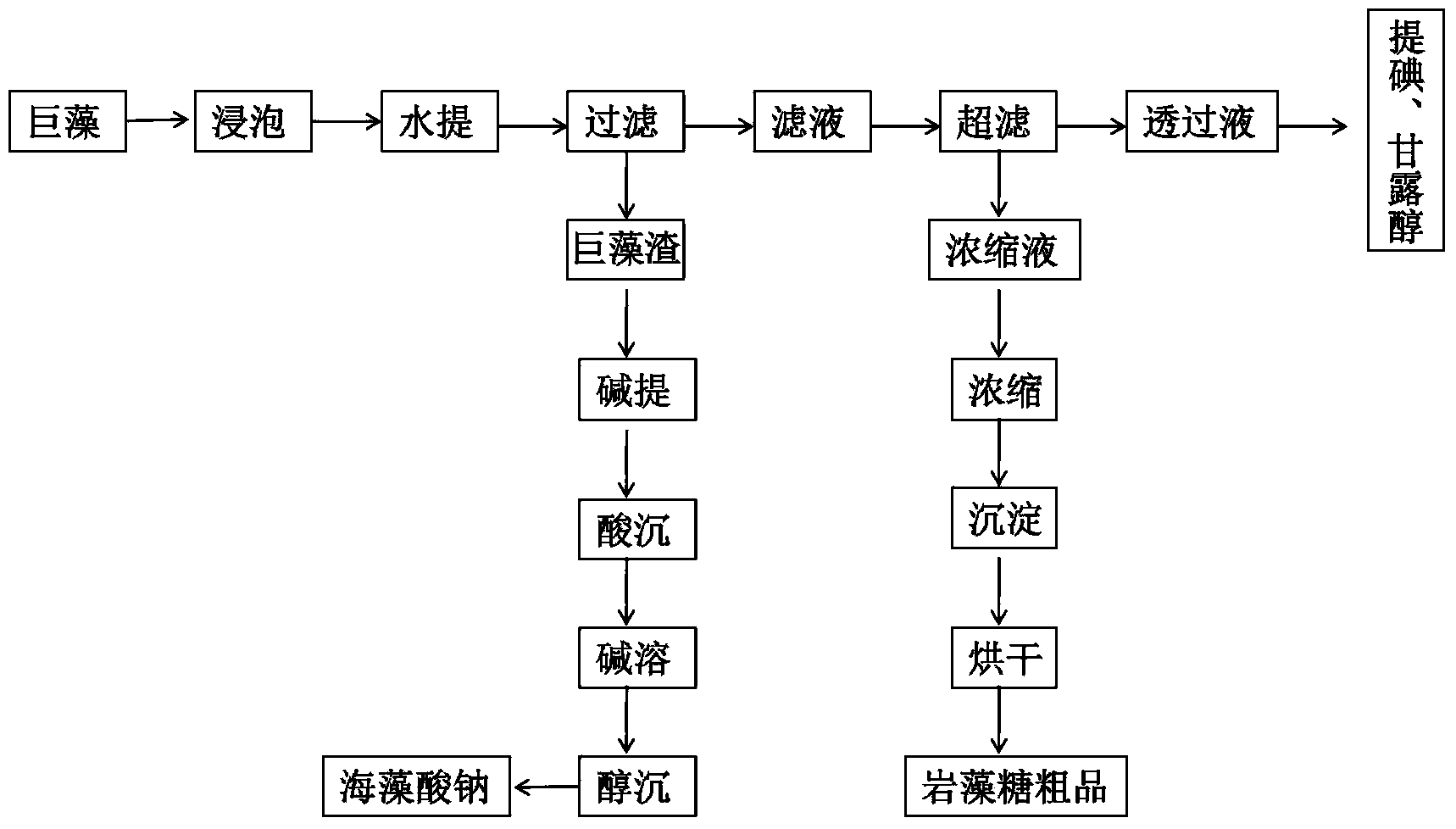

Kelp deep processing method

A technology for deep processing and macroalgae, applied in chemical instruments and methods, preparation of monosaccharides and sugar derivatives, etc., can solve the problems of low yield and high cost, and achieve the effects of improved yield, high output efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Take 20g of dried macroalgae, soak in 200ml of distilled water for 8 hours, extract in a water bath at 70°C for 8 hours, obtain the filtrate and macroalgae residue after coarse filtration, and ultrafiltrate the filtrate through a membrane with a molecular weight cut-off of 3600Da to obtain the permeate and concentrate Wherein the permeated liquid can be used as the raw material for extracting iodine and mannitol; the concentrated liquid is conventionally concentrated by vacuum distillation and then added with 3 times the volume of 95% ethanol aqueous solution, placed under temperature control at 4°C for 12 hours, and then centrifuged, After precipitation and drying, fucose was obtained, and the extraction rate of fucose was 0.6%; adding weight percent concentration of 0.5% sodium carbonate (NaCO 3 ) aqueous solution 150ml, extracted for 1 hour, after dilution and filtration, the pH value was adjusted to 2, and after filtration, adding 400ml of sodium hydroxide (NaOH) aqu...

Embodiment 2

[0016] Take 20g of dried macroalgae, add 200ml of distilled water to soak for 0.5 hours, extract in a water bath at 90°C for 8 hours, obtain filtrate and macroalgae residue after coarse filtration, and ultrafiltrate the filtrate through a membrane with a molecular weight cut-off of 5000Da to obtain permeate and concentrate Wherein the permeated liquid can be used as the raw material for extracting iodine and mannitol; the concentrated liquid is conventionally concentrated by vacuum distillation and then added with 3 times the volume of 95% ethanol aqueous solution, placed under temperature control at 4°C for 12 hours, and then centrifuged, After precipitation and drying, fucose was obtained, and the extraction rate of fucose was 0.8%; adding 3% sodium carbonate (NaCO 3 ) aqueous solution 150ml, extracted for 20 hours, after dilution and filtration, the pH value was adjusted to 2, and after filtration, adding 300ml of sodium hydroxide (NaOH) aqueous solution with a weight percen...

Embodiment 3

[0018] Take 20g of dried macroalgae, add 200ml of distilled water to soak for 48 hours, extract in a water bath at 80°C for 24 hours, obtain the filtrate and macroalgae residue after coarse filtration, and ultrafiltrate the filtrate through a membrane with a molecular weight cut-off of 3600Da to obtain the permeate and concentrate Wherein the permeated liquid can be used as the raw material for extracting iodine and mannitol; the concentrated liquid is conventionally concentrated by vacuum distillation and then added with 3 times the volume of 95% ethanol aqueous solution, placed under temperature control at 4°C for 12 hours, and then centrifuged, After precipitation and drying, fucose was obtained, and the extraction rate of fucose was 1.0%; sodium carbonate (NaCO 3 ) aqueous solution 150ml, extracted for 48 hours, after dilution and filtration, the pH value was adjusted to 2, and after filtration, adding 500ml of sodium hydroxide (NaOH) aqueous solution with a weight percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com