Ultrasonic-assisted prepared ultralow-concentration methane combustion catalyst and preparation method thereof

A methane combustion, ultra-low concentration technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. problems such as less load, to achieve the effects of short preparation cycle, simple preparation process, and improved catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0023] A preparation method for ultrasonically assisted preparation of an ultra-low concentration methane combustion catalyst, the method comprising the steps of:

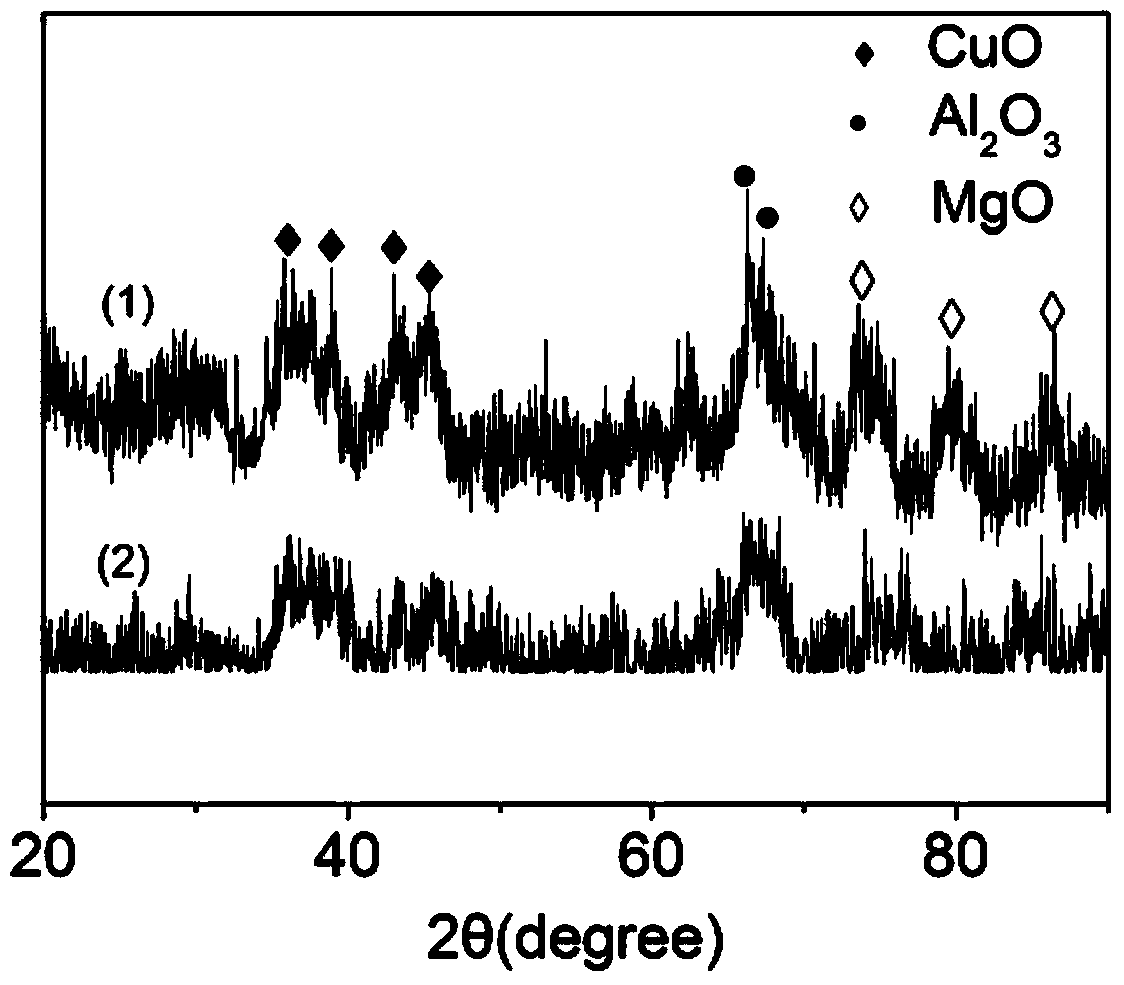

[0024] (1) Add appropriate amount of Mg(NO 3 ) 2 Dissolved in deionized water, configured as 0.3mol / L Mg(NO 3 ) 2 solution. Then the granular γ-Al with a diameter of 120-150 mesh 2 o 3 impregnated into Mg(NO 3 ) 2 In the solution, stirred and impregnated with a magnetic stirrer for 5h, evaporated to dryness in a drying oven at 120°C, and roasted in a muffle furnace at 700°C for 8h to obtain a carrier γ-Al loaded with additive MgO 2 o 3 -MgO.

