Method for extracting bromine from brine

A brine and bromine technology, applied in the directions of bromine, bromine/hydrogen bromide, etc., can solve the problems of bromine production capacity decline, brine grade decline, etc., and achieve the effect of improving extraction rate and high blowing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

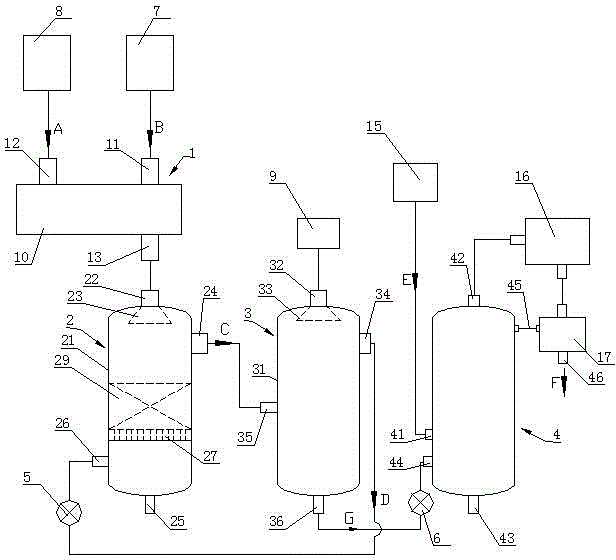

[0023] Realize that the used bromine extracting device of process method of the present invention is as figure 1 As shown, it includes a gas-liquid mixer 1, a blowing tower 2, an absorption tower 3 and a distillation tower 4 arranged in sequence according to the process route. The gas and liquid mixer 1 is an existing product including a mixer main body 10, the mixer main body 10 is provided with a gas inlet 11, a liquid inlet 12 and a material outlet 13; Brine supply device 8. The blowing tower 2 comprises a tower body 21, the outer top of the tower body 21 is provided with a liquid inlet 22, the top of the inner chamber of the tower body 21 is provided with a feed liquid spraying device 23 communicated with the liquid inlet 22, and the upper part of the tower body 21 is provided with a drain Air port 24, liquid outlet 25 is provided at the bottom of tower body 21, and air inlet 26 is provided at the lower part of tower body 21 side, and partition plate 27 is arranged in tow...

Embodiment 2

[0026] The bromine extraction method comprises the following steps:

[0027] (1) Acidify the brine to a pH value of 3, then send it into the gas-liquid mixer through the brine supply device 8, and simultaneously pass the chlorine gas through the chlorine gas delivery device 7 according to the amount of 1.02 moles of chlorine gas per mole of bromide ion in the brine. Into the gas and liquid mixer 1 to react with acidified brine at normal temperature to oxidize bromide ions into free bromine, thereby producing oxidized brine;

[0028] (2) After the oxidized brine flows out of the gas-liquid mixer 1, it flows into the feed liquid spray device 23 from the liquid inlet 22 of the blowing tower 2 and sprays downward, forming a liquid film on the surface of the filler 29, and at the same time passing through the blower 5 The air is blown into the blowing tower 2 from the air inlet 26 of the blowing tower 2, the speed of the fan is controlled and the spray volume of the material-liquid...

Embodiment 3

[0032] The bromine extraction method comprises the following steps:

[0033] (1) Acidify the brine to a pH value of 3.5, then send it into the gas-liquid mixer through the brine supply device 8, and simultaneously pass the chlorine gas through the chlorine gas delivery device 7 according to the amount of 1.25 moles of chlorine gas per mole of bromide ion in the brine. Into the gas and liquid mixer 1 to react with acidified brine at normal temperature to oxidize bromide ions into free bromine, thereby producing oxidized brine;

[0034](2) After the oxidized brine flows out of the gas-liquid mixer 1, it flows into the feed liquid spray device 23 from the liquid inlet 22 of the blowing tower 2 and sprays downward, forming a liquid film on the surface of the filler 29, and at the same time passing through the blower 5 Air is blown into the blowing tower 2 from the air inlet 26 of the blowing tower 2, the speed of the fan is controlled and the spray volume of the material-liquid sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com