Manufacturing technology of threading box

A manufacturing process and threading box technology, applied in the direction of coating, etc., can solve the problems of complicated labor, the quality and quantity of plastic parts cannot meet the needs of production development, etc., achieve excellent high-frequency insulation performance, save human resources and time, and make Sophisticated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

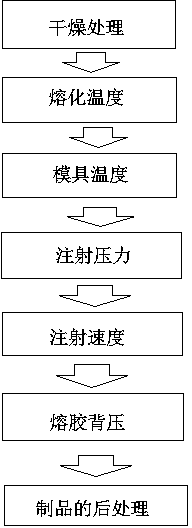

[0026] b. Melting temperature: The melting point of PP is 160°C, and the decomposition temperature is 350°C. The temperature setting during injection processing should not exceed 275°C, and the temperature of the melting section should be 240°C;

[0027] c. Mold temperature: The mold temperature is 50°C. For those with high size requirements, use a high mold temperature. The core temperature is more than 5°C lower than the cavity temperature;

[0028] d. Injection pressure: use a higher injection pressure of 15000bar and a holding pressure of about 80% of the injection pressure, turn to holding pressure at 95% of the full stroke, and use a longer holding time;

[0029] e. Injection speed: In order to reduce internal stress and deformation, high-speed injection should be selected. Runner and gate: the diameter of the runner is 4-7mm, the length of the needle gate is 1mm, the diameter can be as small as 0.7mm, and the thickness of the rib is 50 %, for products made of homopolyme...

Embodiment 2

[0038] b. Melting temperature: The melting point of PP is 170°C, and the decomposition temperature is 350°C. The temperature setting during injection processing cannot exceed 275°C, and the temperature of the melting section is preferably 240°C;

[0039] c. Mold temperature: The mold temperature is 70°C. For those with high size requirements, use a high mold temperature. The core temperature is more than 5°C lower than the cavity temperature;

[0040] d. Injection pressure: use a higher injection pressure of 1650bar and a holding pressure of about 80% of the injection pressure, turn to holding pressure at 95% of the full stroke, and use a longer holding time;

[0041] e. Injection speed: In order to reduce internal stress and deformation, high-speed injection should be selected. Runner and gate: the diameter of the runner is 4-7mm, the length of the needle gate is 1.2mm, the diameter can be as small as 0.7mm, and the thickness of the rib is 55%, for products made of homopolyme...

Embodiment 3

[0050] b. Melting temperature: The melting point of PP is 175°C, and the decomposition temperature is 350°C. The temperature setting during injection processing cannot exceed 275°C, and the temperature of the melting section is preferably 240°C;

[0051] c. Mold temperature: The mold temperature is 90°C. For those with high size requirements, use high mold temperature. The core temperature is more than 5°C lower than the cavity temperature;

[0052] d. Injection pressure: use a higher injection pressure of 1800bar and a holding pressure of about 80% of the injection pressure, turn to holding pressure at 95% of the full stroke, and use a longer holding time;

[0053] e. Injection speed: In order to reduce internal stress and deformation, high-speed injection should be selected. Runner and gate: the diameter of the runner is 7mm, the length of the needle gate is 1.5mm, the diameter can be as small as 0.7mm, and the thickness of the rib is 60% , products made of homopolymer PP, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com