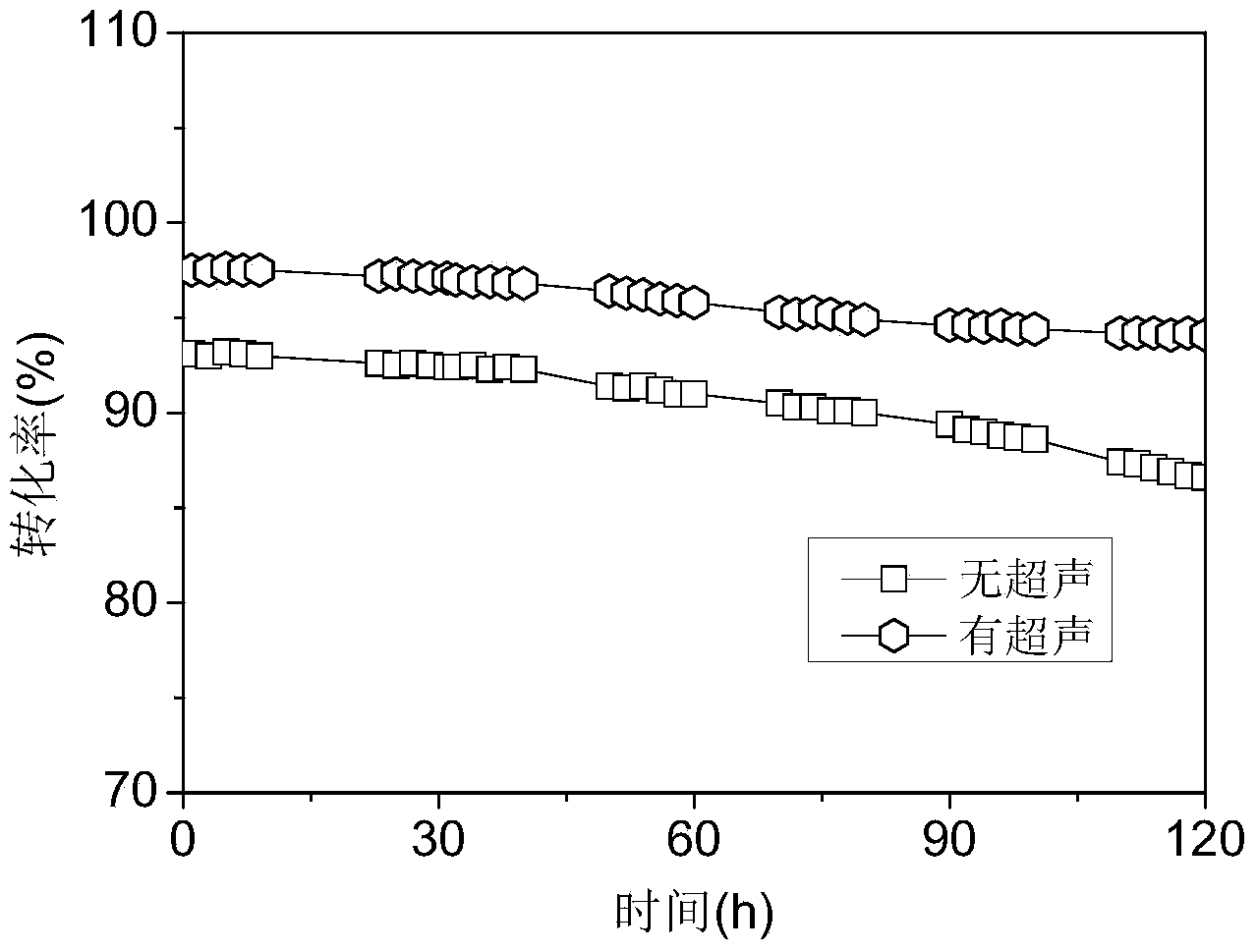

[0025] (2) Adding an appropriate amount of Cu(NO 3 ) 2 Dissolved in deionized water, prepared to a concentration of 0.3mol / L Cu(NO 3 ) 2 solution, the prepared carrier γ-Al 2 o 3 -MgO impregnated into Cu(NO 3 ) 2 In the solution, use a constant temperature water bath to keep the solution temperature at 20°C, and use an ultrasonic sonochemical treatment device...

Embodiment example 2

[0030] A preparation method for ultrasonically assisted preparation of an ultra-low concentration methane combustion catalyst, the method comprising the steps of:

[0031] (1) Add appropriate amount of Mg(NO 3 ) 2 Dissolved in deionized water, configured as 0.3mol / L Mg(NO 3 ) 2 solution. Then the granular γ-Al with a diameter of 120-150 mesh 2 o 3 impregnated into Mg(NO 3 ) 2 In the solution, stirred and impregnated with a magnetic stirrer for 5h, evaporated to dryness in a drying oven at 120°C, and roasted in a muffle furnace at 700°C for 8h to obtain a carrier γ-Al loaded with additive MgO 2 o 3 -MgO.

[0032] (2) Adding an appropriate amount of Cu(NO 3 ) 2 Dissolved in deionized water, prepared to a concentration of 0.3mol / L Cu(NO 3 ) 2 solution, the prepared carrier γ-Al 2 o 3 -MgO impregnated into Cu(NO 3 ) 2 In the solution, use a constant temperature water bath to keep the solution temperature at 30°C, and use an ultrasonic sonochemical treatment device...

Embodiment example 3

[0035] A preparation method for ultrasonically assisted preparation of an ultra-low concentration methane combustion catalyst, the method comprising the steps of:

[0036] (1) Add appropriate amount of Mg(NO 3 ) 2 Dissolved in deionized water, configured as 0.3mol / L Mg(NO 3 ) 2 solution. Then the particle size is 120 mesh γ-Al 2 o 3 impregnated into Mg(NO 3 ) 2 In the solution, stirred and impregnated with a magnetic stirrer for 5h, evaporated to dryness in a drying oven at 120°C, and roasted in a muffle furnace at 700°C for 8h to obtain a carrier γ-Al loaded with additive MgO 2 o 3 -MgO.

[0037] (2) Adding an appropriate amount of Cu(NO 3 ) 2 Dissolved in deionized water, prepared to a concentration of 0.4mol / L Cu(NO 3 ) 2 solution, the prepared carrier γ-Al 2 o 3 -MgO impregnated into Cu(NO 3 ) 2 In the solution, use a constant temperature water bath to keep the solution temperature at about 25°C, and use an ultrasonic sonochemical treatment device to assis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com