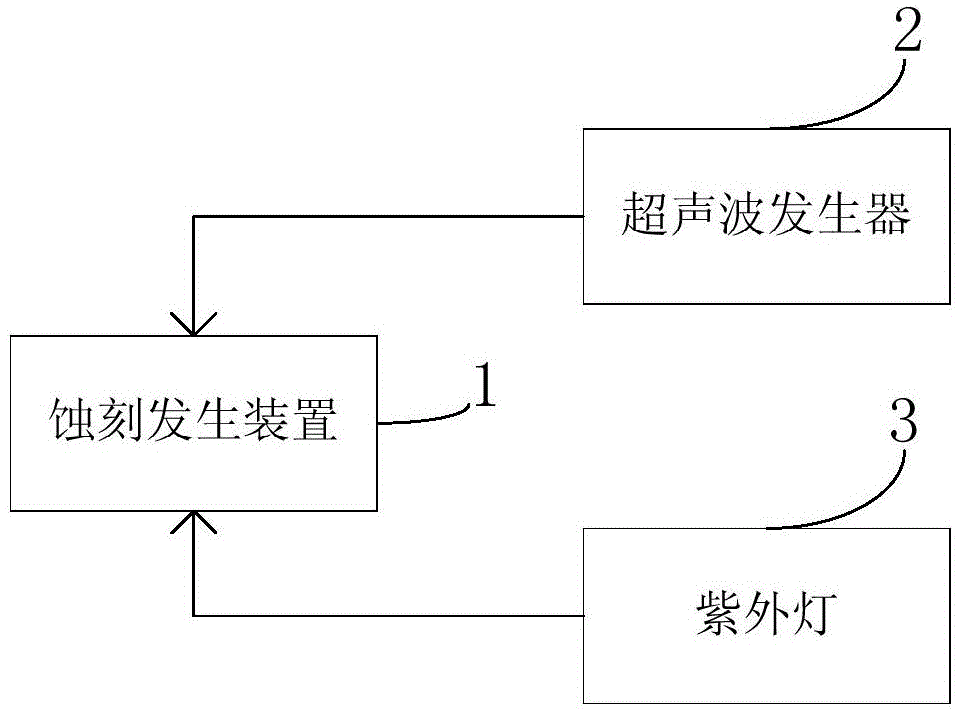

[0048] see figure 1 As shown, it is a functional block diagram of Embodiment 1 of the equipment for preparing large-area high-density nuclear track nanoporous membranes in the present invention, and the equipment includes:

[0049] An etching generating device 1, which is used to contain an etching solution and fix the ion-irradiated sneaking track film in the etching solution for etching, so that the diving track film is uniformly etched;

[0050] An ultrasonic generator 2 is used to strip off the etching products remaining in the track holes in time to accelerate the etching rate;

[0051] An ultraviolet lamp 3 is used for radiation sensitization of the submerged track film to accelerate the etching rate.

