Method of preparing collagen

A collagen and protease technology, applied in the biological field, can solve problems such as complex process, low extraction rate, heavy metal residue, etc., and achieve the effect of large contact area, improved extraction rate, and rapid enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

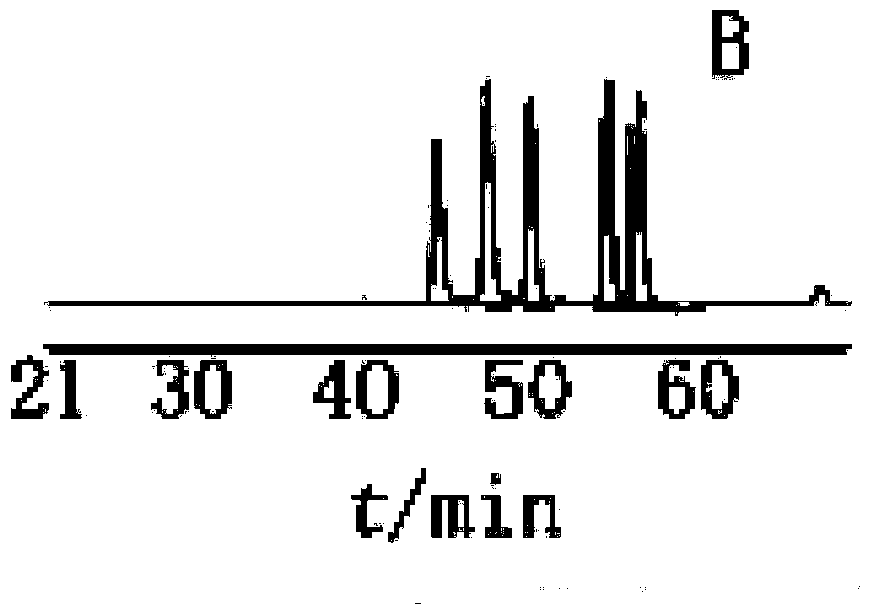

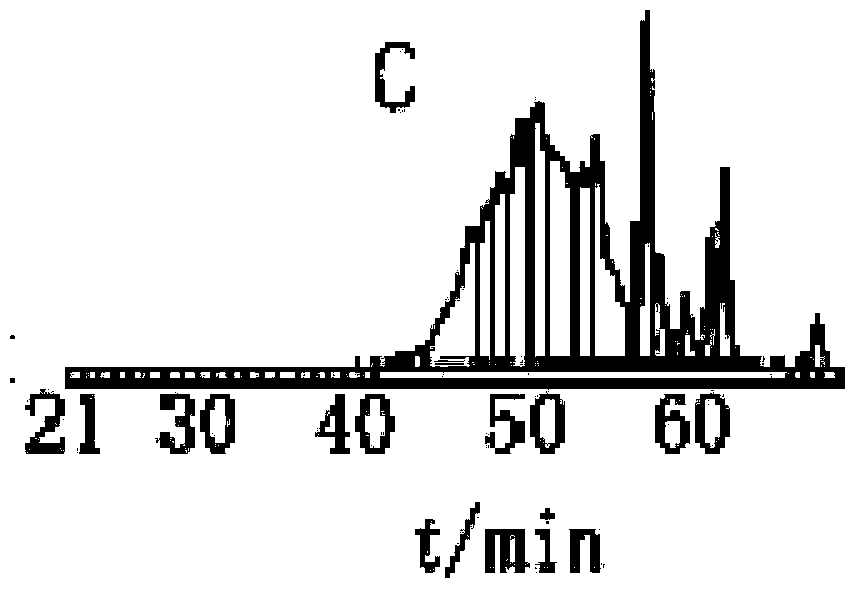

Image

Examples

Embodiment 1

[0055] 1. Take the fish skin and scales that are leftovers from aquatic product processing, wash them with water, add water 6 times the weight of the fish skin and scales, stir and heat to above 90°C, keep above 90°C for 30 minutes, filter and dry, and use the fish skin and scales for later use;

[0056] 2. Take the treated fish skin scales, add 0.05mol / L citric acid solution 4 times the weight of fish skin scales, ultrasonically treat for 4 hours, adjust the pH value to 6.0-7.5 with 10.0mol / L NaOH, filter and dry, Wash with water, filter dry, and set aside;

[0057] 3. Add 3 times the amount of water to the fish skin and scales, use a colloid mill to grind the fish skin and scale slurry, adjust the pH value to 8.0-8.5 with 10.0mol / L NaOH, and maintain the pH value within the range of 8.0-8.5, add fish skin Alcalase 2.4L FG with 0.1% fish scale weight, enzymatically hydrolyzed at 50°C-55°C for 100min, after enzymolysis, heat to above 90°C for 10min to inactivate the enzyme, co...

Embodiment 2

[0061] 1. Take the fish skin and scales that are leftovers from aquatic product processing, wash them with tap water, add water 12 times the weight of the fish skin and scales, stir and heat to above 90°C, keep above 90°C for 90 minutes, filter and dry, and use the fish skin and scales for later use;

[0062] 2. Take the treated fish skin and scales, add 0.05mol / L citric acid solution 12 times the weight of fish skin and scales for ultrasonic treatment for 8 hours, and use 10.0mol / L Na 2 CO 3 Adjust the pH value to 6.0-7.5, filter dry, wash with tap water, filter dry, and set aside;

[0063] 3. Add 8 times the amount of purified water to the fish skin and scale, use a colloid mill to grind the fish skin and scale slurry, and use 10.0mol / L Na 2 CO 3 Adjust the pH value to 8.0-8.5, maintain the pH value in the range of 8.0-8.5, add 0.8L of Neutrase with 0.4% weight of fish skin and scale, enzymatically hydrolyze at 50°C-55°C for 60min, and heat to above 90°C for 10min after en...

Embodiment 3

[0067] 1. Take the fish skin and scales that are leftovers from aquatic product processing, wash them with water, add 8 times the weight of fish skin and scales, water, stir and heat to above 90°C, keep above 90°C for 60 minutes, filter and dry, and use the fish skin and scales for later use;

[0068] 2. Take the treated fish skin and scale, add 0.05mol / L citric acid solution with a weight of 8 fish skin and scale, and ultrasonically treat it for 6 hours, adjust the pH value to 6.0-7.5 with 10.0mol / L NaOH, filter to dry, and wash with water Once, drained and set aside;

[0069] 3. Add 6 times the amount of purified water to the fish skin and scales, use a colloid mill to grind the fish skin and scale slurry, adjust the pH value to 8.0-8.5 with 10.0mol / L NaOH, and maintain the pH value within the range of 8.0-8.5, add fish Alcalase 2.4L FG with 0.2% weight of skin fish scales, 50°C-55°C for 180min, after enzymolysis, heat to above 90°C for 10min, carry out enzyme inactivation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com