Embodiment 2

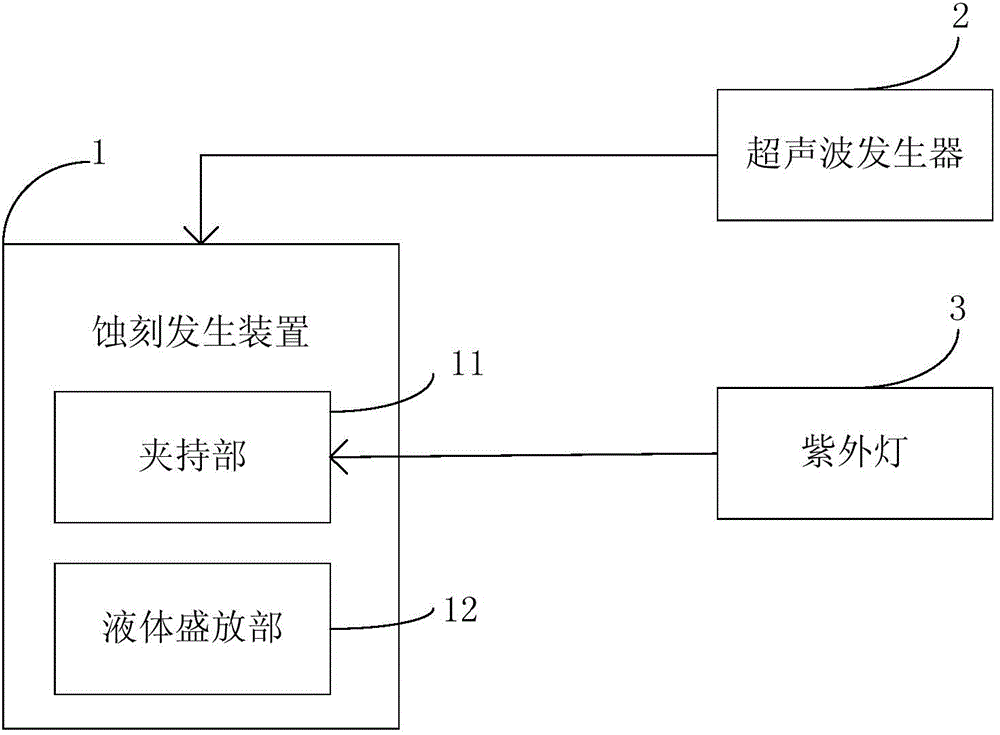

[0053] see figure 2 As shown, it is a functional block diagram of Embodiment 2 of the equipment for preparing a large-area high-density nuclear track nanoporous membrane in the present invention. As described in Embodiment 1, the difference between this embodiment and it is that the equipment also includes:

[0054] An etching generating device 1 is used to contain an etching solution and fix the submerged track film irradiated with ions in the etching solution for etching;

[0055]An ultrasonic generator 2, which provides ultrasonic waves to the etching generating device 1, in order to strip off the etching products remaining in the track holes in time, thereby accelerating the etching rate;

[0056] A UV lamp 3 is used to sensitize the submerged track film to accelerate the etching rate.

[0057] Wherein, the etching generating device 1 includes:

[0058] A clamping part 11 is used to clamp and fix the submerged track film. When the ultraviolet lamp 3 is used for sensitiz...

Embodiment 3

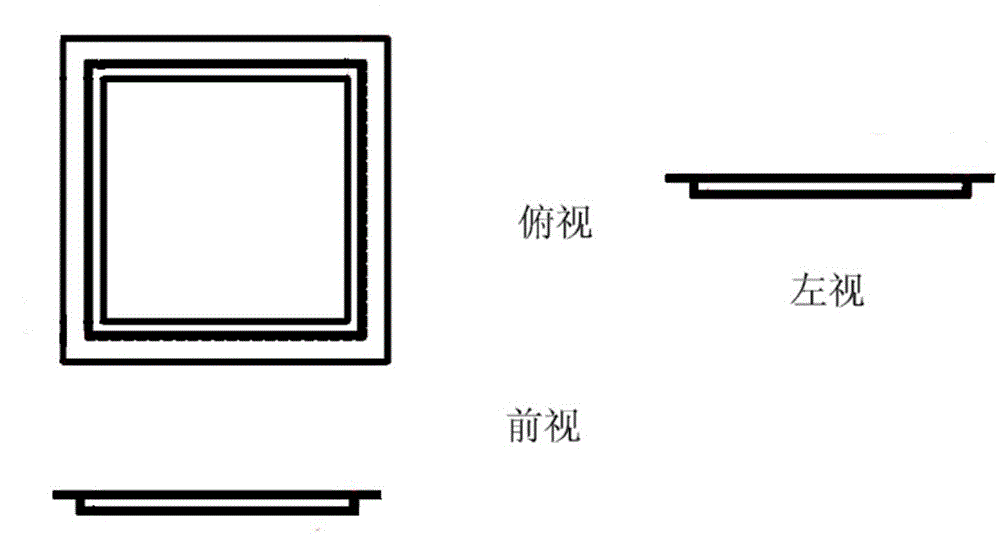

[0061] As described in Embodiment 2, the difference of this embodiment is that the clamping part 11 described in the etching generating device 1 is a carrier film clip, and the carrier film clip is designed as two sub-clamps and a mother clip superimposed on the together, see image 3 As shown, it is the top view, left view and front view of the film-carrying clip clip in the present invention, Figure 4 As shown, it is the top view, left view and front view of the mother clip of the film carrier clip in the present invention. Both the sub clip and the mother clip are frame-type structures, hollow, and the cross section of the frame is an inverted L shape. The bottom of the mother clip frame is provided with a first extension plate inwards around the edge to support the submerged track film. The above-mentioned sub-clip is matched with the mother clip, and the same position as the frame of the sub-clip and the mother clip is provided with a drill hole, and the sub-clip and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com